Car loading equipment capable of realizing automatic box loading and stacking

An automatic boxing and palletizing technology, which is applied in the directions of transportation, packaging, loading/unloading, etc., can solve the problems of high labor intensity, many loading personnel, damaged bags, etc., achieve a high degree of automation, and improve the efficiency of loading and palletizing , Improve the effect of logistics speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

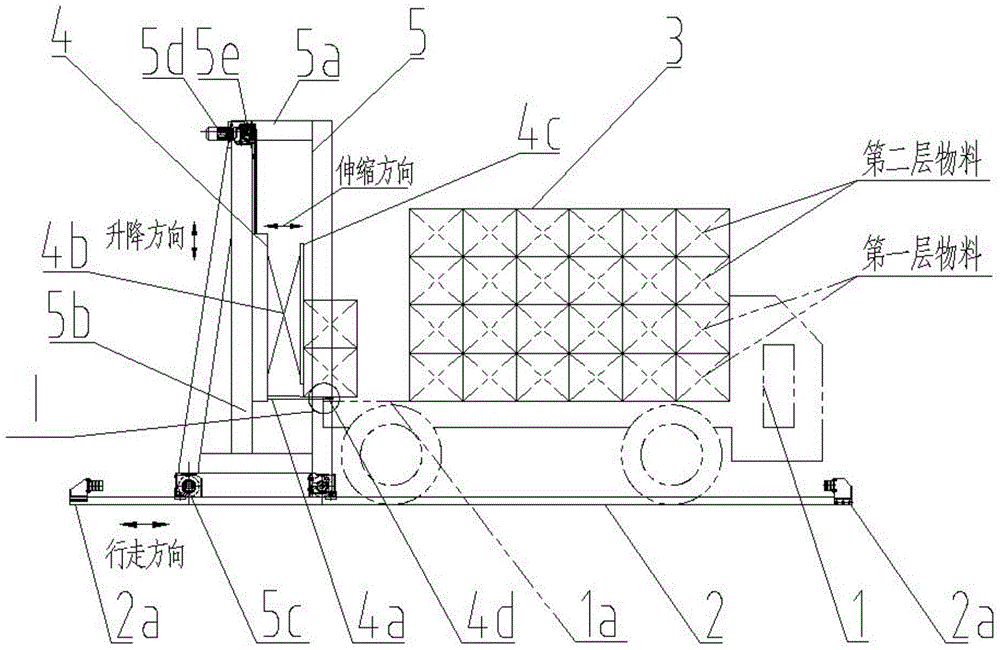

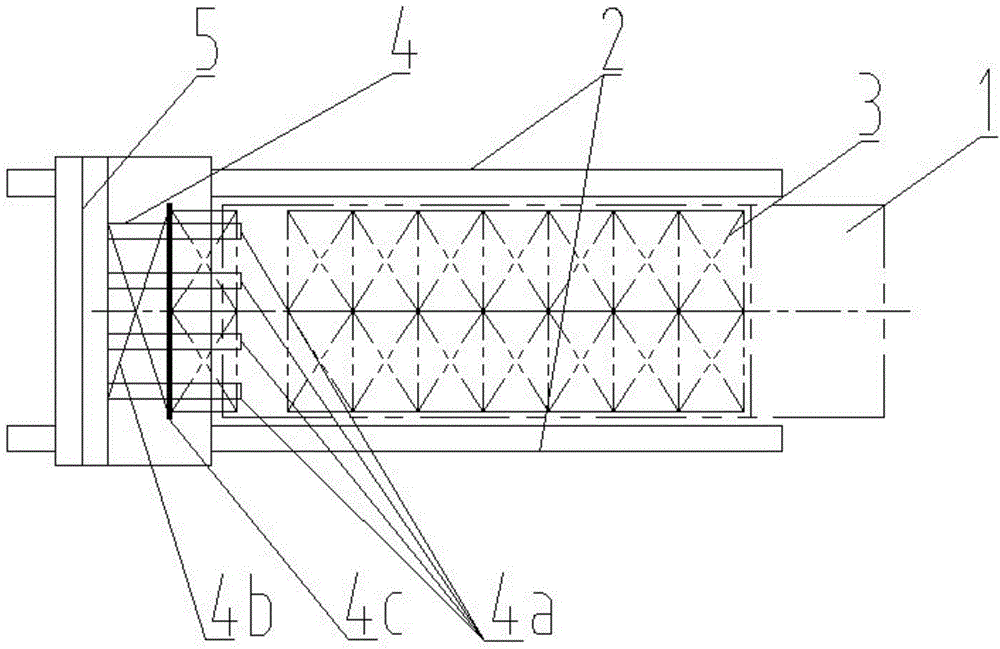

[0028] Such as Figure 1 to Figure 5 As shown, a loading device capable of automatic packing and palletizing includes a flatbed trailer 1 for receiving goods from outside, two rails 2 placed on the left and right sides of the flatbed trailer 1, one placed on the rails 2 and capable of The gantry transfer device 5 and control system that walks along it; the guardrails on three sides of the cargo flat car 1 that receives goods from the outside can be removed, and its working surface is a flat car 1a; anti-collision devices are installed at the ends of the two sides of the track 2 2a; the gantry transfer device 5 is placed on the track 2, and can move left and right along the track 2; the gantry transfer device 5 includes a main body gantry frame 5a, columns 5b on the left and right sides, a traveling mechanism 5c, and a lifting mechanism 5d , l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com