Comprehensive efficient organic waste crusher

An organic waste, comprehensive technology, applied in the field of comprehensive organic waste high-efficiency shredder, can solve the problems of poor adaptability, large volume difference, different moisture content, etc., to achieve reduced noise and energy consumption, strong and consistent crushing ability good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

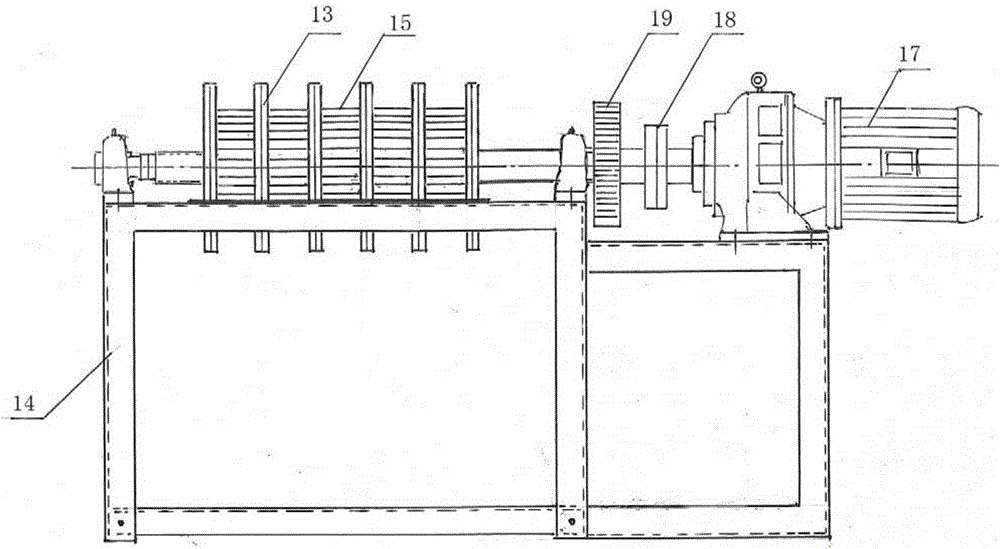

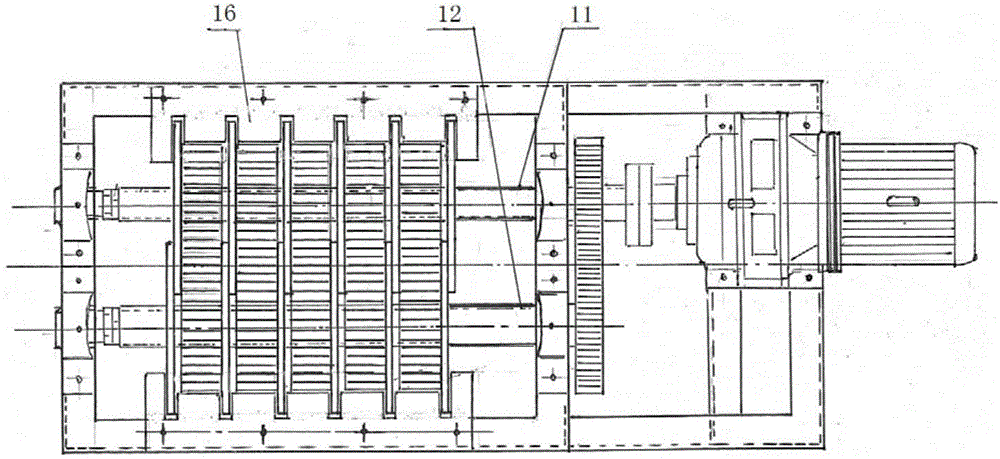

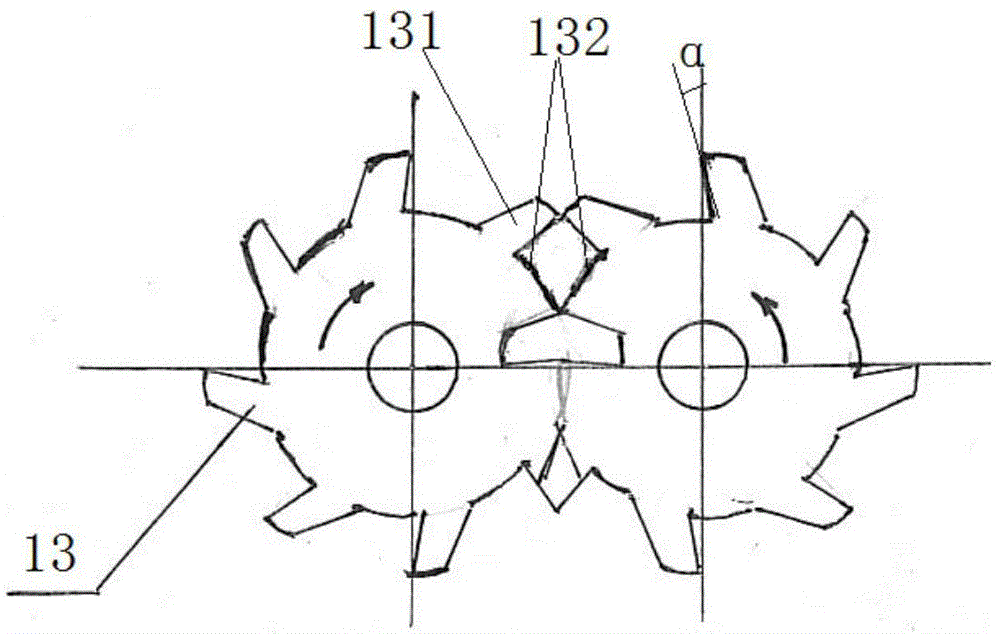

[0020] Such as figure 1 , 2 , 3 and 4, a comprehensive organic waste high-efficiency shredder includes a first synchronous shaft 11, a second synchronous shaft 12, multiple pairs of shearing knives 13, a frame 14 and a driving device, the first The synchronous shaft 11, the second synchronous shaft 12 and the driving device are installed on the frame 14, and the driving device drives the first synchronous shaft 11 and the second synchronous shaft 12 to rotate synchronously, and the paired shearing knives 13 are respectively installed on the first synchronous shaft 11 and the second synchronous shaft 12, the shearing knife 13 includes a cutterhead and the sawtooth 131 arranged on the outer edge of the cutterhead, the outer edge of the cutterhead between the sawtooth 131 of the shearing knife 13 is a cutting edge 132, and the cutterhead The center of the center has a shaft hole for the installation of the shearing knife 13, and the pair of shearing knives 13 are overlapped and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com