Fluorine-containing iodo-hydrocarbon composition and preparation method thereof

A technology of composition and iodocarbon, which is applied in the field of refrigerant composition and its preparation, can solve the problems of poor compatibility, uneven dispersion, and poor flame retardant effect of tetrafluoropropene, achieve good flame retardant effect, and simplify preparation Process, the effect of a wide range of dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

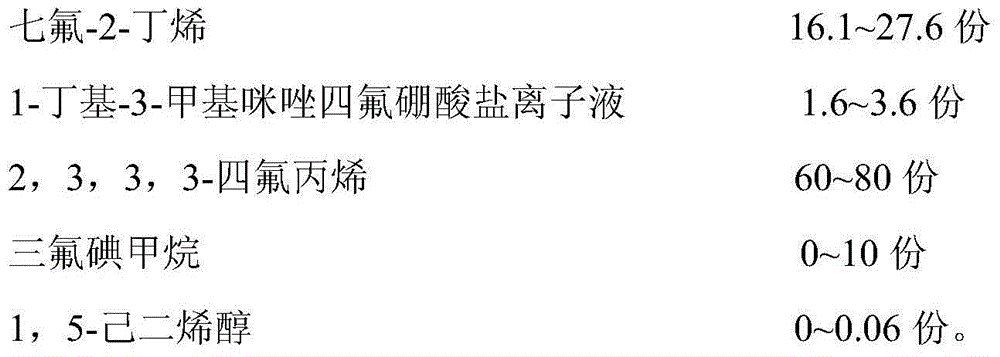

[0030] A kind of fluorine-containing iodohydrocarbon composition, by every part of 1Kg, its raw material formula is as follows:

[0031]

[0032] Its preparation method is as follows:

[0033] The preparation of step (1) ionic liquid flame retardant:

[0034] According to the ratio, add 18.4 parts of heptafluoro-2-butene and 1.6 parts of 1-butyl-3-methylimidazolium tetrafluoroborate ionic liquid into a 200L reactor, and mix them in the liquid state for 15 hours to obtain the ionic liquid flame retardant.

[0035] Step (2) mixing:

[0036] Add the ionic liquid flame retardant prepared in step (1) into a 200L turbulent flow circulating tank, then add 70 parts of 2,3,3,3-tetrafluoropropene (HFO1234yf), 9.97 parts of trifluoroiodomethane, 0.03 parts of 1 , 5-hexadienol, mixed in turbulent flow in liquid state for 8h to obtain the product. The number is WN-1.

Embodiment 2

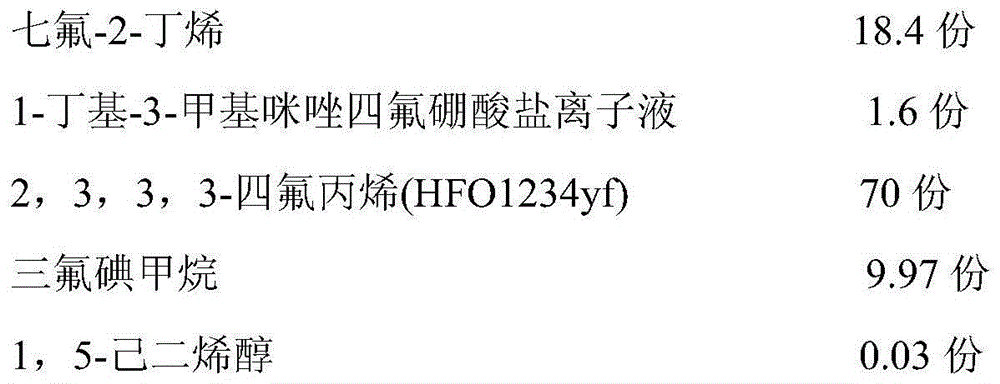

[0038] A kind of fluorine-containing iodohydrocarbon composition, by every part of 1Kg, its raw material formula is as follows:

[0039]

[0040]

[0041] Its preparation method is as follows:

[0042] The preparation of step (1) ionic liquid flame retardant:

[0043] According to the ratio, add 27 parts of heptafluoro-2-butene and 2.99 parts of 1-butyl-3-methylimidazolium tetrafluoroborate ionic liquid into a 200L reactor, and mix them in the liquid state for 10 hours to obtain the ionic liquid flame retardant.

[0044] Step (2) mixing:

[0045] Add the ionic liquid flame retardant prepared in step (1) into a 200L turbulent flow circulating tank, then add 60 parts of 2,3,3,3-tetrafluoropropene (HFO1234yf), 10 parts of trifluoroiodomethane, 0.01 part of 1 , 5-hexadienol, mixed in turbulent flow circulation for 5h in the liquid state to obtain the product, numbered WN-2.

Embodiment 3

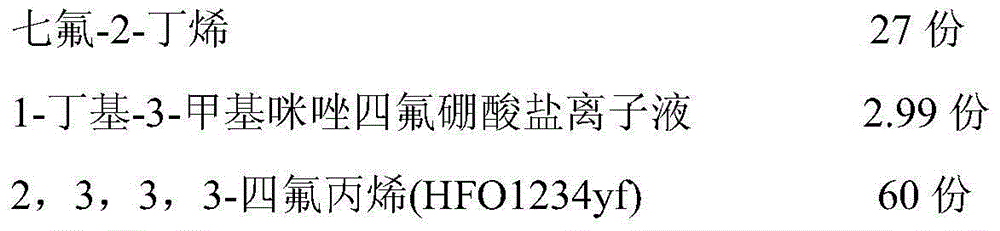

[0047] A kind of fluorine-containing iodohydrocarbon composition, by every part of 1Kg, its raw material formula is as follows:

[0048]

[0049] Its preparation method is as follows:

[0050] The preparation of step (1) ionic liquid flame retardant:

[0051] According to the ratio, add 16.1 parts of heptafluoro-2-butene and 2.85 parts of 1-butyl-3-methylimidazolium tetrafluoroborate ionic liquid into a 200L reactor, and mix them in the liquid state for 20 hours to obtain the ionic liquid flame retardant.

[0052] Step (2) mixing:

[0053] Add the ionic liquid flame retardant prepared in step (1) into a 200L turbulent flow circulating kettle, then add 80 parts of 2,3,3,3-tetrafluoropropene (HFO1234yf), 1 part of trifluoroiodomethane, 0.05 part of 1 , 5-hexadienol, mixed in turbulent flow circulation for 10h in the liquid state to obtain the product, numbered WN-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com