Dual-winding synchronous control system and dual-winding synchronous control method for crane

A synchronous control and crane technology, applied in the direction of cranes, load hanging components, transportation and packaging, etc., can solve the problems of demanding requirements and complicated actual operation, achieve simple and reliable control, solve stability and safety, and have good application prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings.

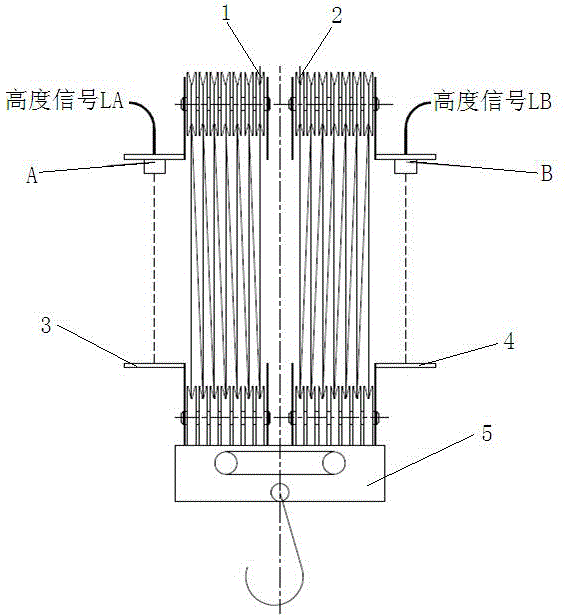

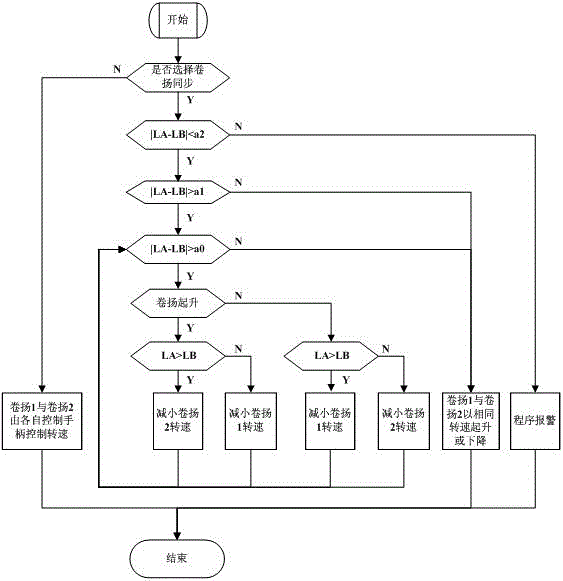

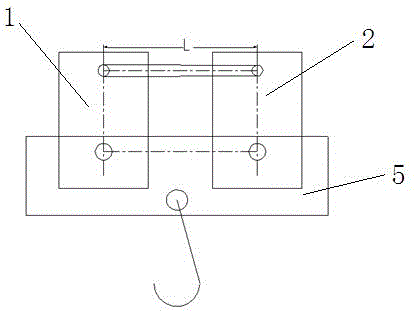

[0028] Such as figure 1 As shown, a double winch synchronous control system for a crane includes two laser range finders A and B symmetrically arranged on both sides of the crane arm head, the probes of each laser range finder are kept vertically downward, and the crane The arm head is connected to the lower hook 5 through two sets of independent speed-adjustable winches 1 and 2. The distance measuring baffles 3 and 4 extend from both sides of the hook 5, and each distance measuring baffle is located on the corresponding side. Directly below the laser range finder, the two laser range finders respectively measure the height of the corresponding side winch from the distance measuring baffle, and transmit the height signal to the controller, which controls the corresponding side through the winch speed regulating mechanism. The speed of the hoist, the laser range finder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com