Method for synthesizing N-acetylmorpholine

A technology for acetylmorpholine and morpholine, applied in the field of synthesizing N-acetylmorpholine, can solve the problems of large equipment investment, long reaction time, large energy consumption and the like, and achieves the advantages of small equipment investment, high production efficiency and low energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

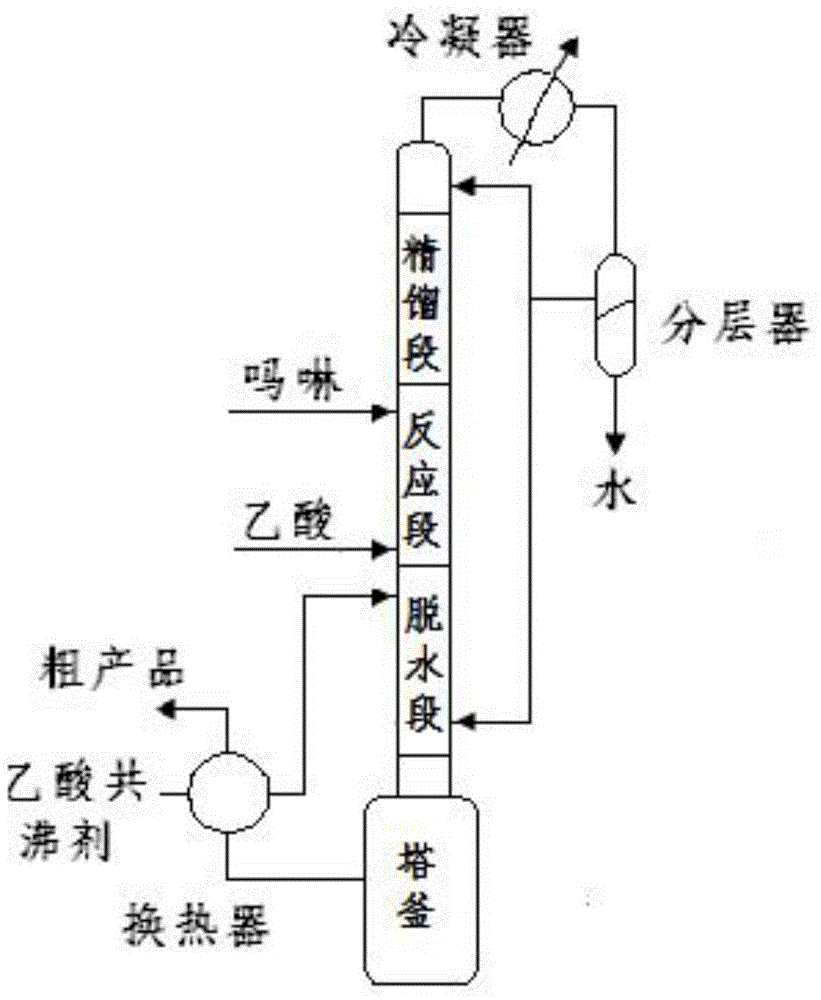

[0029] 1) The rectification tower includes a tower kettle and a tower column. The tower kettle is a 500ml three-necked bottle, heated by an electric heating mantle, and the tower column is divided into three sections. The section and rectification section are Φ20mm glass tubes, the outer wall is coated with thermal insulation conductive film, the height of rectification section is 300mm, and stainless steel triangular packing is installed inside, the height of reaction section and dehydration section are 200mm and 400mm respectively, and Φ2*2mm ceramic ring is installed inside.

[0030] The upper end of the tower kettle is connected to the dehydration section, the dehydration section is connected to the reaction section, and the reaction section is connected to the rectification section. The upper and lower parts of the reaction section are respectively equipped with a feed port, which are respectively the upper feed port of the reaction section and the lower feed port of the re...

Embodiment 2

[0035] 1) The rectification tower includes a tower kettle and a tower column. The tower kettle is a 500ml three-necked bottle, heated by an electric heating mantle, and the tower column is divided into three sections. The section and rectification section are Φ20mm glass tubes, the outer wall is coated with thermal insulation conductive film, the height of rectification section is 300mm, and stainless steel triangular packing is installed inside, the height of reaction section and dehydration section are 200mm and 400mm respectively, and Φ2*2mm ceramic ring is installed inside.

[0036] The upper end of the tower kettle is connected to the dehydration section, the dehydration section is connected to the reaction section, and the reaction section is connected to the rectification section. The upper and lower parts of the reaction section are respectively equipped with a feed port, which are respectively the upper feed port of the reaction section and the lower feed port of the re...

Embodiment 3

[0041] 1) The rectification tower includes a tower kettle and a tower column. The tower kettle is a 500ml three-necked bottle, heated by an electric heating mantle, and the tower column is divided into three sections. The section and rectification section are Φ20mm glass tubes, the outer wall is coated with thermal insulation conductive film, the height of rectification section is 300mm, and stainless steel triangular packing is installed inside, the height of reaction section and dehydration section are 200mm and 400mm respectively, and Φ2*2mm ceramic ring is installed inside.

[0042] The upper end of the tower kettle is connected to the dehydration section, the dehydration section is connected to the reaction section, and the reaction section is connected to the rectification section. The upper and lower parts of the reaction section are respectively equipped with a feed port, which are respectively the upper feed port of the reaction section and the lower feed port of the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com