Combined feeding distributor

A feed distributor and distributor technology, applied in the directions of feeding devices, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of liquid disturbance in the tower kettle, affecting the distribution effect, and low occupation, so as to reduce the disturbance. , the effect of reducing entrainment and even distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific implementation examples.

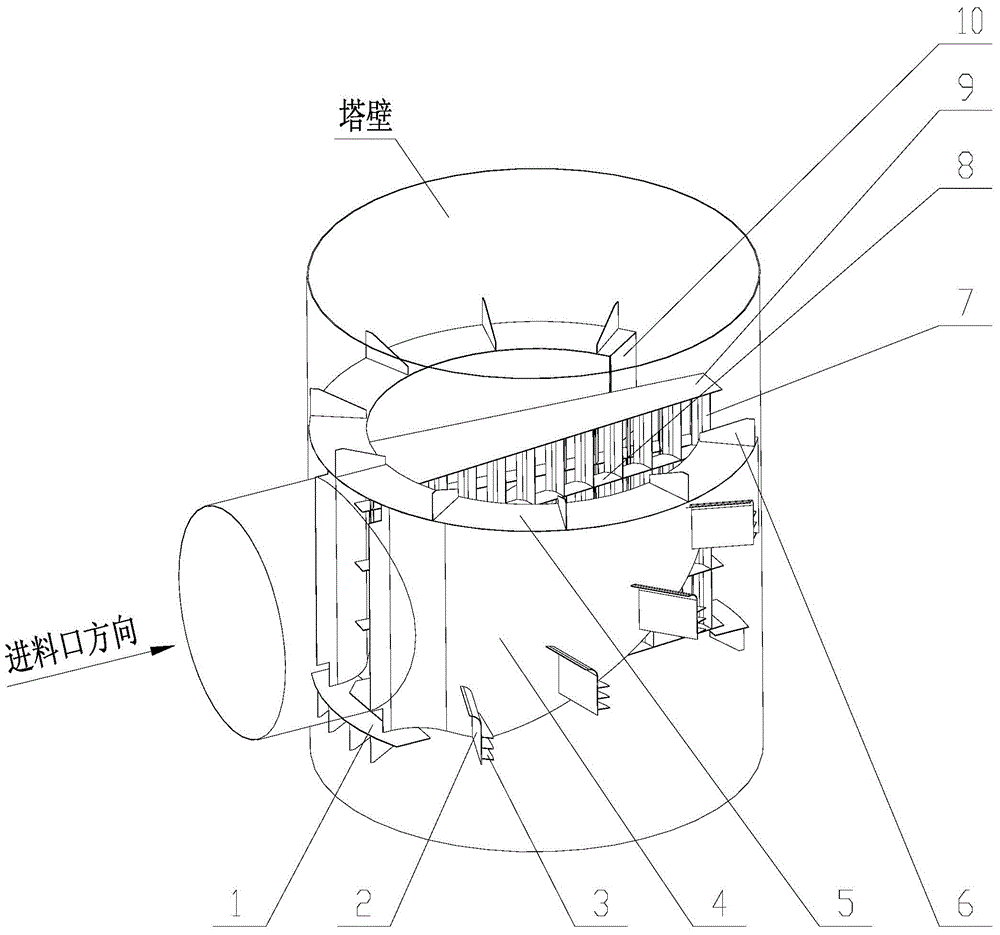

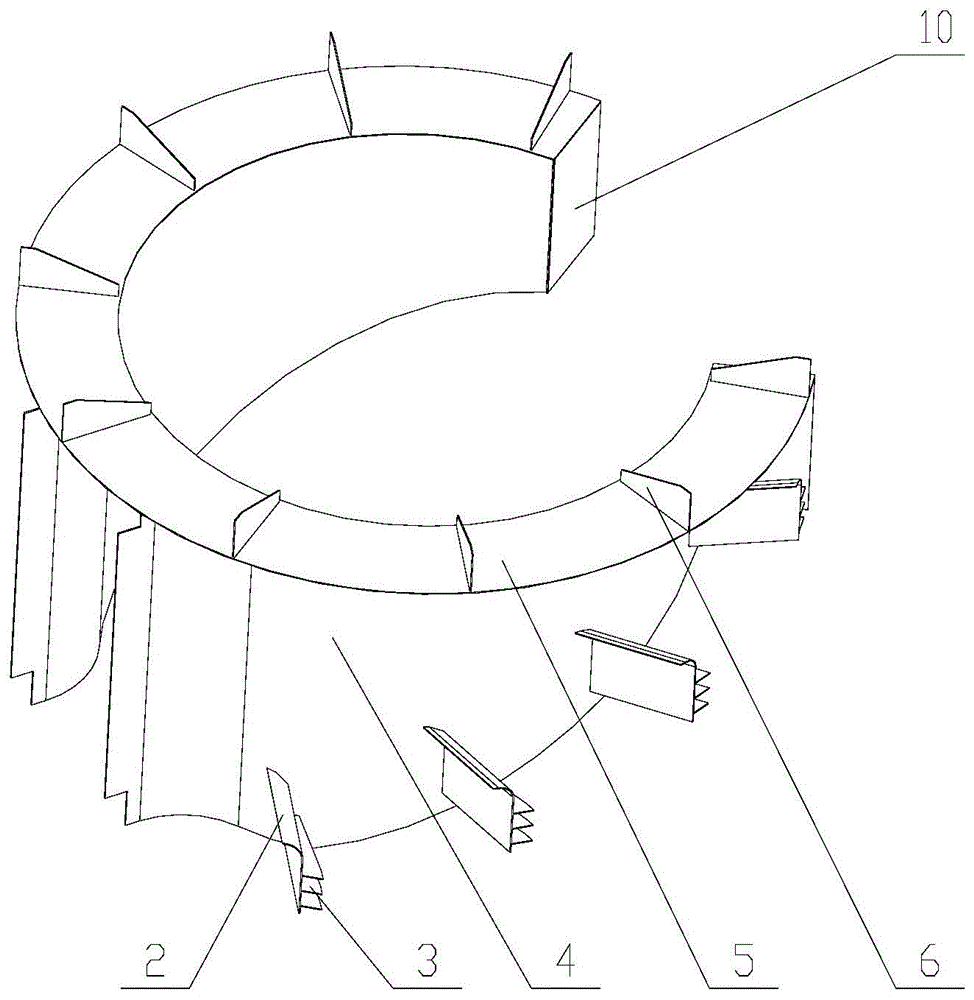

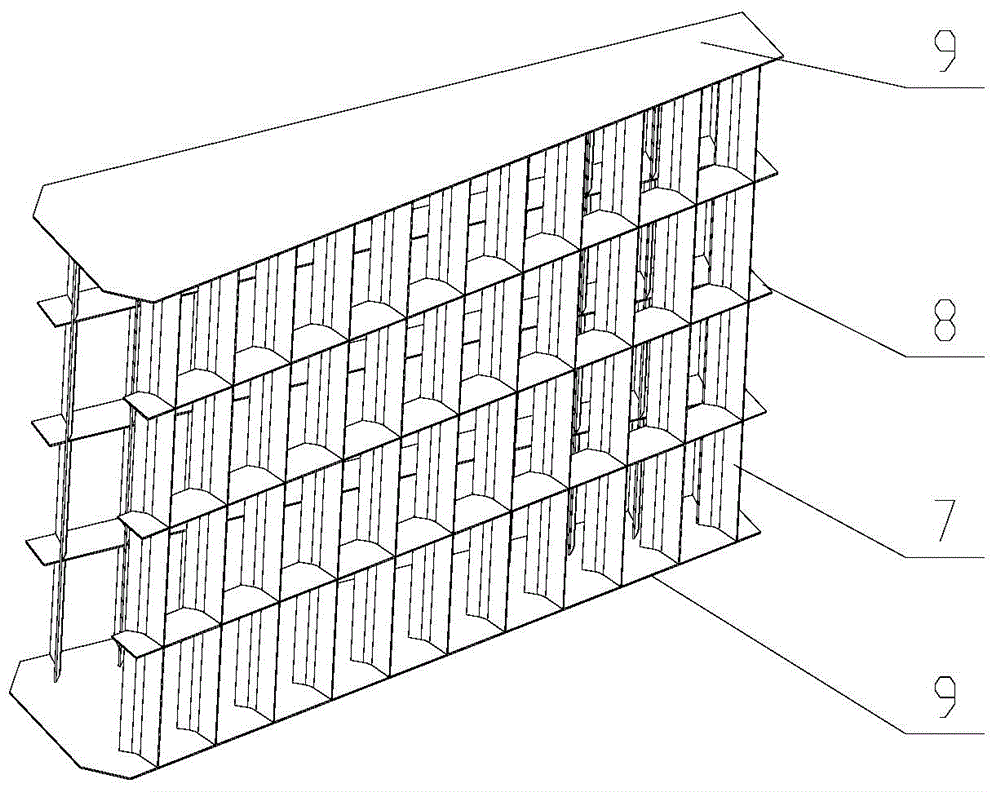

[0019] The combined feed distributor of the present invention is based on the specific implementation of the above-mentioned double tangential feed distributor and double-row blade feed distributor, and combines the two distributors.

[0020] like figure 1 As shown, the feed inlet with a circular cross-section is divided into left and right tangential feed areas and a middle radial feed area by the inner sleeve 4 of the double tangential feed distributor. By adjusting the size of the inner sleeve 4, the The areas of the left and right tangential feed areas and the middle radial feed area are approximately equal. Double tangential feed distributors are set in the left and right tangential feed areas, and double-row blade feed distributors are set in the middle radial feed area. Both the double tangential feed distributor and the do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com