Intelligent dry-oil centralized lubrication system for coal mining machine

A centralized lubrication and capable technology, applied in the direction of engine lubrication, lubricating parts, lubricating oil control valves, etc., can solve problems such as increased labor intensity of operators, damage to friction pairs, shearer shutdown, etc., and achieve effective and intelligent lubrication state. Precise monitoring and precise grease delivery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In conjunction with accompanying drawing, the specific embodiment of the present invention is described further:

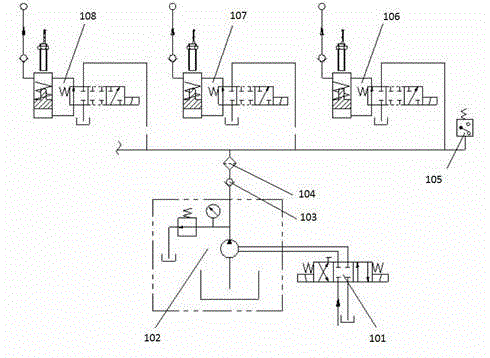

[0036] Such as figure 1 The intelligent dry oil centralized lubrication system of the coal mining machine shown is set in the hydraulic pump station cavity of the coal mining machine frame body, including a three-position four-way explosion-proof solenoid valve 101, a dry oil lubrication pump 102, a one-way valve 103, a filter device 104, explosion-proof pressure controller 105 and several explosion-proof intelligent electromagnetic distributors; the oil inlet of the three-position four-way explosion-proof solenoid valve 101 is connected to the hydraulic pump station, and the dry oil lubrication pump 102 is connected to the three-position four-way explosion-proof solenoid valve 101 Connection, dry oil lubrication pump 102 is connected with check valve 103, filter 104 is connected with check valve 103, explosion-proof pressure controller 105 is connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com