A kind of high-efficiency catalytic rectification column inner catalyst bundle packing and preparation method thereof

A catalytic rectification column and catalyst package technology are applied in the field of catalyst bundle packing in a high-efficiency catalytic rectification column and its preparation field, which can solve the problems of small diameter, increased pressure drop in the column, easy liquid flooding and the like, and achieve diffusion The effect of low resistance, easy processing and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings.

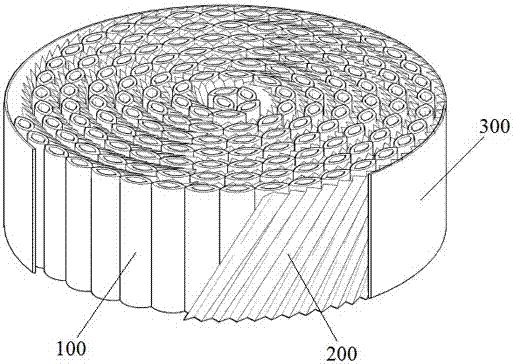

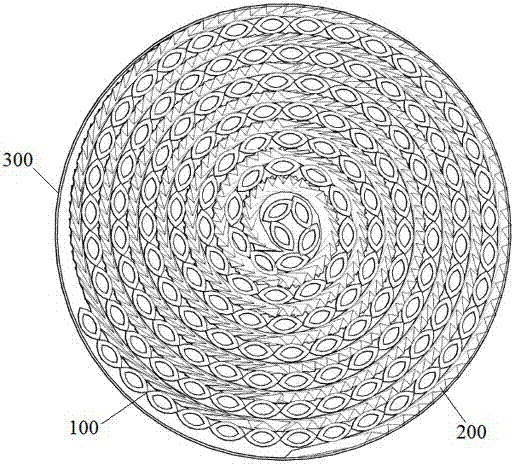

[0028] Such as Figure 1~3 As shown, a catalyst bundle packing in a high-efficiency catalytic rectification column includes a catalyst chain 100 and a regular corrugated packing sheet 200, and the catalyst chain 100 is formed by connecting a plurality of catalyst packs 110 with a hollow structure. The catalyst package 110 is filled with solid catalyst particles 111 , and the catalyst package chain 100 and the regular corrugated packing sheet 200 are closely attached and coiled and then fixed and formed by the clamping sheet 300 .

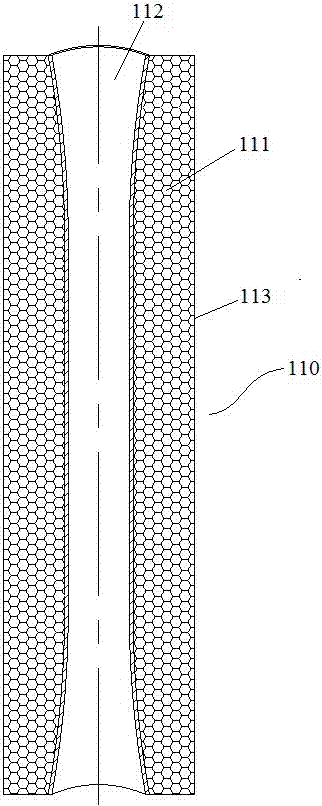

[0029] In the embodiment of the present invention, the hollow structure is located at the center of the catalyst package 110 , the hollow structure is provided with a support 112 , and the solid catalyst particles 111 surround the ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com