A kind of hob cutter of sesame seed dough forming machine and its processing method

A processing method and the technology of rolling cutters, which are applied in the fields of dough forming machinery or equipment, baking, food science, etc., can solve the problems that the shapes of cutters cannot be completely matched, damage the plasticity of raw materials, and the shape of cutters is irregular, etc., to achieve Create simple, quality-enhancing, smooth-surfaced effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be specifically described below in conjunction with the accompanying drawings and embodiments.

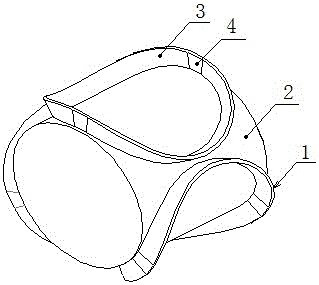

[0020] figure 1 Shown is a schematic diagram of the three-dimensional structure of the present invention.

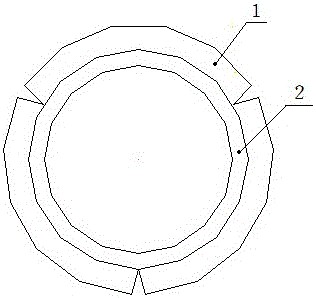

[0021] The present invention comprises a hob cutter 1 and a hob cutter fixing pipe 2, and three hob cutters 1 are evenly arranged on the outer surface of the hob cutter fixing pipe 2.

[0022] The hob cutter 1 is welded by two long-arc plates 3 and two short-arc plates 4 at intervals. The outer diameters of the fixed pipes 2 are the same, and the inner circular arc of the hob cutter 1 is directly welded to the outer surface of the hob cutter fixed pipe 2 .

[0023] A gap of 5-10 mm is provided between the outer edges of the three hob cutters 1 distributed on the hob cutter fixing pipe 2 .

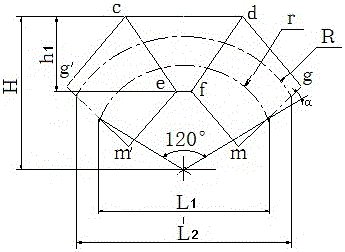

[0024] The processing method of the present invention comprises the steps of decomposing the projection diagram by using the graphic projection method,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com