Normalized design method of production mix proportion and target mix proportion of bituminous mixture

An asphalt mixture and design method technology, which is applied to roads, road repair, roads, etc., can solve the problems affecting the gradation stability of asphalt mixture production mix ratio design mixture, and achieve small deviation, accurate equipment batching, and operation. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings.

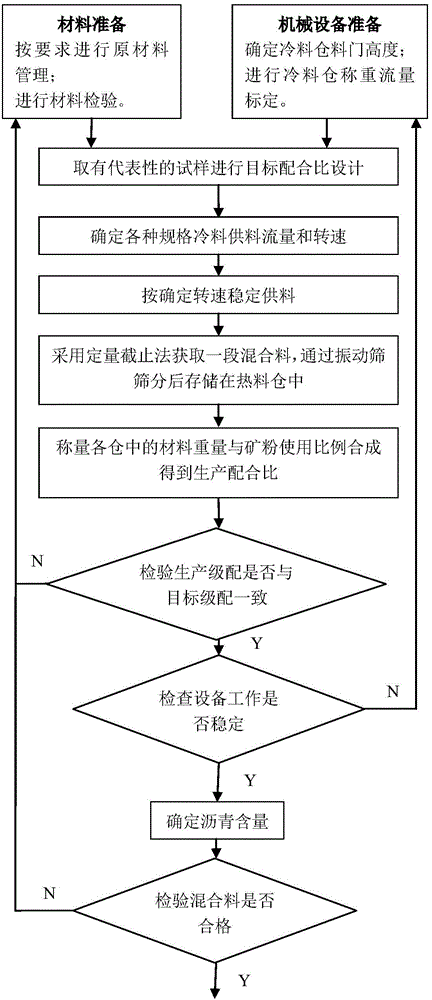

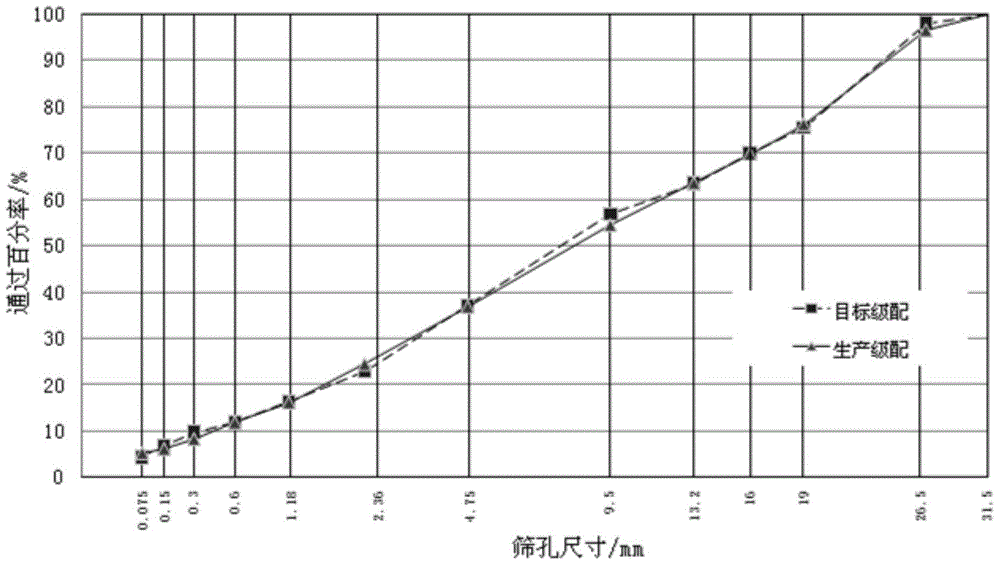

[0025] see figure 1 , the present invention comprises the following steps:

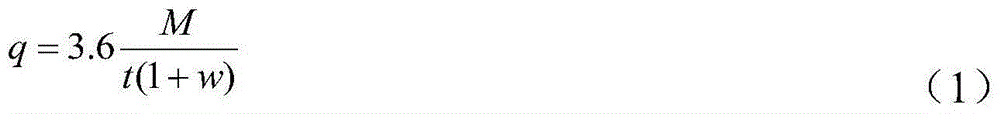

[0026] 1) Calibration of the weighing flow of the cold material bin: use the cold material weighing flow calibration device to calibrate all the cold material bins in turn, and obtain the two-dimensional calibration curves of the speed and flow rate of the feeding belt conveyors of all the cold material bins;

[0027] 2) Normalized design of production mix ratio and target mix ratio:

[0028] 2-1) Sampling is taken from the stockpile, and the target mix ratio design is carried out to obtain the target gradation, target mix ratio and optimal asphalt dosage of the asphalt mixture;

[0029] 2-2) According to the target mixing ratio and the output of the mixing equipment obtained in step 2-1), the feed flow rate of each specification material is obtained;

[0030] 2-3) According to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com