A device for strengthening ammonia distillation to treat ammonia nitrogen in wastewater

A technology for treating wastewater and distilling ammonia, which is applied in the directions of heating water/sewage treatment, degassed water/sewage treatment, water/sludge/sewage treatment, etc. It can solve the problems of restricting wide application and low treatment accuracy, and achieve operating costs The effect of reducing, improving production efficiency, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Hereinafter, preferred embodiments of the present invention are given in conjunction with the drawings to illustrate the technical solutions of the present invention in detail.

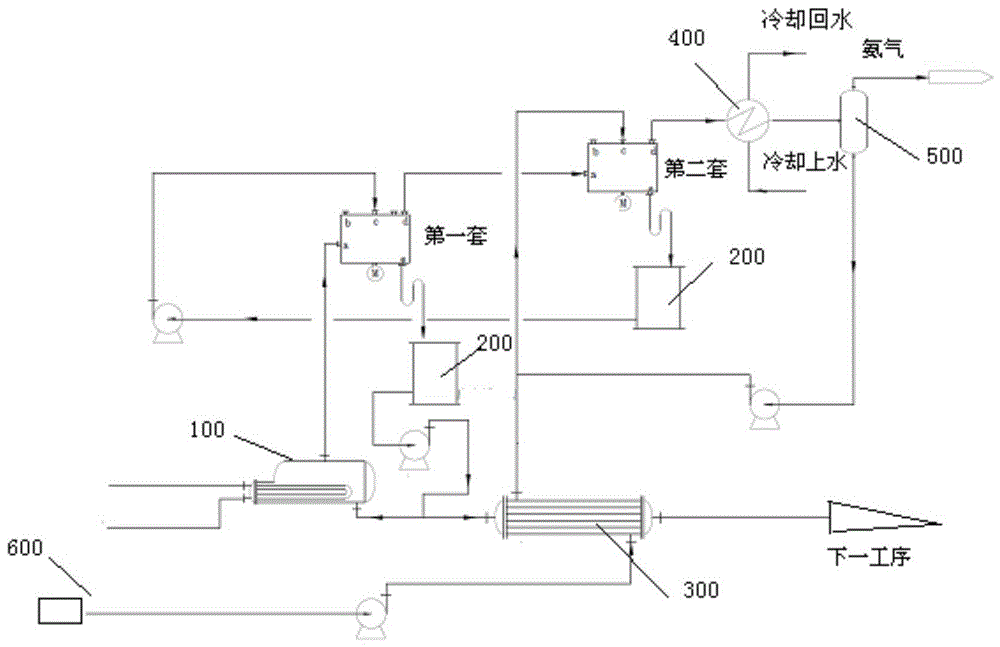

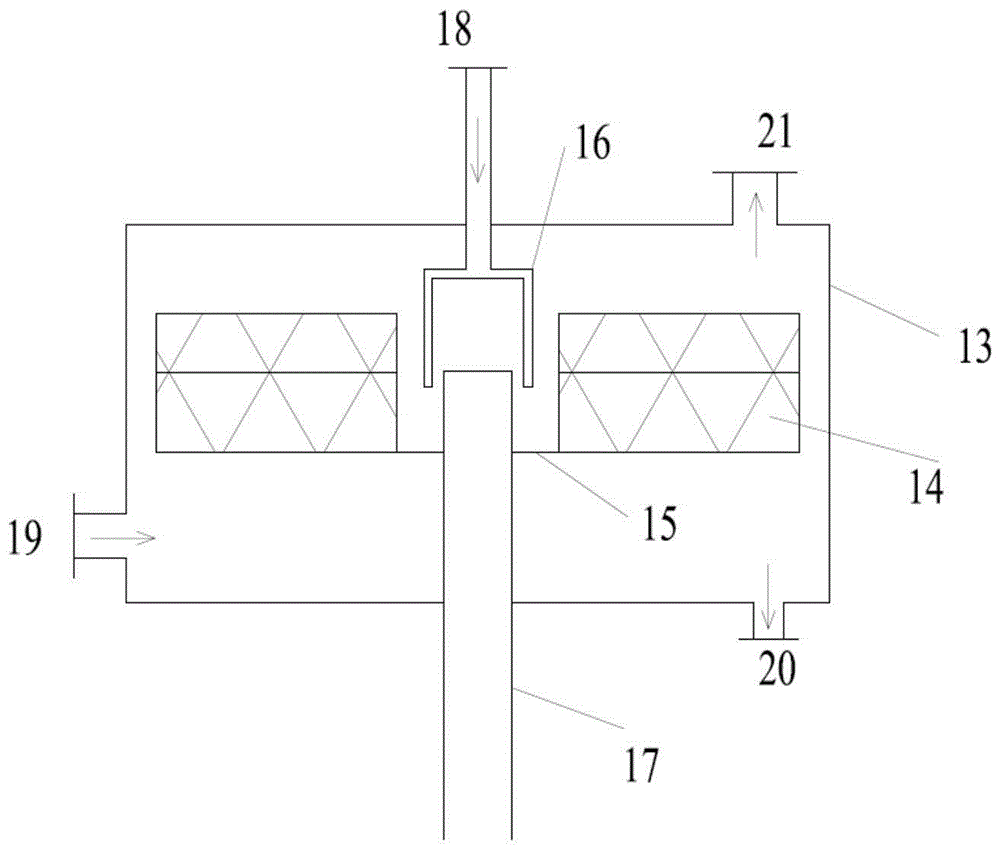

[0020] figure 1 Is a schematic diagram of the overall process of the present invention, figure 2 It is a schematic diagram of the structure of the enhanced ammonia distillation equipment of the present invention. Such as Figure 1-2 As shown, the device for the treatment of ammonia nitrogen in wastewater by enhanced ammonia distillation in the present invention includes: two sets of enhanced ammonia distillation equipment, the enhanced ammonia distillation equipment includes: two sets of enhanced ammonia distillation equipment, the enhanced ammonia distillation equipment includes: a shell 13, A rotating drum 15 is provided in the inner cavity of the shell 13, and a cylindrical rotating packing 14 is arranged in the rotating drum 15. A liquid distributor 16 is arranged in the center of the inner c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com