A process for producing lubricating oil base oil from inferior heavy distillates

A technology for lubricating base oils and heavy distillates, which is applied in the petroleum industry, lubricating compositions, hydrotreating processes, etc., can solve the problems of reducing equipment investment and operating costs, and not improving the quality of hydrocracking unit products. Achieve the effects of increasing hydrogen partial pressure, reducing hydrogen sulfide and ammonia content, and optimizing process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

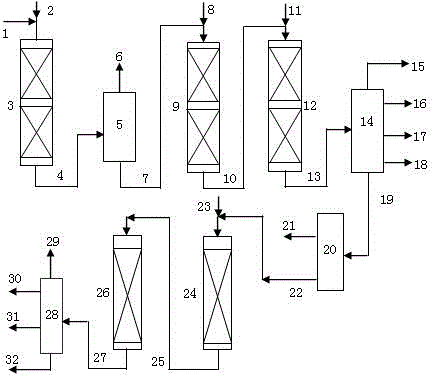

[0055] use figure 1 As shown in the process flow, the first stage is loaded with catalyst A, the second stage is filled with catalyst A, and the third stage is filled with FC-50 catalyst. The third stage of hydrocracking is a single-pass process, the refined nitrogen content of the second stage is controlled to be 15-25 μg / g, and the single-pass conversion rate of the cracking stage > 370 °C is controlled to ~70wt%.

[0056] The hydrocracking tail oil is all pre-fractionated to obtain light tail oil and heavy tail oil; the cutting temperature of light tail oil and heavy tail oil is 450°C. Heavy tail oil undergoes isomerization dewaxing reaction and supplementary refining reaction.

Embodiment 2

[0058] use figure 1 Process flow shown. Both the first stage and the second stage are filled with catalyst B. Others are the same as embodiment 1.

Embodiment 3

[0060] use figure 1 Process flow shown. Hydrofinishing catalyst A is used in the first stage, and hydrofinishing catalyst B is used in the second stage. Others are the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com