Collaborative process for reforming biomass chemical chains to produce hydrogen and inhibit production of tar

A technology for reforming hydrogen and biomass, applied in the direction of inorganic chemistry, chemical instruments and methods, hydrogen, etc., can solve the problems of low gasification efficiency, unpublished operating process parameters, low hydrogen concentration, etc., and reduce tar production , low tar content and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

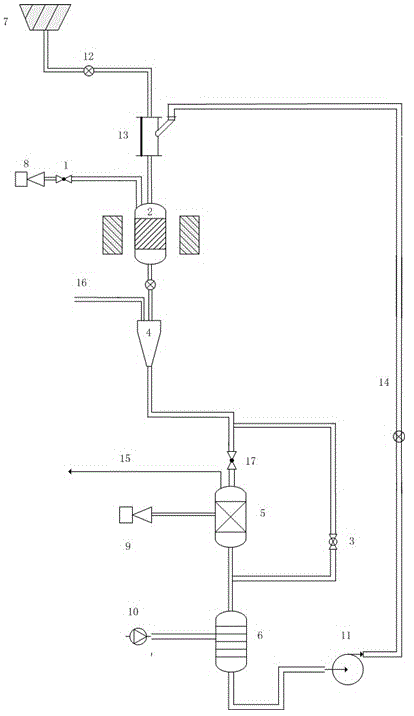

[0029] The present invention will be described in further detail below in conjunction with specific embodiments and accompanying drawings.

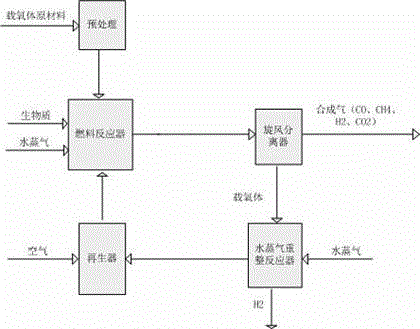

[0030] Such as figure 1 As shown, a biomass chemical chain reforming hydrogen production and tar removal combined process equipment is mainly composed of a catalytic cracking reactor 2, a cyclone separator 4, a hydrogen production reactor 5 and an oxygen carrier regeneration reactor 6.

[0031] The raw material in the raw material hopper is mixed with the iron-based composite oxygen carrier transported by the lift pump in the mixer 13, and then enters the catalytic cracking reactor 2, which has a shut-off valve under the catalytic cracking reactor 2. The lower outlet of the cyclone separator 4 is connected to the hydrogen production reactor 5 , and the synthesis gas generated in the catalytic cracking reactor 2 is discharged through the gas path 16 . The iron-based composite oxygen carrier separated by the cyclone separator reacts with wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com