Microalgae breeding device and microalgae breeding method

A breeding method and microalgae technology, applied in the field of microalgae cultivation, can solve the problems of affecting production, net production decline, light energy loss, etc., and achieve the effects of increasing overall production, reducing ventilation energy consumption, and avoiding shear damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

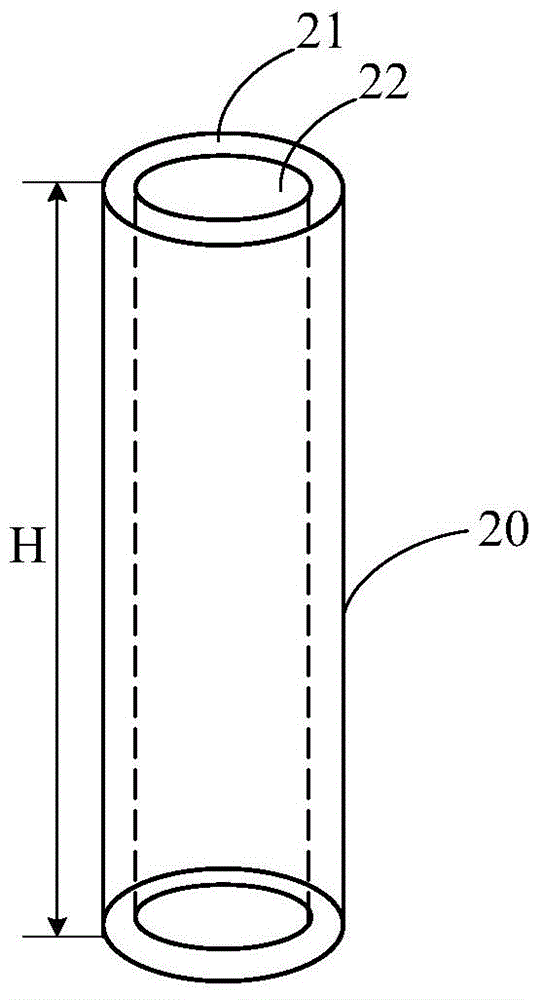

[0104] Microalgae cultivation device: using such as figure 2 The shown height is a double-layer cylindrical nested silicone reactor of H, including two breeding layers of an inner layer and an outer layer, wherein the inner layer optical path (i.e. inner layer diameter) is 3cm, and the outer layer optical path (i.e. Thickness) 1cm.

[0105] Inoculation density: Prepare the medium, concentrate the algae and inoculate it into the reactor. The inoculation density gradually decreases from the outer layer to the inner layer of the reactor, respectively: the inoculation density of the outer layer is 60OD, and the inoculation density of the inner layer is 20OD.

[0106] Aeration form: Aeration is carried out with ring-shaped aeration tubes. The inner and outer layers of the reactor are respectively provided with a set of ring-shaped aeration tubes. During the breeding process, carbon dioxide and air are respectively added to the inner and outer layers of the reactor. Aeration with ...

Embodiment 2

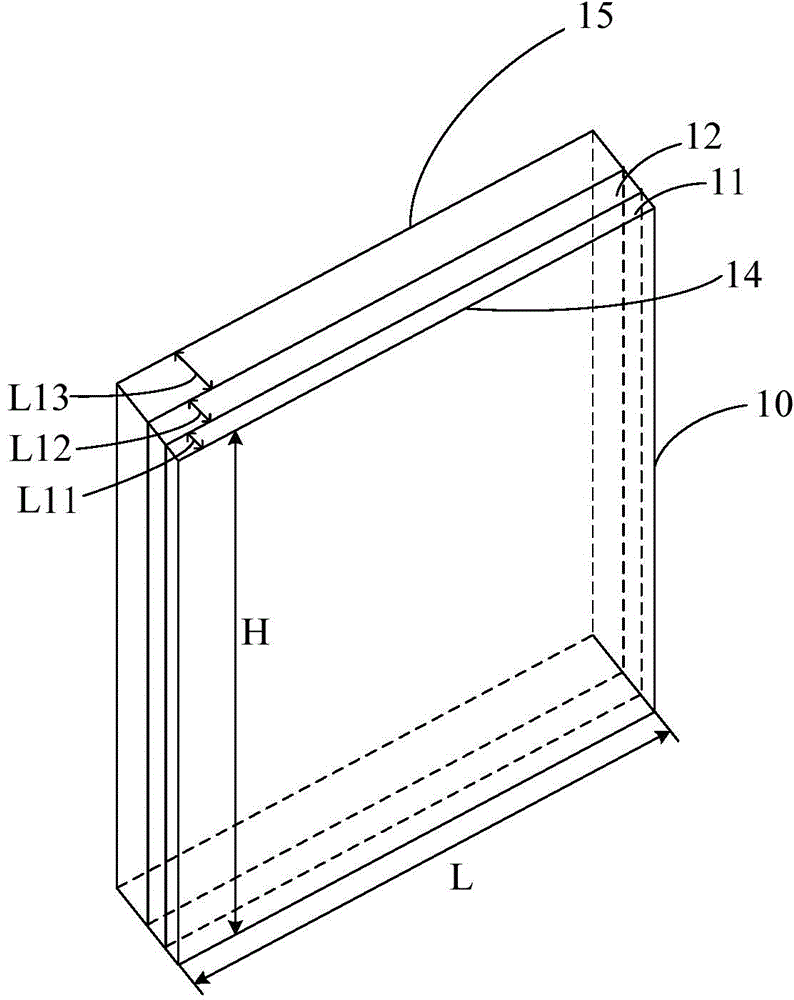

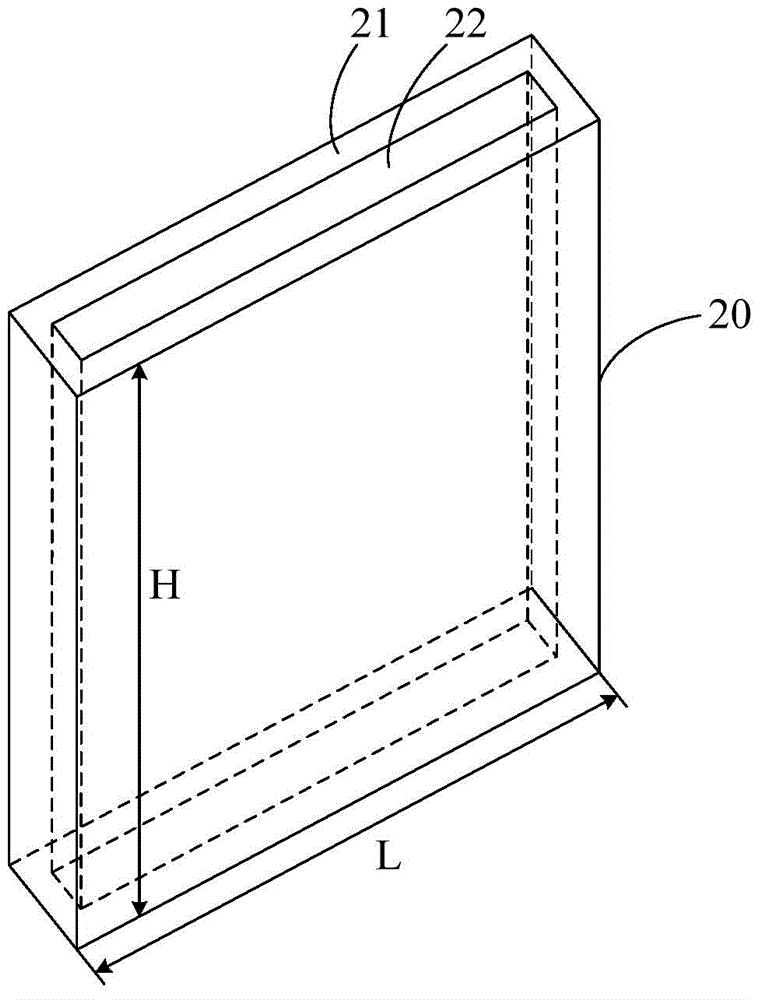

[0126] Microalgae cultivation device: using such as image 3 The shown length is L, height is the double-layer plate type nested silicone reactor of H, comprises inner layer and outer layer two breeding layers, and wherein, inner layer optical distance (that is inner layer thickness) 4cm, outer layer optical path The distance (ie thickness) is 2cm.

[0127] Inoculation density: Prepare the medium, concentrate the algae and inoculate it into the reactor. The inoculation density gradually decreases from the outer layer to the inner layer of the reactor, respectively: the inoculation density of the outer layer is 30OD, and the inoculation density of the inner layer is 15OD.

[0128] Aeration form: Aeration is carried out with ring-shaped aeration tubes. The inner and outer layers of the reactor are respectively provided with a set of ring-shaped aeration tubes. During the breeding process, carbon dioxide and air are respectively added to the inner and outer layers of the reactor....

Embodiment 3

[0134] The microalgae culture is carried out in basically the same manner as in Example 2, the only difference being that the light intensity of each group of light sources in Example 3 is 1000 μmol / m 2 / s.

[0135] Experimental results

[0136] The 5-day average output of embodiment 2 is about 7.5g / day, and the 5-day average output of embodiment 3 is about 8.4g / day, and the 5-day average output of comparative example 2 is about 6.0g / day; Embodiment 2 is relatively Ratio 2 output improves 25%, and embodiment 3 improves 40% compared with comparative example 2 output, simultaneously, embodiment 3 improves 12% compared with embodiment 2 output; But the overall energy consumption of embodiment 2, embodiment 3 is comparative example 29.2% of 2. The energy consumption calculation method is the same as the energy consumption calculation method of the above-mentioned first group of experiments, and will not be repeated here.

[0137] The experimental results are consistent with the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com