Wiring device special for power measurement

A wiring device and power measurement technology, applied in the direction of the housing of the measurement device, etc., can solve the problems of the secondary side not being able to connect in time, missing wiring, and long wiring time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

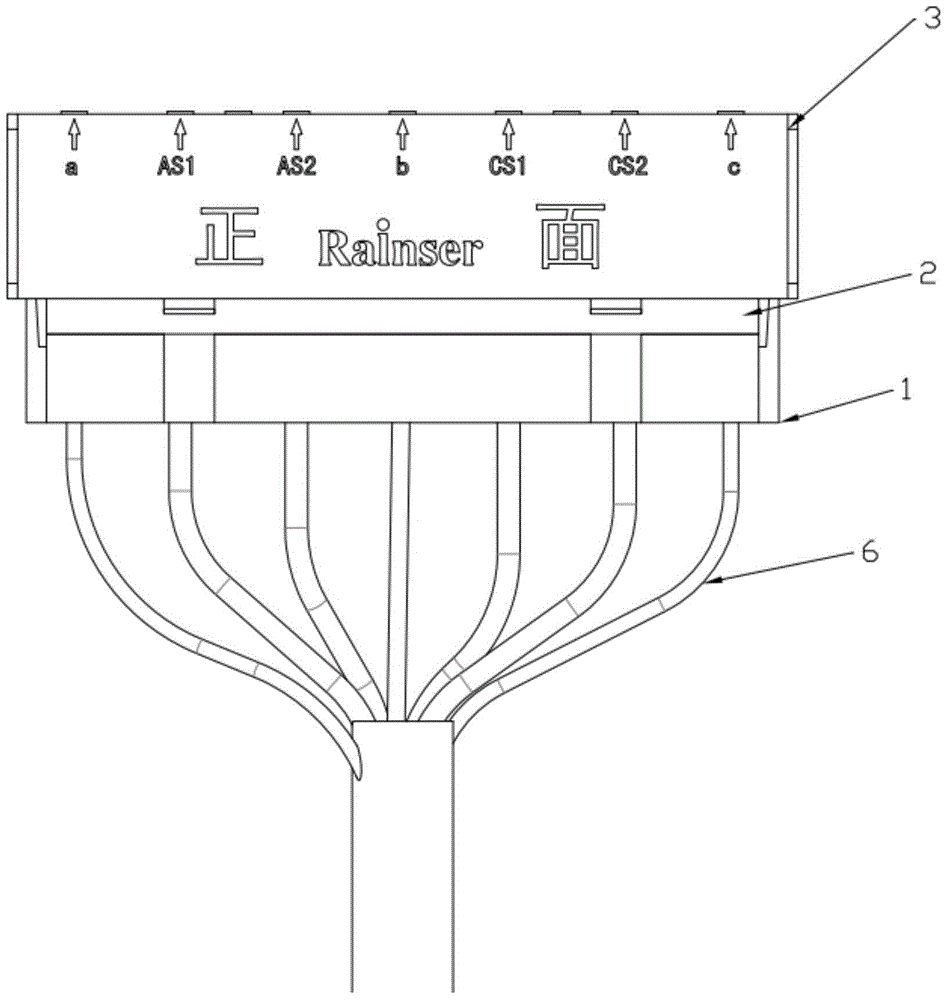

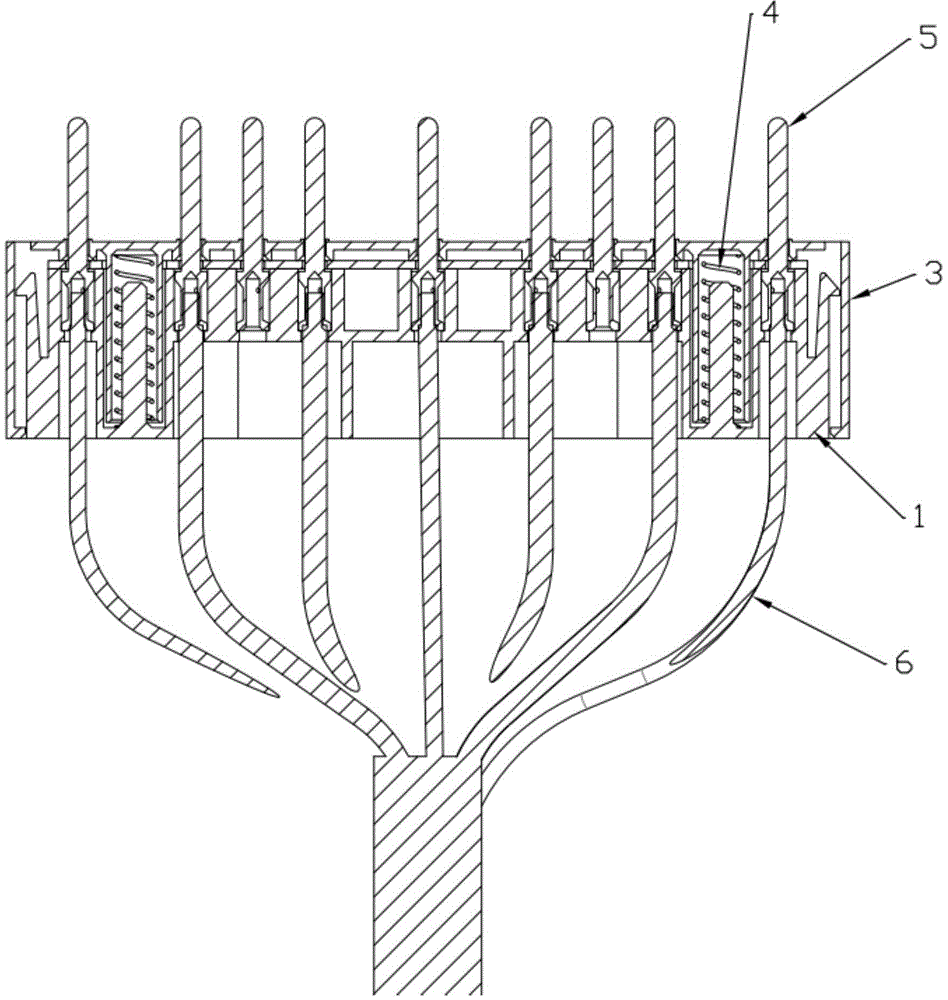

[0014] see figure 1 , a special wiring device for power metering in the figure, including a casing, a main body inserted into the casing, and several cold pressing pins fixed on the main body and protruding from the casing, the feature is: the main body is provided with several installation A cold-pressing needle chamber, the tail of the cold-pressing needle is placed in the cold-pressing needle chamber, and a cold-pressing needle hole corresponding to the cold-pressing needle chamber is provided on the shell, and the front part of the cold-pressing needle passes through the cold-pressing needle The crimping needle hole extends out of the shell; the rear part of the crimping needle chamber is provided with a threading hole, and the wire is inserted into the tail of the crimping needle through the threading hole;

[0015] A pressing plate is installed on the main body, and the pressing plate fixes the cold pressing needle on the main body, and a buckle structure is arranged bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com