A composite stirrer with long paddles and short blades

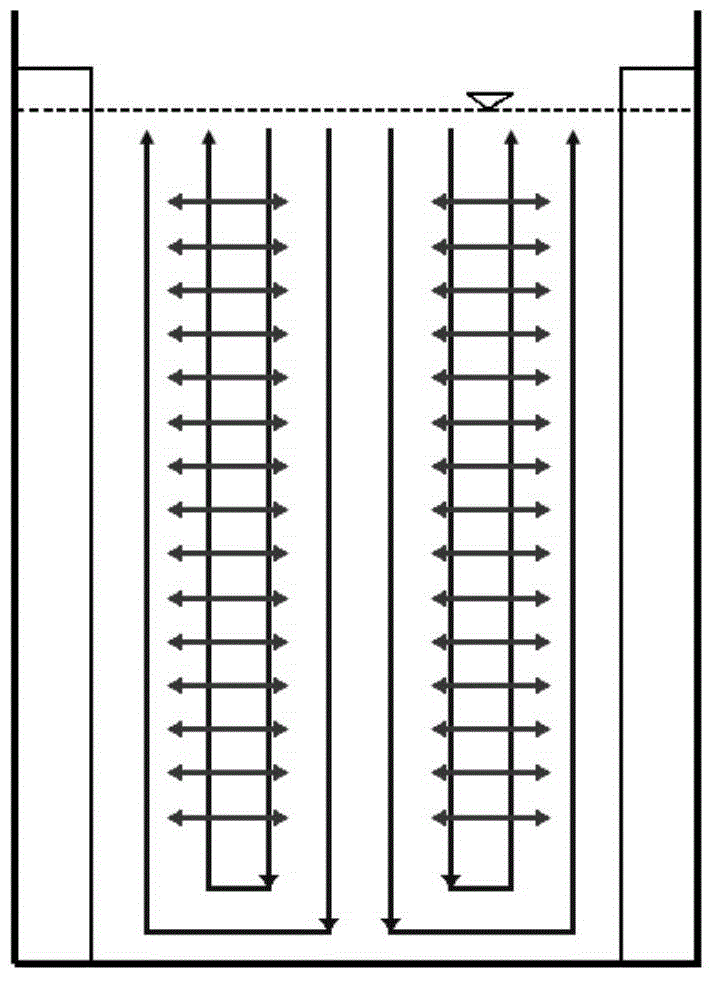

A short blade and agitator technology, which is used in mixers, mixers, mixing methods and other directions with a rotating stirring device, can solve the problems of insufficient gas absorption and uneven gas distribution, and achieve simple structure and improved gas-liquid transmission. Quality efficiency, the effect of a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

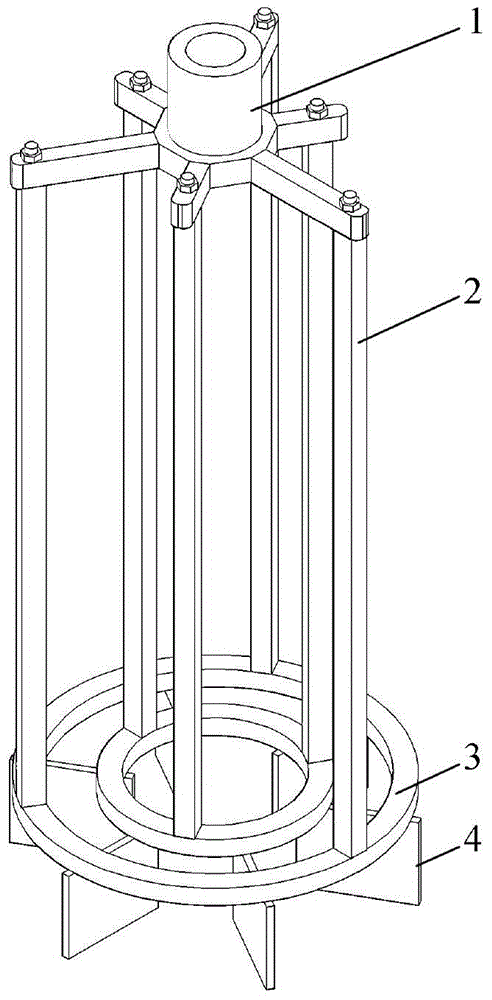

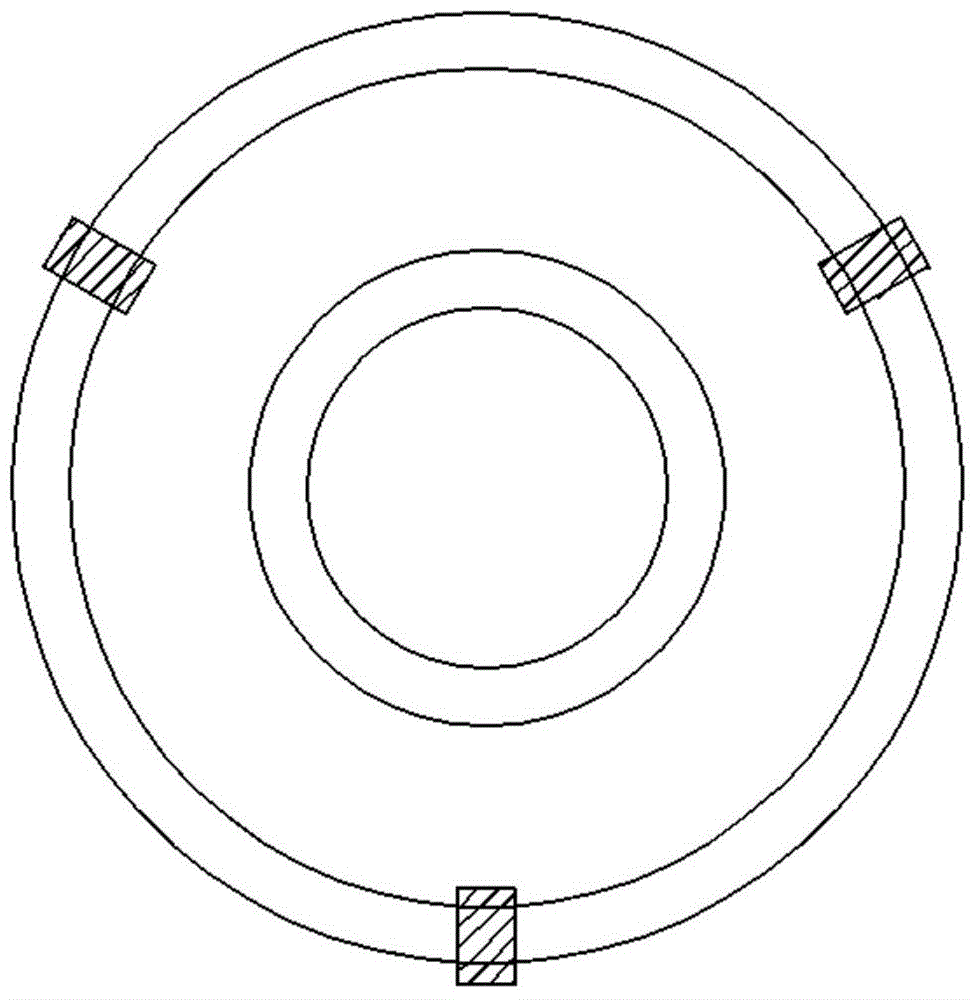

[0042] Compound agitator with long paddles and short blades, see figure 2 , including fixed plate 1, long paddle 2, connecting plate 3 and short blade 4, the top of long paddle 2 is fixed on the bottom of fixed plate 1 through nuts, the bottom end is fixed on the top of connecting plate 3, and short blade 4 is fixed on the bottom of connecting plate 3 bottom. The connecting disc 3 is a group of concentric rings, and the group of rings and the short blades 4 are fixed to each other by welding or other methods.

[0043] In this embodiment, the number of long paddles 2 is three, and the long paddles 2 are cuboids whose horizontal section is a rectangle of 16×8mm, the angle between the long side of the rectangle and the radial direction is β=0°, and the long paddles 2 are evenly distributed in On the outermost ring of connection plate 3, see image 3 The height of the long paddle is 850mm; the short blade 4 is a flat plate, its length and height are 80mm and 60mm respectively, an...

Embodiment 2

[0049] Adopt the compound agitator with long paddle and short blade of the same structure and size as Example 1, only adjust the angle β between the long side of the rectangle and the radial direction by 45°, as Figure 5 As shown, the rest of the operating conditions remained unchanged.

[0050] When the stirring speed is N=200rpm, the above-mentioned long and short paddle composite stirrer is used:

[0051] When H / D T =1, the power consumption per unit volume P / V=3.3kW / m 3 , volumetric mass transfer coefficient k L a=0.132s -1 ;

[0052] When H / D T =2, power consumption per unit volume P / V=4.8kW / m 3 , volumetric mass transfer coefficient k L a=0.120s -1 .

[0053] The above results show that whether it is clockwise or counterclockwise, the power consumption per unit volume P / V is slightly smaller than that of the mass transfer coefficient k under the same conditions. L The a value is also slightly smaller than the measured value of the long paddle and short blade c...

Embodiment 3

[0055] Adopt the long paddle short blade composite agitator of the same structure and size as embodiment 1, only the long paddle 3 is evenly distributed on the inner ring of the connection plate, as Figure 6 Shown, all the other operating conditions also keep consistent with embodiment 1.

[0056] When the stirring speed is N=200rpm, the above-mentioned long and short paddle composite stirrer is used:

[0057] When H / D T =1, the power consumption per unit volume is 3.8kW / m 3 , volumetric mass transfer coefficient 0.121s -1 ;

[0058] When H / D T =2, the power consumption per unit volume is 5.6kW / m 3 , volumetric mass transfer coefficient 0.086s -1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com