Waterproof sealing structure for duct pipe connecting joint of shield tunnel

A shield tunnel segment and waterproof sealing technology, which is applied in tunnels, tunnel linings, shaft linings, etc., can solve the problems of structural waterproof failure, waterproof failure, mutual extrusion force reduction, etc., and achieve good self-sealing effect and processing Simple, low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

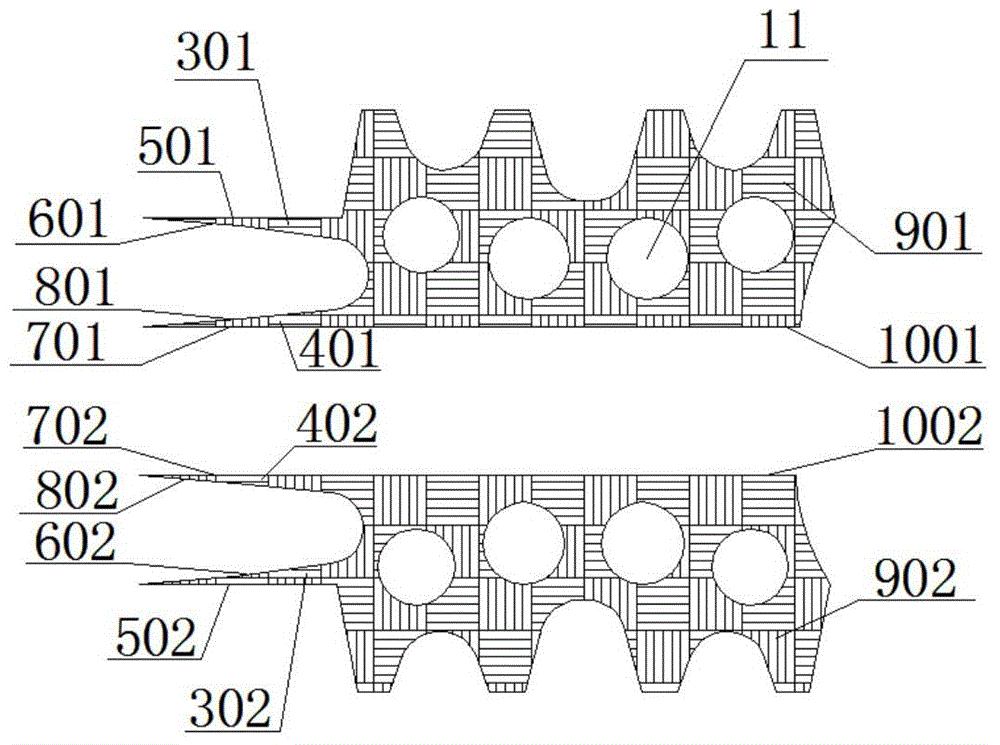

[0022] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

[0023] According to the background technology, the water pressure on the outside of the shield tunnel is unavoidable, and the effect of the water pressure on the segment waterproof gasket is also inevitable. The present invention utilizes the characteristics of the effect of the outer water pressure on the segment waterproof gasket. Combined with the characteristics of the leakage path when water leakage occurs, a waterproof gasket for the joints of shield tunnel segments is proposed to realize the self-sealing function of the waterproof gasket under the external water pressure.

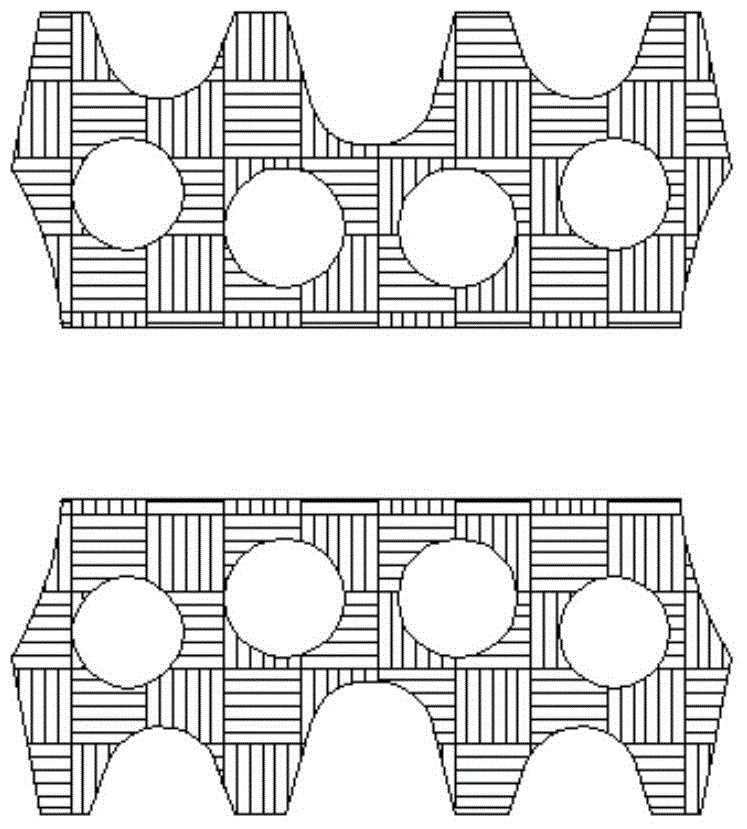

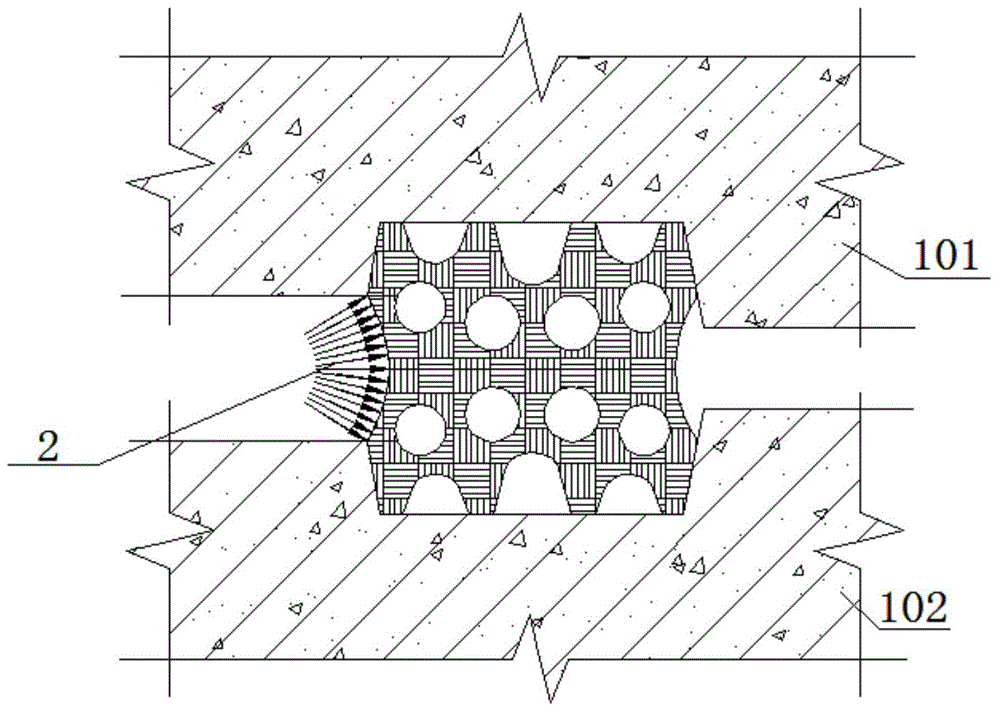

[0024] image 3 shows two opposing shield tunnel segment joint waterproof sealing structures of the present embodiment (wherein, the upper shield tunnel segment joint waterproof sealing structure and the lower shield tunnel segment joint waterproof sealing structure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com