Length calibration device and calibration method for 7a60 aluminum alloy tensile specimen at room temperature

A technology for tensile samples and calibration devices, applied in the preparation of test samples, printing, typewriters, etc., can solve the problems of cumbersome operation, easy wear, poor precision, etc., to avoid poor controllability, improve marking efficiency, The effect of increasing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

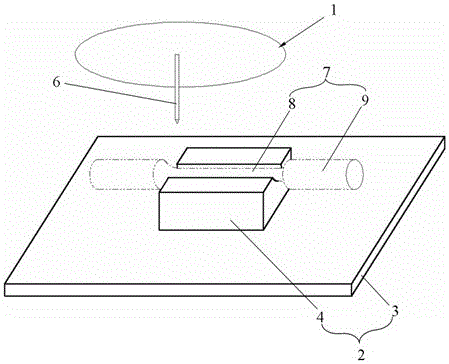

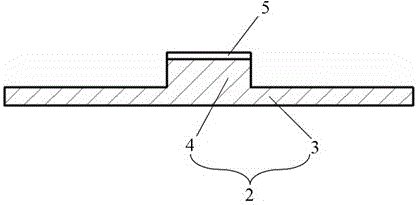

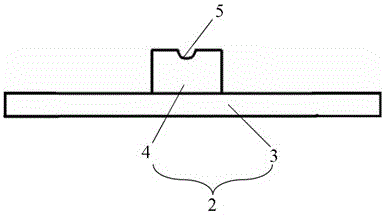

[0024] The high-efficiency gauge length calibration device and calibration method of the 7A60 ultra-high-strength aluminum alloy room temperature tensile sample of the present invention will be described in detail below in conjunction with the accompanying drawings and examples:

[0025] like Figure 1~3 As shown, a high-efficiency gauge length calibration device for a 7A60 ultra-high-strength aluminum alloy tensile sample at room temperature includes a laser marking machine 1 and a fixing seat 2 arranged directly below the laser marking machine 1, and the fixing seat 2 is formed by the base 3 and a positioning block 4 installed on the top surface of the base 3, and a groove 5 is formed on the top surface of the positioning block 4.

[0026] The diameter of the groove 5 is larger than the diameter of the working section 8 of the sample 7 .

[0027] The length of the groove 5 is smaller than the length of the working section 8 of the sample 7 .

[0028] A method for calibrati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com