High- fluidity and high-impact ASA material and preparation method thereof

A high-impact, high-flow technology, applied in high-impact ASA materials and their preparation, and high-flow fields, can solve problems such as poor fluidity, difficult filling, and low impact resistance, and achieve high flow, low production costs, and easy preparation The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

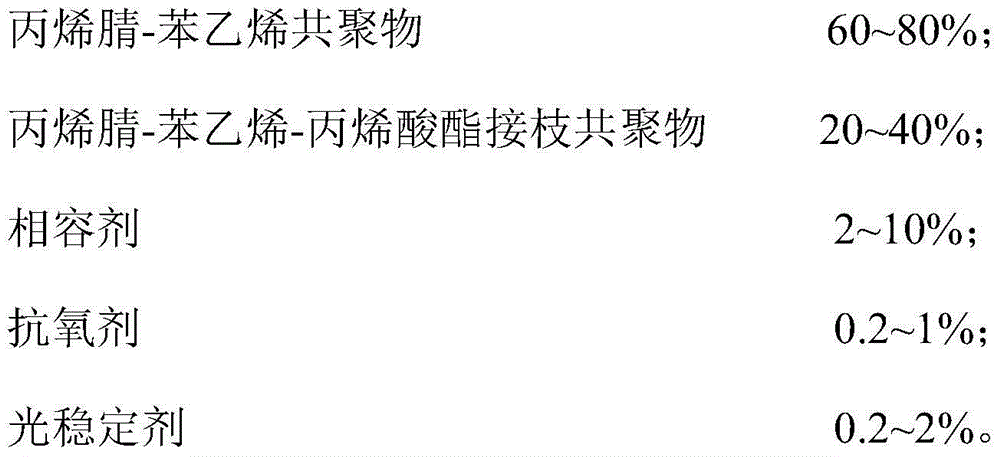

Method used

Image

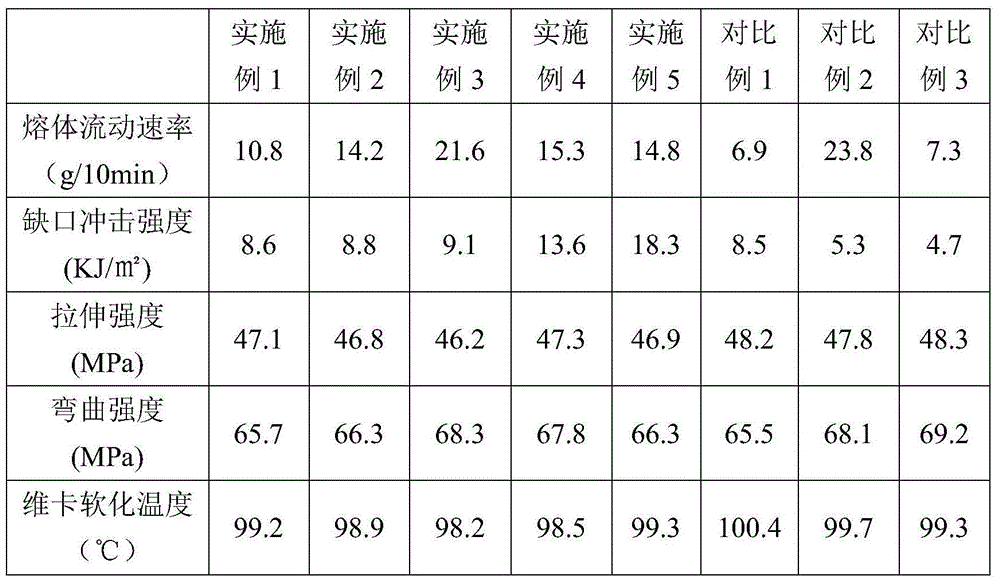

Examples

Embodiment Construction

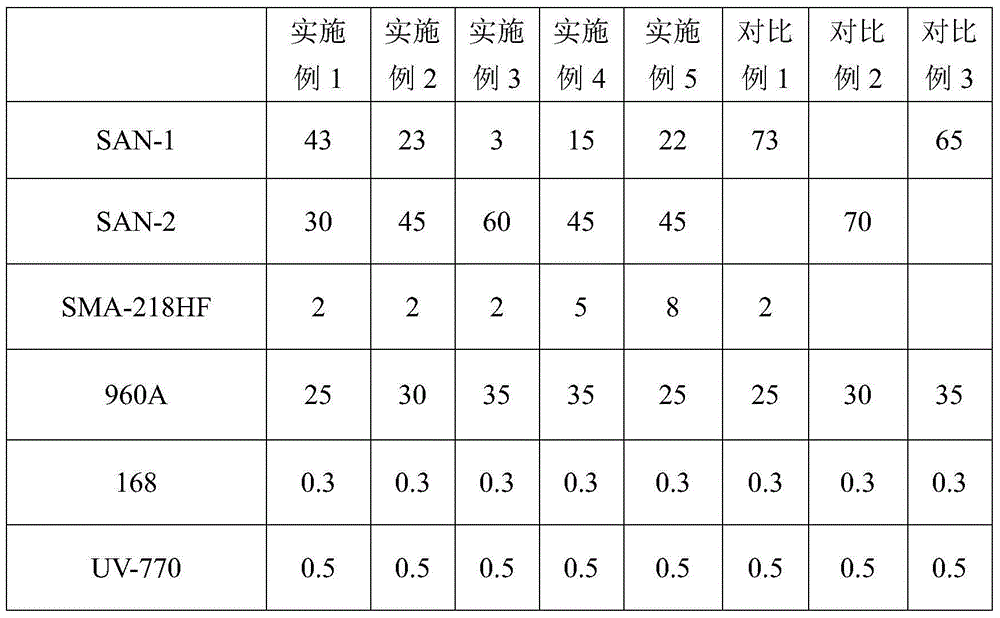

[0020] The present invention will be further described by specific examples below, but the examples are only used to illustrate the present invention and not to limit the present invention.

[0021] Raw materials used in the embodiments of the present invention:

[0022] SAN-1: Acrylonitrile-styrene copolymer, model DN89, with a melt flow rate of 10-20g / 10min (220℃×10kg), Styrolol;

[0023] SAN-2: Acrylonitrile-styrene copolymer, model DN59, with a melt flow rate of 40~60g / 10min (220℃×10kg), Styrolol;

[0024] 960A: Acrylonitrile-styrene-acrylate graft copolymer, glue content 60%, GE company in the United States;

[0025] SMA-218HF: compatibilizer, styrene-maleic anhydride copolymer, Nanjing Yinxin Chemical Co., Ltd.;

[0026] 168: Phosphate ester antioxidant, Ciba, Switzerland;

[0027] UV-770: hindered amine light stabilizer, Ciba, Switzerland.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com