Co3V2O8 sensing electrode and three-dimensional three-phase boundary-based YSZ electrode mixed potential NO2 sensor and preparation method thereof

A hybrid potential-type, sensitive electrode technology, applied in instruments, scientific instruments, material analysis through electromagnetic means, etc., can solve the problems of sensor sensitivity limitation, small construction area, limited performance improvement, etc., and achieve good thermal stability and The effect of chemical stability, simple preparation method, and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

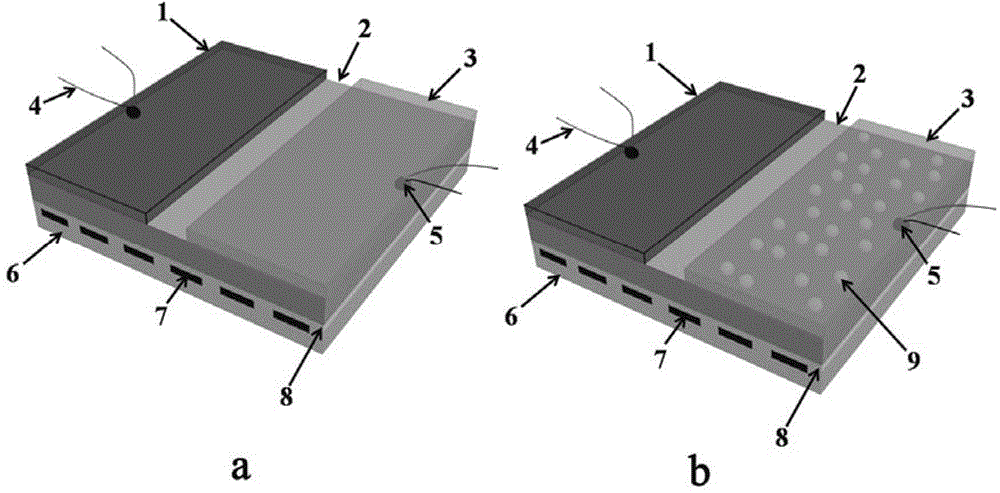

Method used

Image

Examples

Embodiment 1

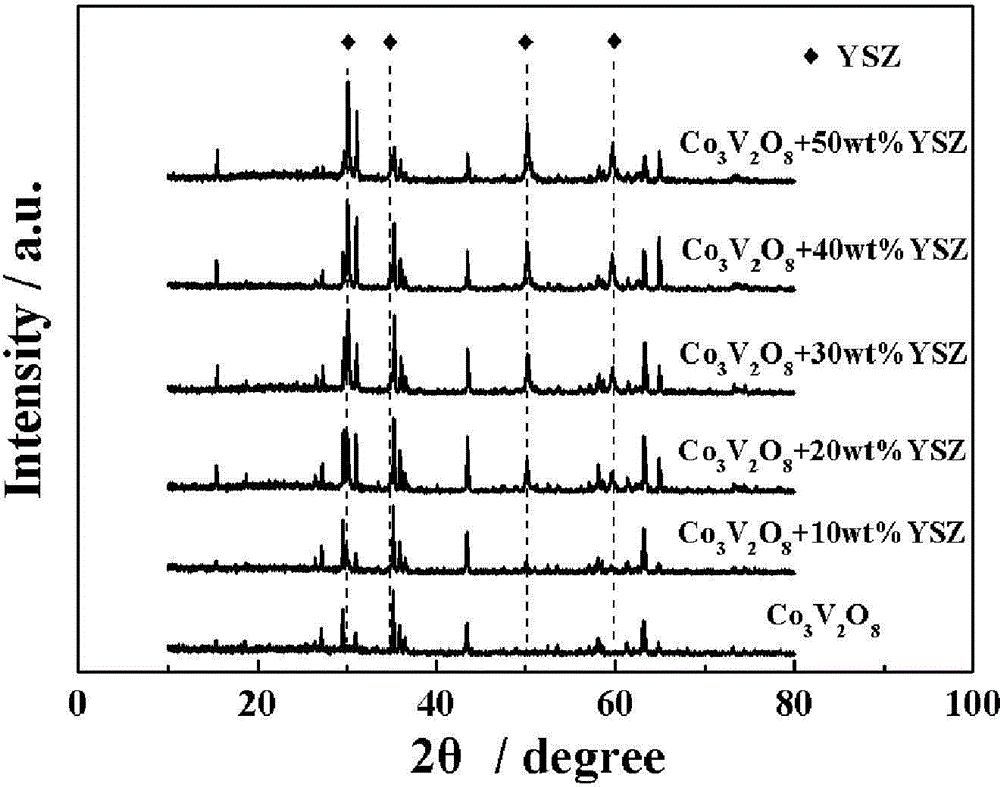

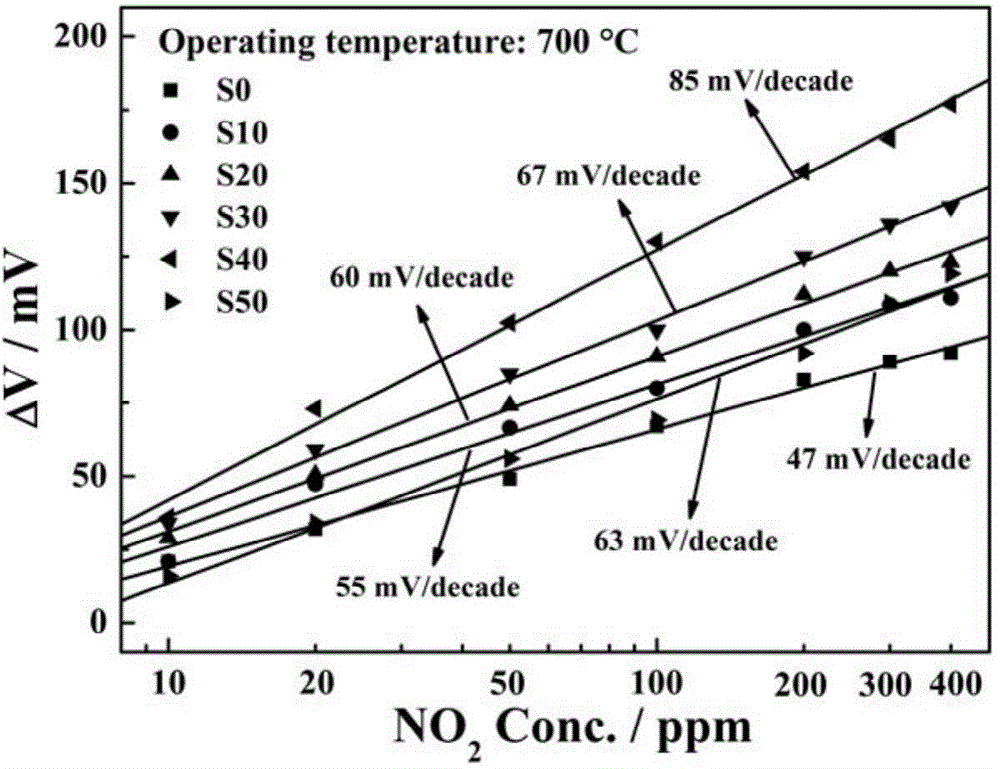

[0041] Co prepared in Comparative Example 1 3 V 2 o 8 And the mixed material of 10wt% YSZ particles is used as a sensitive electrode material to make NO 2 The sensor, its manufacturing process is:

[0042] The Co prepared by the aforementioned method 3 V 2 o 8 +10wt% YSZ particles were fully ground with a mortar and evenly used as a sensitive electrode material. The fabrication process of the device was the same as that of Comparative Example 1, and it was marked as sensor S10.

Embodiment 2

[0044] Co prepared in Comparative Example 1 3 V 2 o 8 And the mixed material of 20wt% YSZ particles is used as a sensitive electrode material to make NO 2 The sensor, its manufacturing process is:

[0045] The Co prepared by the aforementioned method 3 V 2 o 8 +20wt% YSZ particles were fully ground with a mortar and used as a sensitive electrode material, and the device manufacturing process was the same as that of Comparative Example 1, marked as sensor S20.

Embodiment 3

[0047] Co prepared in Comparative Example 1 3 V 2 o 8 And the mixed material of 30wt% YSZ particles is used as a sensitive electrode material to make NO 2 The sensor, its manufacturing process is:

[0048] The Co prepared by the aforementioned method 3 V 2 o 8 +30wt% YSZ particles were fully ground with a mortar and used as a sensitive electrode material. The device manufacturing process was the same as that of Comparative Example 1, marked as sensor S30.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com