Activation system for powder materials

A technology of powder materials and activators, which is applied in the field of processing systems, can solve the problems that powder materials cannot be fully utilized, and achieve the effects of effectively using energy, improving safety performance, and improving activation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

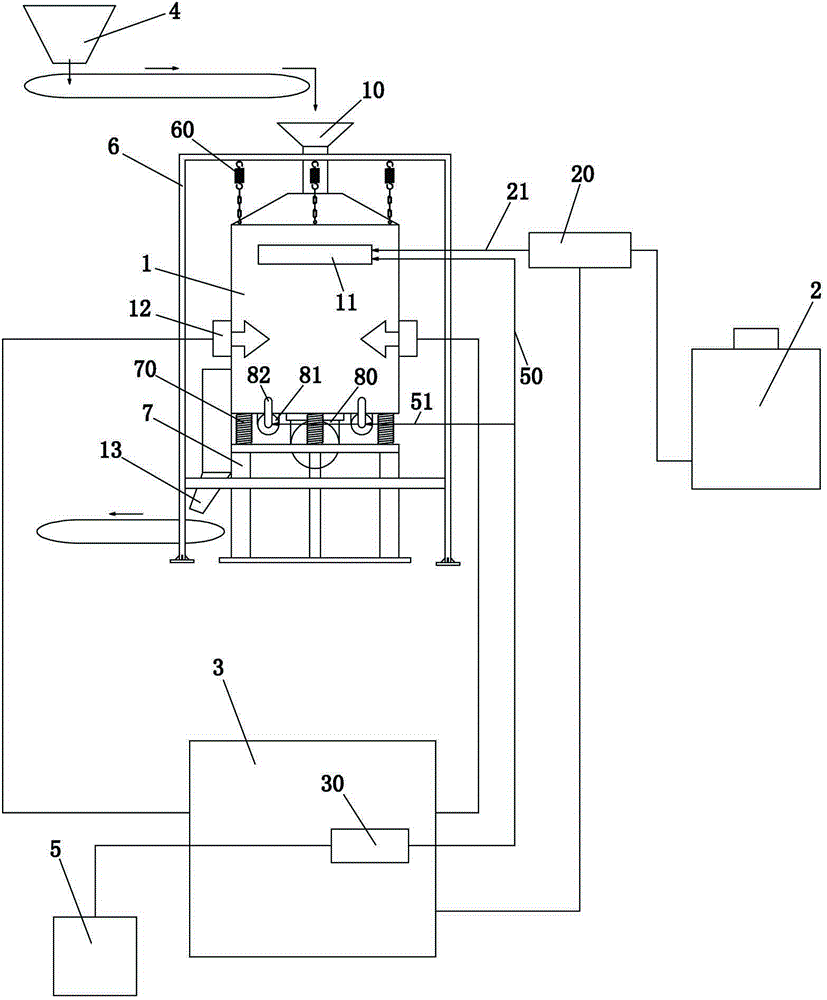

[0017] refer to figure 1 , an activation system for powder materials, comprising an activation chamber 1, an activator container 2 for storing an activator, and a controller 3; the material enters the activation chamber 1 quantitatively through a quantitative feeding device 4 from a feed port 10 at the top of the activation chamber, The activator is controlled by the metering device 20 from the activator container 2, and then input into the atomizing device 11 arranged on the activation chamber 1 through the activator pipeline 21, and the air compressor 5 passes through the first gas delivery pipe 50 The compressed air is input into the atomizing device 11 , and the air compressor 5 is controlled 30 by the regulating switch in the controller 3 . The activator interacts with the compressed air in the atomizing device 11 and is atomized into fine liquid droplets that are sprayed into the activation chamber 1 . The two sides of the activation chamber 1 are symmetrically equipped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com