A surface sizing agent for papermaking, and a papermaking method for improving paper strength and water resistance

A surface sizing agent and paper strength technology, which is applied in the field of papermaking to improve paper strength, surface sizing agent, and water resistance, can solve the problems of high cost, reduce application amount, improve strategic security, and high compressive strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0136] Example 1 Application of Na-based Bentonite Substituting Partial Surface Glue Starch in Container Board Production

[0137] 1. Materials

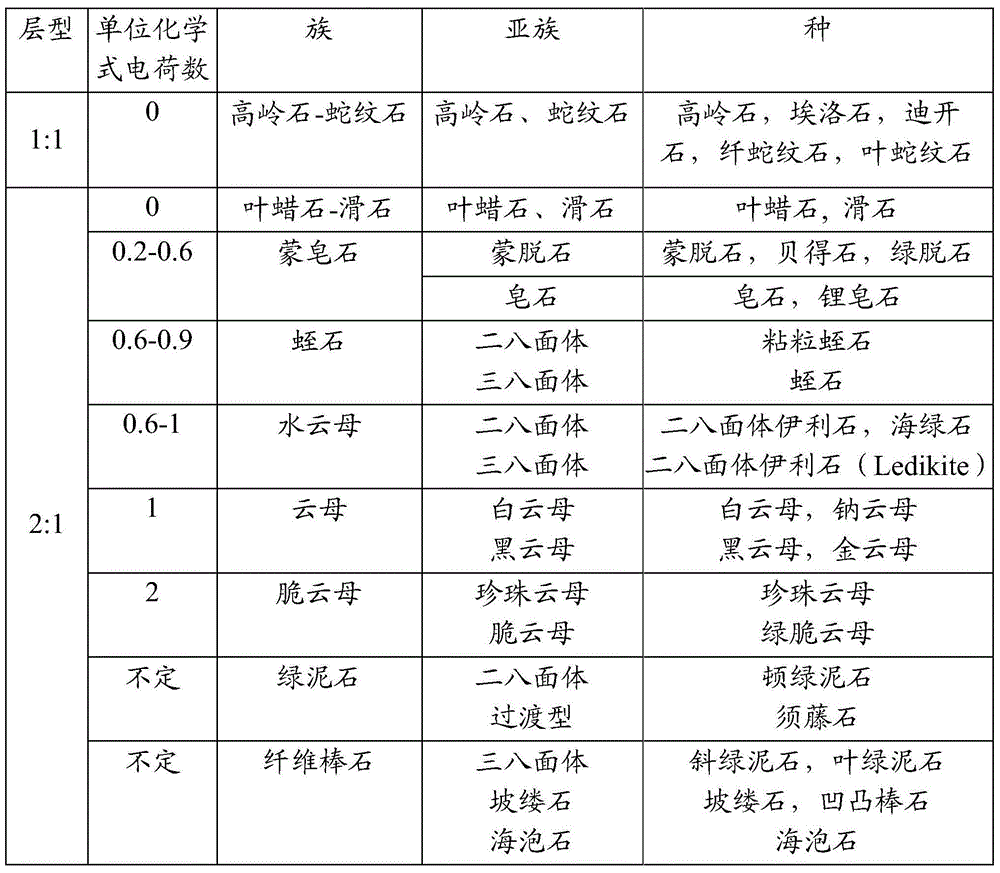

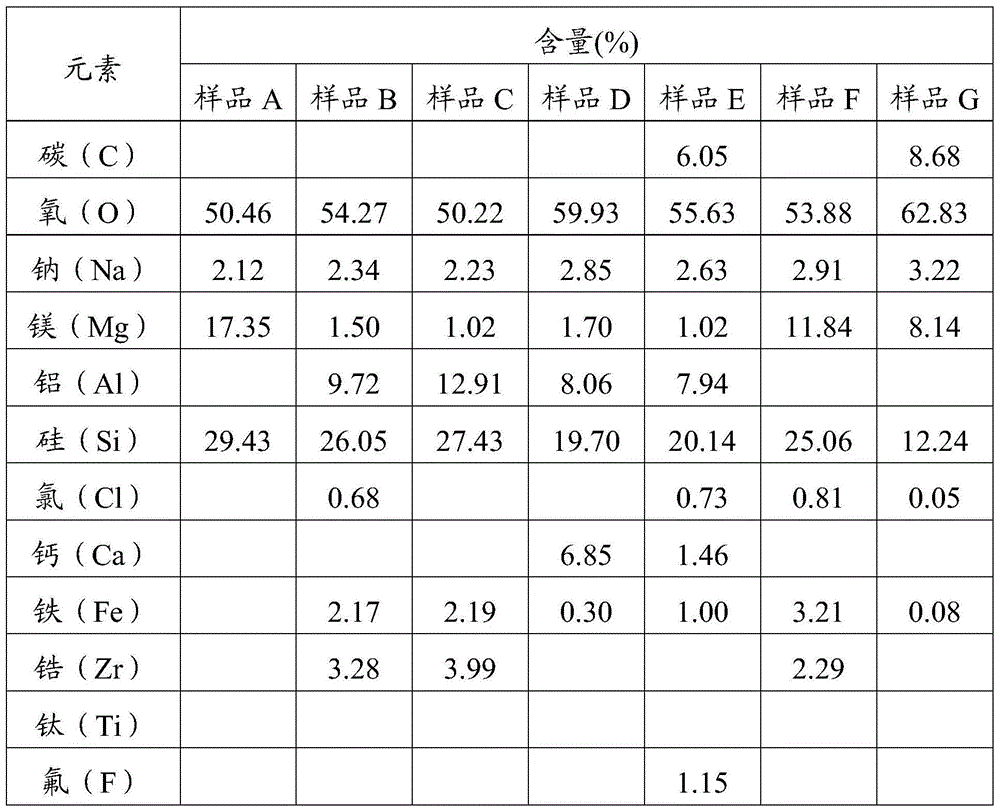

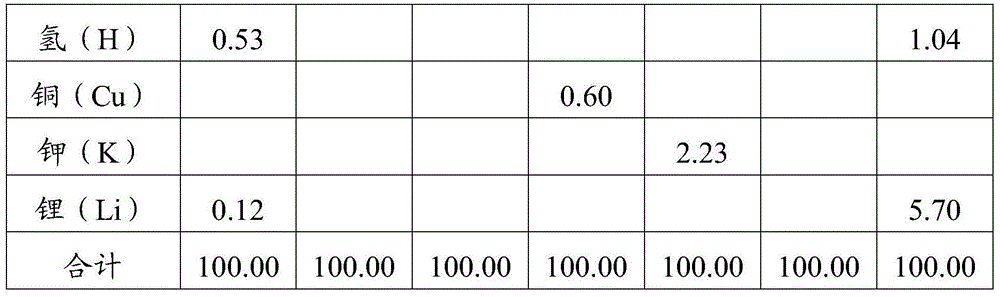

[0138] The starch is corn starch (Starch B200, a product of American Grain Process Company), the chemical primary color paste is from the chemical pulp mill (Macon, Georgia) of GPI Company in Georgia, the United States, and the sodium-based bentonite mineral product (sample B) is from Ruichenxing Biotechnology (Guangzhou ) Co., Ltd., its chemical structure analysis results are shown in Table 2.

[0139] Two, the steps of papermaking method are as follows:

[0140] (1) According to the TAPPI method, the grammage is 180g / m 2 The slices were dried to constant moisture;

[0141] (2) Get starch and put it in a beaker, add water to obtain a starch aqueous solution with a concentration of 8wt%, then heat to 100°C, and cook for 60 minutes under mechanical stirring at 1000RPM;

[0142] (3) Preparation of bentonite slurry: get 3.2g and 6.4...

Embodiment 2

[0153] Example 2 Application of Various Silicate Mineral Soils Substituting Part of Surface Adhesive Starch in the Production of Corrugated Paper with OCC Raw Materials

[0154] 1. Materials

[0155] The starch is corn starch or tapioca starch, which is provided by Dongguan Perfect Starch Co., Ltd.; the base paper is from Dongguan Tomorrow Paper Co., Ltd., which is obtained from the surface rubber machine when the paper machine breaks, and is 100% corrugated paper produced by OCC national waste; The chemical structure analysis results of bentonite minerals and other mineral products are shown in Table 2.

[0156] 2. The steps of the surface sizing method are as follows:

[0157] (1) According to the TAPPI method, the corrugated base paper is cut into A4 paper patterns, and then dried to a constant moisture content;

[0158] (2) Get starch and put it in a beaker, add water to 8% starch content, then heat to 100°C, add potassium persulfate and cook for 60 minutes under mechani...

Embodiment 3

[0170] Example 3 Application of Synthetic Layered Silicate Mineral Soil to Replace Part of Surface Gluten Starch in OCC Corrugated Paper Production

[0171] 1. Materials:

[0172] The starch is cassava starch, provided by Dongguan Perfect Starch Co., Ltd.; the base paper is taken from Dongguan Tomorrow Paper Co., Ltd., obtained from the surface rubber machine when the paper machine breaks, and it is corrugated paper produced by 100% OCC national waste; synthetic layered The chemical structure analysis results of the silicate (sample A) product are shown in Table 2.

[0173] 2. The steps of the surface sizing method are as follows:

[0174] (1) According to the TAPPI method, the corrugated base paper is cut into A4 paper patterns, and then dried to a constant moisture content;

[0175] (2) Get starch and put it in a beaker, add water to 8% starch content, then heat to 100°C, add potassium persulfate and cook for 60 minutes under mechanical stirring at 1000RPM;

[0176] (3) P...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com