A gas diffusion electrode and its preparation method

A gas diffusion electrode and gas diffusion layer technology, applied in the direction of electrodes, electrode shapes/types, electrolysis components, etc., can solve the problems of difficult gas-liquid-solid three-phase reaction balance, weak electrode mechanical strength, and difficulty in industrialized production, etc. The effect of reducing the ability of hydrogen peroxide side reaction, excellent water pressure resistance, and improving electrocatalytic ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

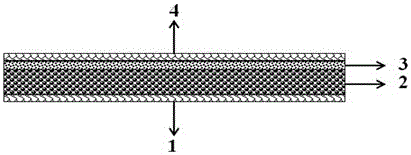

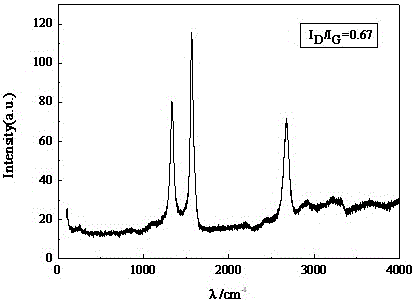

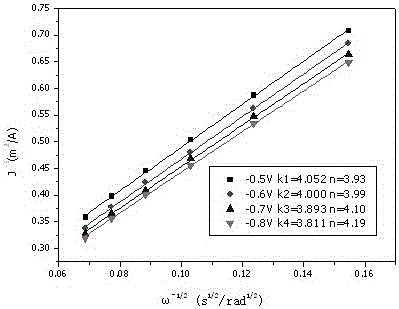

[0039] The carbon black with high graphitization degree used is obtained by graphitizing carbon black (Vulcan XC-72) in a high-temperature graphitization furnace at 2700°C for 6-10 h. The Raman spectrum for testing the degree of graphitization is as follows: figure 2 As shown, its Raman spectrum I D / I G 0.67, silver-plated nickel foam was prepared by electroplating, nickel foam was purchased from Heze Tianyu Technology Development Co., Ltd., acidified carbon black with high graphitization degree was prepared by heating graphitized carbon black in nitric acid (68% mass fraction) at 120°C ) solution was condensed and refluxed for 6-10 h.

[0040] 1) Weigh 0.4~2g high graphitization degree carbon black and disperse it in isopropanol aqueous solution containing 0.4~1g triton, in which isopropanol is 40mL, water is 10~25mL, and then the slurry solution is ultrasonically sheared After cutting for 60 minutes, add 1-2 g of polytetrafluoroethylene emulsion (D-110) with a mass fract...

Embodiment 2

[0045] The high graphitization degree carbon black used is obtained by graphitizing carbon black (Vulcan XC-72) at 2600°C for 2 to 15 hours, and its Raman spectrum I D / I G The silver-plated nickel foam is prepared by electroplating. The nickel foam is purchased from Heze Tianyu Science and Technology Development Co., Ltd. The acidified carbon black with high graphitization degree is obtained by heating graphitized carbon black at 140°C in nitric acid (mass fraction: 68%) obtained by condensing and refluxing in the solution for 6 to 10 hours.

[0046] 1) Weigh 1~3g high graphitization degree carbon black and disperse it in isopropanol aqueous solution containing 0.4~3g triton, in which isopropanol is 40mL, water is 4~16mL, and then the slurry solution is ultrasonically sheared After cutting for 60 minutes, add 0.4 to 1.5 g of polytetrafluoroethylene emulsion (D-110) with a mass fraction of 60%, and continue to shear and disperse for 10 minutes. After the dispersion is complet...

Embodiment 3

[0051] The high graphitization degree carbon black used is obtained by graphitizing carbon black (Vulcan XC-72) in a high temperature graphitization furnace at 2900°C for 2 to 15 hours, and its Raman spectrum I D / I G 0.3 to 0.6, silver-plated nickel foam is prepared by electroplating, and the nickel foam is purchased from Heze Tianyu Technology Development Co., Ltd. The acidified carbon black with high graphitization degree is prepared by heating graphitized carbon black at 160°C in nitric acid (mass fraction: 68%) obtained by condensing and refluxing the solution for 6-10 hours.

[0052] 1) Weigh 2-4g high graphitization degree carbon black and disperse it in isopropanol aqueous solution containing 2.5-4g triton, in which isopropanol is 40mL, water is 20-40mL, and then the slurry solution is ultrasonically sheared After cutting for 60 minutes, add 1.8 to 4 g of polytetrafluoroethylene emulsion (D-110) with a mass fraction of 60%, and continue to shear and disperse for 10 mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com