Method for recycling and processing ammonia-nitrogen-containing wastewater in circuit board etching waste liquor recycling industry

A technology for etching waste liquid and ammonia nitrogen waste water, which is applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. Slow growth and other problems, to achieve the effect of enhancing gas-water separation efficiency, prolonging membrane hydrophilization time, and improving membrane hydrophobic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

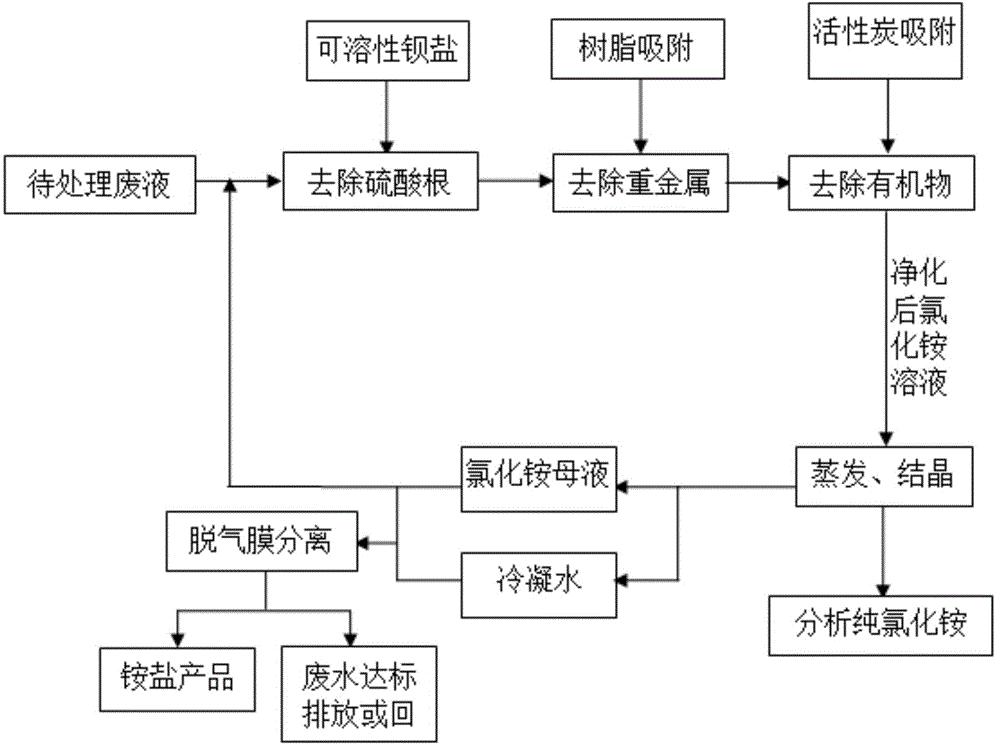

[0038] In this embodiment, a method for resource utilization and treatment of ammonia nitrogen-containing wastewater in the circuit board etching waste liquid recovery industry is carried out as follows:

[0039] 1. Purification of sulfate: Add the waste liquid to be treated containing impurities such as ammonia nitrogen into the reaction tank, and add barium chloride solution into the reaction tank to make SO4 2- with Ba 2+ The molar ratio is 1:2, the temperature is controlled at 90°C, the reaction is 0.5h, and the filter aid FeCl is added 3 The rear inclined plate settles to remove the sediment;

[0040] 2. Purification of heavy metal ions: After adjusting the pH of the supernatant obtained in step 1 to be 4, use macroporous weakly acidic cationic resin D113 to adsorb barium ions and other heavy metal ions, and the flow rate is 6BV / h; after resin adsorption is saturated, use 6mol / L hydrochloric acid regeneration;

[0041] 3. Purification of organic matter: the pH of the f...

Embodiment 2

[0047] In this embodiment, a method for resource utilization and treatment of ammonia nitrogen-containing wastewater in the circuit board etching waste liquid recovery industry is carried out as follows:

[0048] 1. Purification of sulfate: Add the waste liquid to be treated containing impurities such as ammonia nitrogen into the reaction tank, and add barium chloride solution into the reaction tank to make SO4 2- with Ba 2+ The molar ratio is 1:1, the temperature is controlled at 80°C, the reaction is 1h, and the filter aid FeCl is added 3 The rear inclined plate settles to remove the sediment;

[0049] 2. Purification of heavy metal ions: After adjusting the pH of the supernatant obtained in step 1 to 5, use D403 to adsorb barium ions and other heavy metal ions; the commercially available resin is Na-type resin, and 8-10% hydrochloric acid needs to be converted into hydrogen-type resin, and then soaked with 10% ammonia water to convert the resin into ammonium resin; the fl...

Embodiment 3

[0056] In this embodiment, a method for resource utilization and treatment of ammonia nitrogen-containing wastewater in the circuit board etching waste liquid recovery industry is carried out as follows:

[0057] 1. Purification of sulfate: Add the waste liquid to be treated containing impurities such as ammonia nitrogen into the reaction tank, and add barium chloride solution into the reaction tank to make SO4 2- with Ba 2+ The molar ratio is 1:3, the temperature is controlled at 75°C, the reaction is 1.5h, and the filter aid FeCl is added 3 The rear inclined plate settles to remove the sediment;

[0058] 2. Purification of heavy metal ions: After adjusting the pH of the supernatant obtained in step 1 to 7, use weakly acidic macroporous cationic resin LSC-100 to adsorb barium ions and other heavy metal ions; commercially available resins are Na-type resins, and 8- 10% hydrochloric acid is converted into hydrogen-type resin, and then soaked with 10% ammonia water to convert ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com