Reinforced type drilling drill bit with gauge protection step

An enhanced and stepped technology, which is applied in the direction of drill bits, drilling equipment, earthwork drilling, etc., can solve problems such as broken teeth, lost teeth, and unsatisfactory slag discharge effect, so as to achieve solid tooth fixation, good slag discharge performance, and good drilling performance. fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

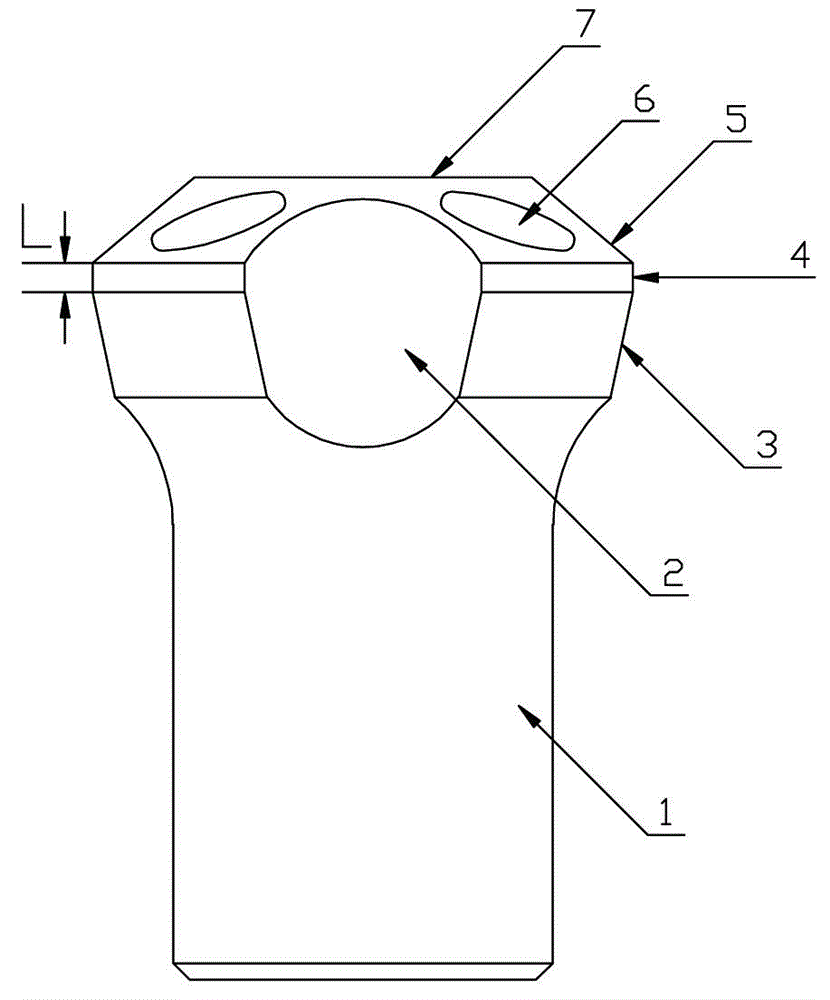

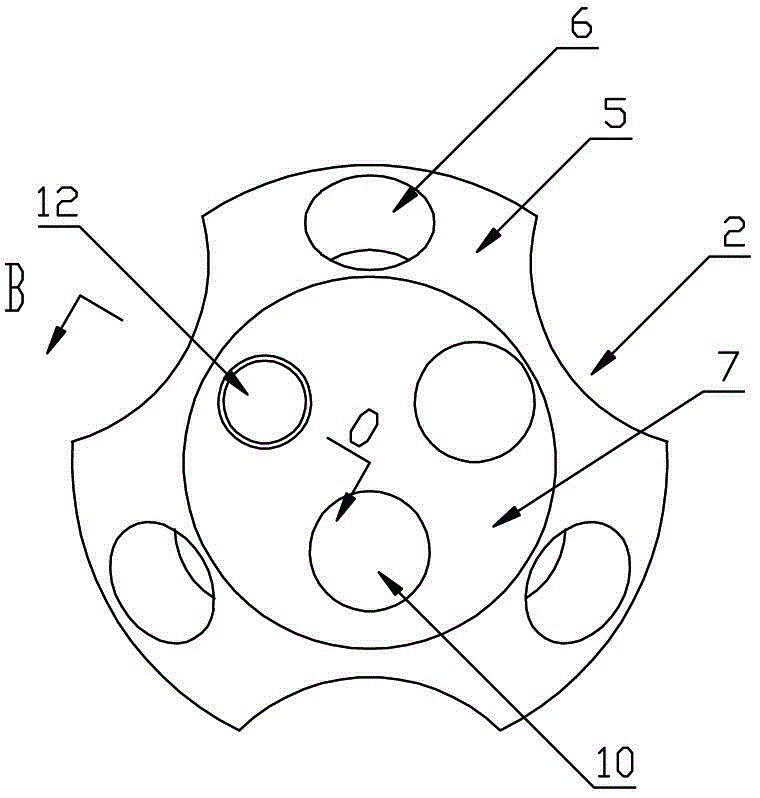

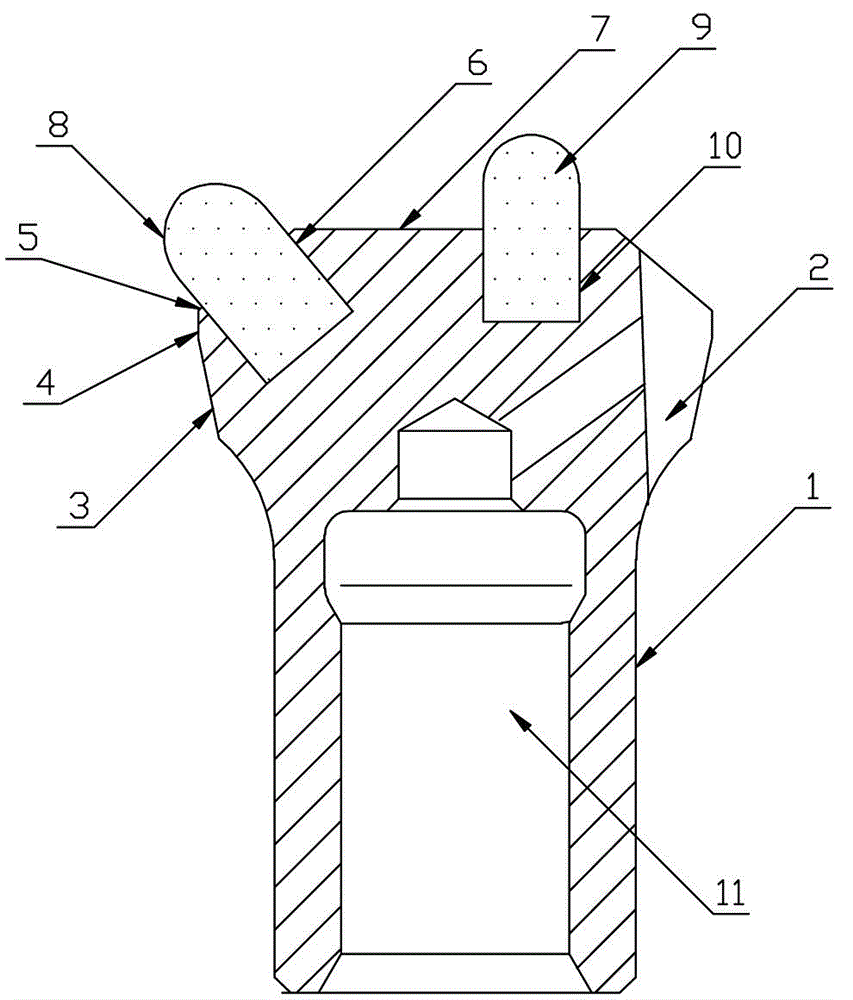

[0019] Example 1: see figure 1 -4, one of the structures of the present invention, it has trouser body 1, is provided with the blind hole 11 that opens downward in trouser body 1, and the lower section of blind hole 11 is threaded hole, and the front end of trouser body 1 is the taper that contracts forward The head is formed with three arc-shaped grooves 2 around the head, and three oblique holes 6 are opened on the conical surface of the head. Alloy teeth 8 are provided with two vertical holes 10 on the end surface of the head, and alloy teeth 9 are embedded in each vertical hole 10, especially: a water hole 12 is drilled on the end surface of the head to communicate with the pants body 1 The blind hole 11; the head and the trouser body 1 are transitionally connected by two sections of structure, the front section is a diameter-gauge step cylindrical section 4 and the head is connected, and the rear section is an inverted cone 3 and the trouser body 1 is connected.

[0020]...

example 2

[0021] Example 2: see Figure 5 —8, the second structure of the present invention, it has trouser body 1, is provided with the blind hole 11 that opens downward in trouser body 1, and the lower section of blind hole 11 is threaded hole, and the front end of trouser body 1 is the taper that contracts forward The head is formed with three arc-shaped grooves 2 around the head, and several oblique holes 6 are opened on the conical surface of the head. Alloy teeth 8, 9 have a number of vertical holes 10 on the end face of the head, each vertical hole 10 is embedded with alloy teeth 8, 9, especially: at least one water hole 12 is drilled on the end face of the head to communicate The blind hole 11 in the trousers body 1; the head and the trousers body 1 are transitionally connected by two sections of structure, the front section is a diameter-gauge step cylindrical section 4 connected to the head, and the rear section is an inverted cone 3 connected to the trousers body 1.

[0022]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com