Device for controlling flow direction of fluid through temperature

A temperature control and fluid technology, applied in the valve operation/release device, valve device, pipeline protection through thermal insulation, etc., can solve the problems of influence, increase the workload of staff, heat loss, etc., to achieve convenient use and reduce walking Distance, the effect of reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

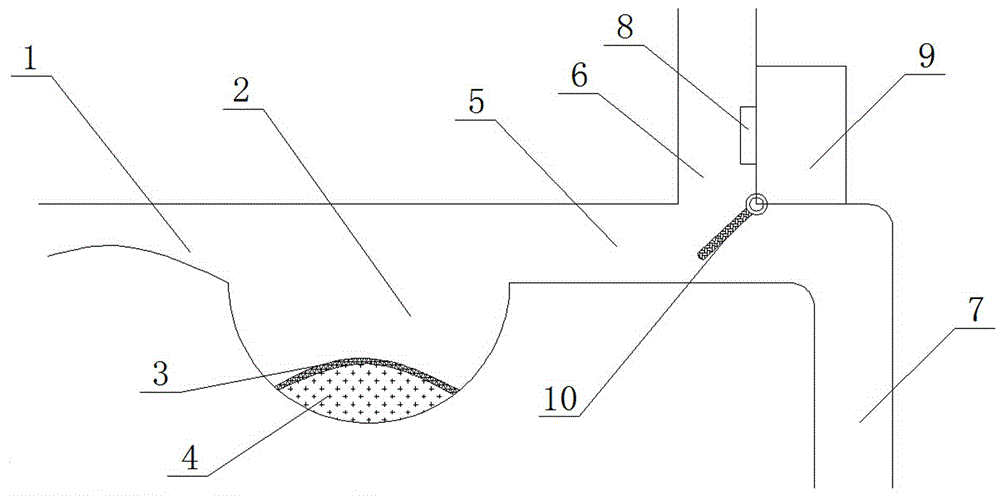

[0026] The main structure of this embodiment, such as figure 1 As shown, including a buffer pipeline and a valve system, the fluid delivery pipe 1 of the buffer pipeline communicates with the fluid inlet pipe 5 of the valve system;

[0027] The fluid delivery tube 1 is included, and the middle part of the fluid delivery tube 1 is sunken to form a mixing chamber 2. An elastic layer 3 is sealed inside the mixing chamber 2. The elastic layer 3 and the inner wall of the mixing chamber 2 form an expansion bag. Filled with expansion medium4. A concave mixing chamber 2 is added in the fluid delivery pipe, so that when the cold fluid in the pipe flows through the fluid delivery pipe 1, it enters the mixing chamber 2 first, and then the hot fluid enters the mixing chamber 2 to mix with the cold fluid, so that the overall temperature of the fluid Elevation; the mixing chamber 2 is also sealed with an elastic layer 3, and the inside of the elastic layer 3 is filled with an expansion med...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com