Hydraulic rock-soil milling and excavating equipment and method for tunnel in soft and weak surrounding rock

A technology for weak surrounding rock and tunnels, which is applied in the field of hydraulic geotechnical milling and excavation of weak surrounding rock tunnels, can solve the problems of tunnel excavation control deviation, large terrain fluctuations, and difficulty in application, and achieves easy construction, low excavation vibration, and safety. low risk effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

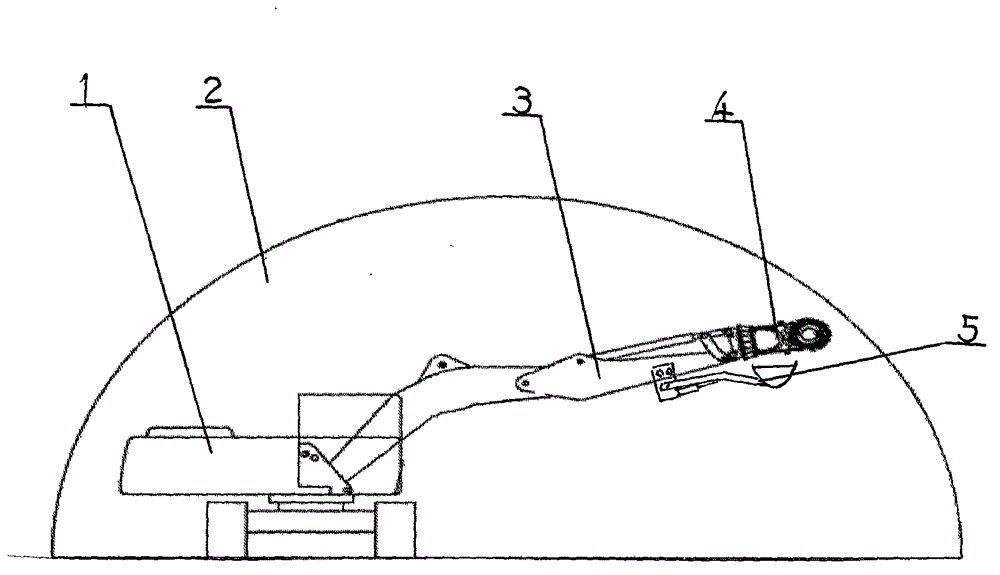

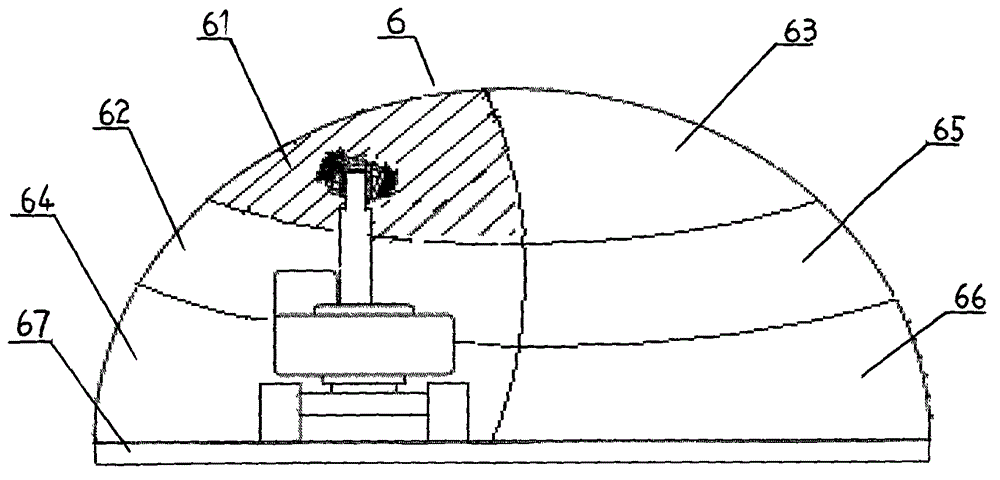

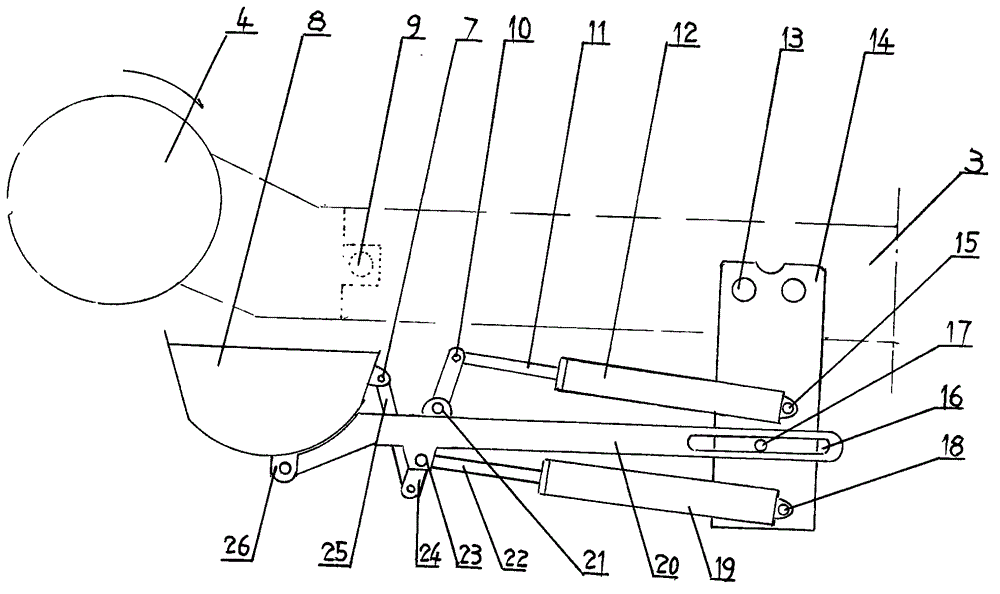

[0027] like Figure 1 to Figure 4 As shown, a hydraulic rock-soil milling method for tunnels with weak surrounding rocks uses milling equipment for excavation. In this method, the tunnel working surface 2 is divided into six work areas that are sequentially carried out and excavated in the surrounding rock 6, including Follow the steps below:

[0028] (1) For the advance support of the tunnel, prepare conduits with a diameter of 50mm and a wall thickness of 5mm. Each conduit is 4.5m long. quincunx-shaped arrangement, with a longitudinal spacing of 15cm, arranged along the excavation contour line, a circumferential spacing of 35cm, an angle controlled at 10° to 30°, and a lap length of each ring of 1.5m. The tail of each conduit is welded to the corresponding steel arch. The steel arch is the steel arch that forms the primary support.

[0029] (2) Guide the left working area 61 and its initial support. In the operation area on the left side of the upper guide, the reserved ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com