Elastic support and method for temporarily supporting load by using same

A technology of elastic bearings and butterfly springs, which is applied in the preparation of pillars and building components on site, construction, etc., can solve the problems of complex operation, unrestricted support force, high maintenance cost, etc., and achieve easy operation, simple structure, and no structure. damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

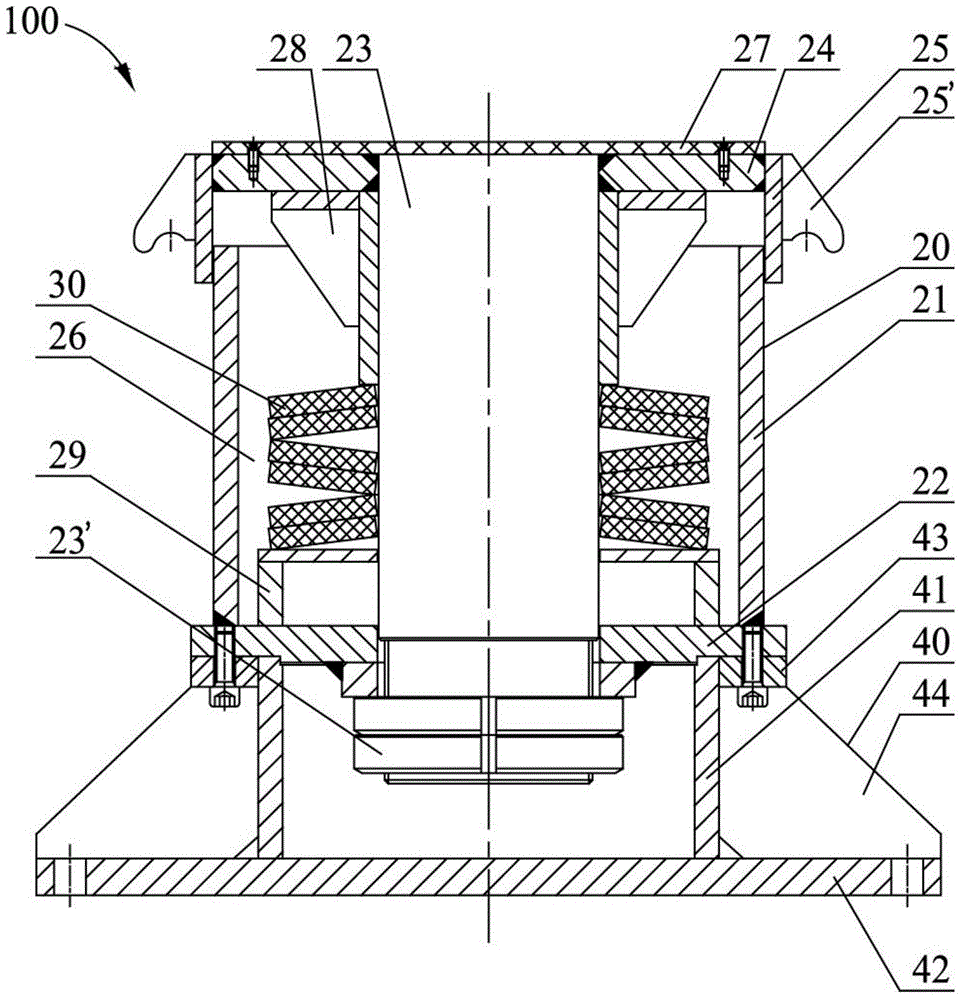

[0025] Example 1: Combining figure 1 Explain that the elastic support 100 of the present invention includes a butterfly spring support 20 and a base 40 arranged up and down and connected by bolts;

[0026] Belleville spring support 20 comprises inner sleeve 21, base plate 22 fixed on the bottom of inner sleeve 21, mandrel 23 vertically arranged in inner sleeve 21, and upper cover plate affixed to the top of mandrel 23, the core The bottom end of the shaft 23 passes through the central hole of the base plate 22 and is locked by a nut. The upper cover plate is formed by connecting the end plate 24 and the outer sleeve 25. The outer sleeve 25 is sleeved outside the inner sleeve 21 and can be moved along the inner sleeve 21. The sleeve 21 slides longitudinally relative to each other, and the upper cover plate, the inner sleeve 21 and the bottom plate 22 jointly form a closed cavity 26, and the butterfly spring group 30 arranged in the cavity 26 is sleeved on the mandrel 23; the bu...

Embodiment 2

[0035] Embodiment two: different from embodiment one, as figure 2 As shown, in the present embodiment, the top of the butterfly spring group 30 is against the end plate 24 of the upper cover plate, that is to say, the adjustment frame 28 is not provided between the end plate 24 and the butterfly spring group 30, and the butterfly spring seat 29 is increased. Height can also achieve a similar effect, which will not be repeated here.

Embodiment 3

[0036] Example Three: Combining figure 1 and figure 2 Illustrate the method for utilizing the elastic bearing 100 of the present invention to temporarily support loads, and the specific steps are as follows:

[0037] S101: First calculate and determine the maximum load and maximum displacement borne by the support node, determine the specification, quantity and superimposition method of the butterfly spring according to the support stiffness, bearing capacity and deformation required by the design, assemble the elastic support 100, and pair the butterfly spring group 30 After pre-compression, tighten the nut 23' at the bottom of the mandrel 23, the purpose of pre-compressing the disc spring group 30 is to allow the disc spring group 30 to enter the working state (10% to 15% of the maximum load must be applied to the disc spring group 30). % of the pressure to make it reach the working state);

[0038] S102: Bolt the elastic support 100 to the support point, so that the load...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com