Multi-cylinder combined spiral sieve grain cleaning machine

A grain sieving machine and combined technology, applied in the direction of filtering, solid separation, grille, etc., can solve the problems of small workload and large energy consumption, and achieve a large workload, good impurity removal effect, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

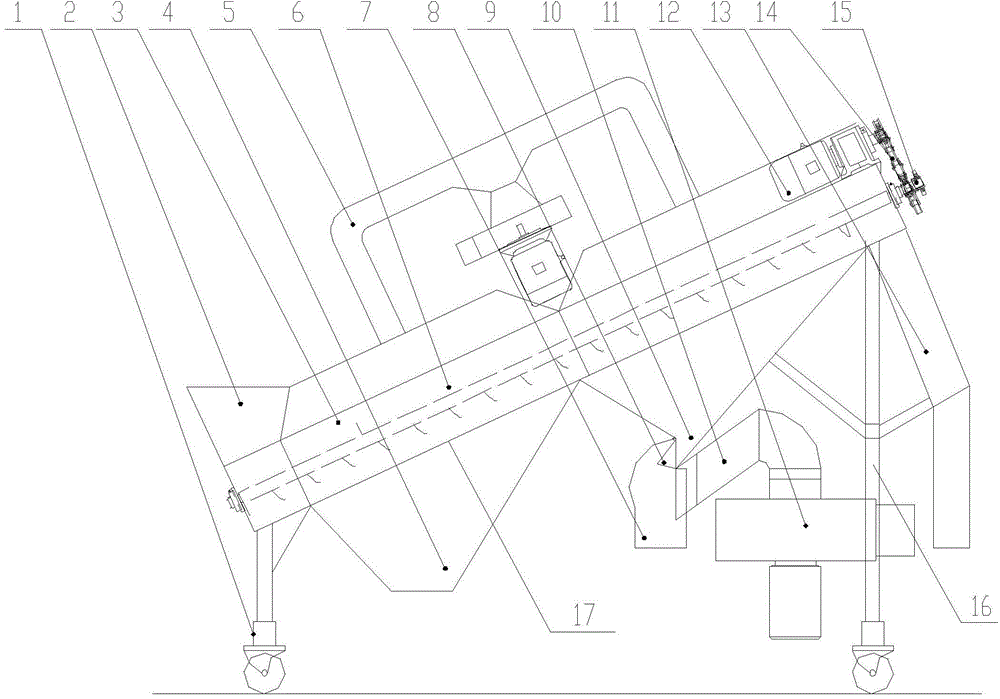

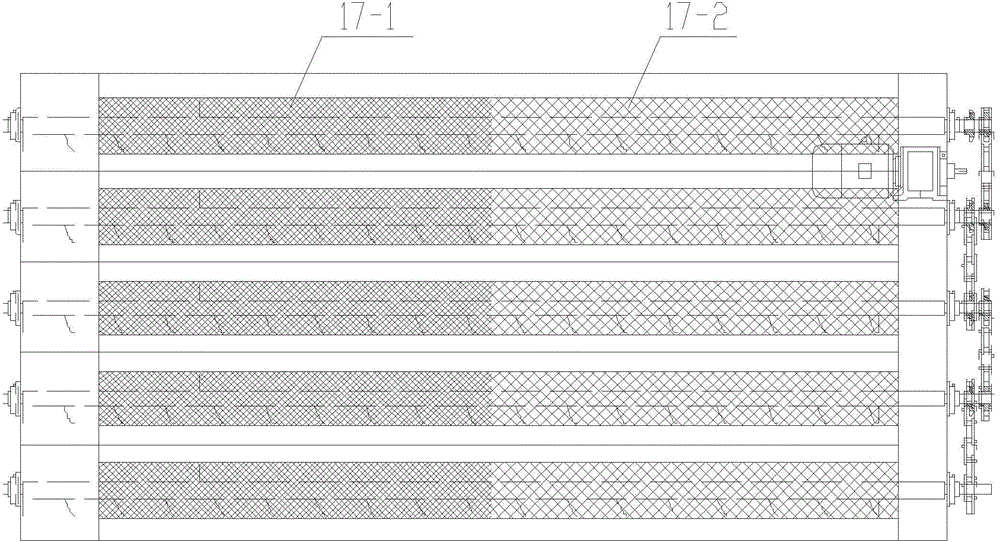

[0017] Such as figure 1 As shown, a multi-cylinder combined spiral sieve grain cleaning machine includes a frame 16, and a walking wheel 1 is arranged at the bottom of the frame 16, which can facilitate the movement of the grain cleaning machine. The top of the frame 16 is provided with a sieve shell 3, A set of screen cylinders 17 are arranged inside the screen shell 3, and the screen cylinders 17 are arranged obliquely. An auger 6 is installed in the screen cylinder 17, and one end of the auger shaft 15 in the auger 6 is connected to an auger drive motor 12 through a drive chain 14. The auger drive motor 12 drives the auger 6 to rotate in the screen cylinder 17. The screen cylinder 17 is divided into two parts, the front part is a fine screen cylinder body 17-1, and the rear part is a coarse screen cylinder body 17-1. 2. The fine-meshed sieve cylinder 17-1 is located at the lower end, and a feed hopper 2 is provided on the upper end of the fine-meshed sieve cylinder 17-1 for...

Embodiment 2

[0020] Such as figure 1 , figure 2 As shown, a multi-cylinder combined spiral sieve grain cleaning machine includes a frame 16, and a walking wheel 1 is arranged at the bottom of the frame 16, which can facilitate the movement of the grain cleaning machine. The top of the frame 16 is provided with a sieve shell 3, There are five sets of sieve cylinders 17 inside the sieve shell 3, and the sieve cylinders 17 are arranged obliquely. An auger 6 is installed inside the sieve cylinder 17, and one end of the auger shaft 15 in the auger 6 is connected to an auger drive motor through a drive chain 14. 12. The auger drive motor 12 drives the auger 6 to rotate in the screen drum 17. The screen drum 17 is divided into two parts, the front part is the fine screen drum 17-1, and the rear part is the coarse screen drum 17. -2, the fine mesh cylinder body 17-1 is located at the lower end, and a feed hopper 2 is arranged on the upper part of the fine mesh cylinder body 17-1, which is used f...

Embodiment 3

[0023] Such as figure 1 , figure 2 As shown, a multi-cylinder combined spiral sieve grain cleaning machine includes a frame 16, and a walking wheel 1 is arranged at the bottom of the frame 16, which can facilitate the movement of the grain cleaning machine. The top of the frame 16 is provided with a sieve shell 3, There are five sets of sieve cylinders 17 inside the sieve shell 3, and the sieve cylinders 17 are arranged obliquely. An auger 6 is installed inside the sieve cylinder 17, and one end of the auger shaft 15 in the auger 6 is connected to an auger drive motor through a drive chain 14. 12. The auger drive motor 12 drives the auger 6 to rotate in the screen drum 17. The screen drum 17 is divided into two parts, the front part is the fine screen drum 17-1, and the rear part is the coarse screen drum 17. -2, the fine mesh cylinder body 17-1 is located at the lower end, and a feed hopper 2 is arranged on the upper part of the fine mesh cylinder body 17-1, which is used f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com