Base material fitting method and base material fitting method

A bonding device and base material technology, applied in lamination devices, chemical instruments and methods, electronic equipment, etc., can solve the problems of time-consuming, economic cost, low production capacity, etc., to improve efficiency, improve bonding accuracy, save The effect of time and economic cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] In order to make the above features and beneficial effects of the present invention more obvious and understandable, the present invention will be described in detail below in conjunction with the embodiments. It should be noted that the terms "first", "second", and "third" used herein ", "vertical", "horizontal", "above", "below" and similar expressions are for illustrative purposes only and do not represent the only implementation.

[0057] In order to illustrate the technical solutions of the present invention, specific examples are used below to illustrate.

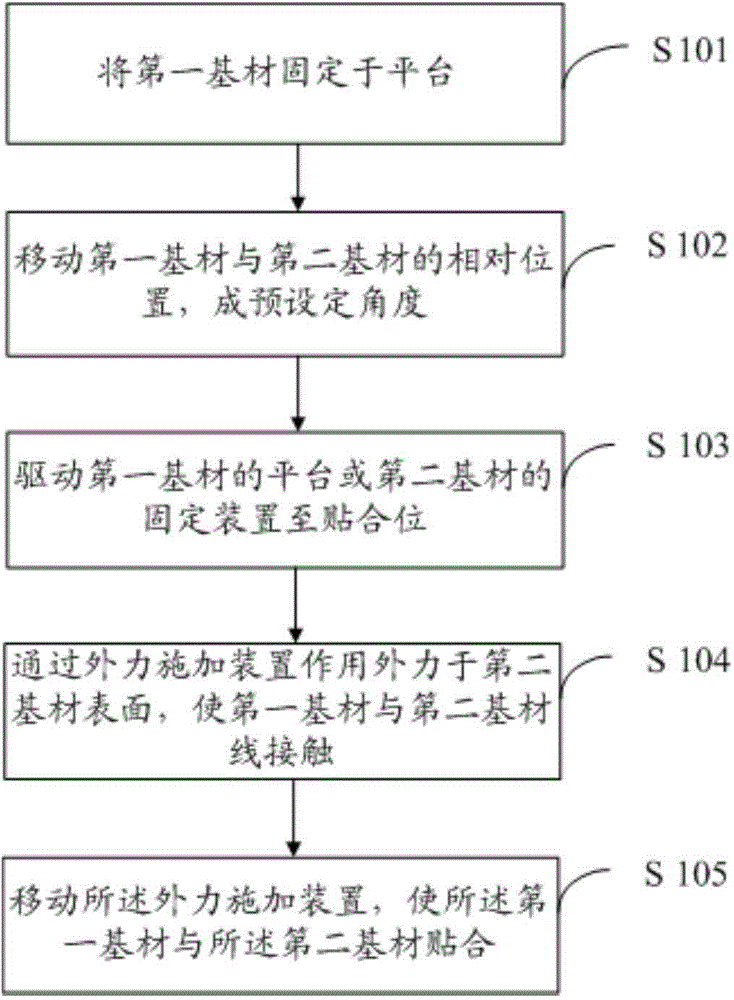

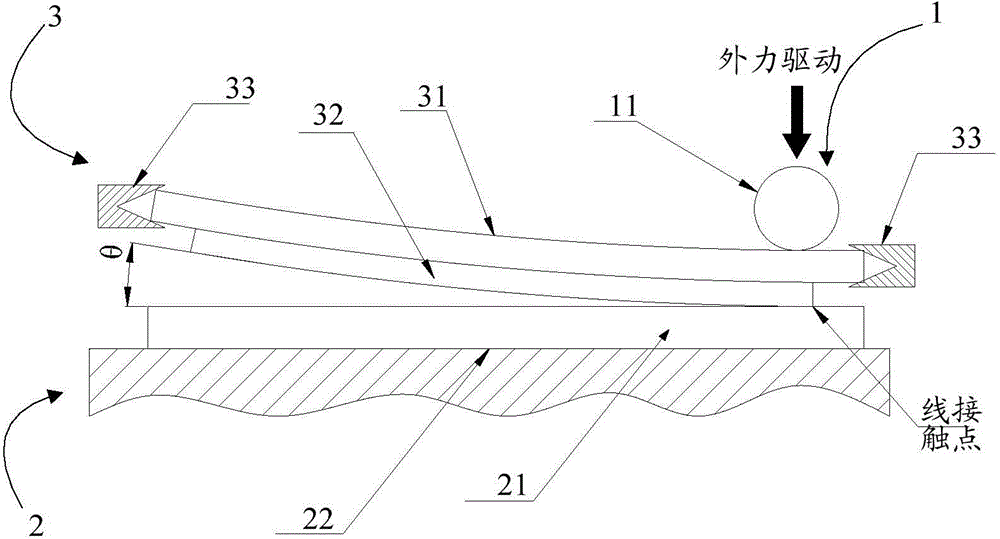

[0058] figure 1 It shows the implementation flow of the substrate bonding method provided by the embodiment of the present invention. The following implementation steps are all implemented in the atmospheric environment, and the specific details are as follows:

[0059] In step S101, fixing the first base material on the platform;

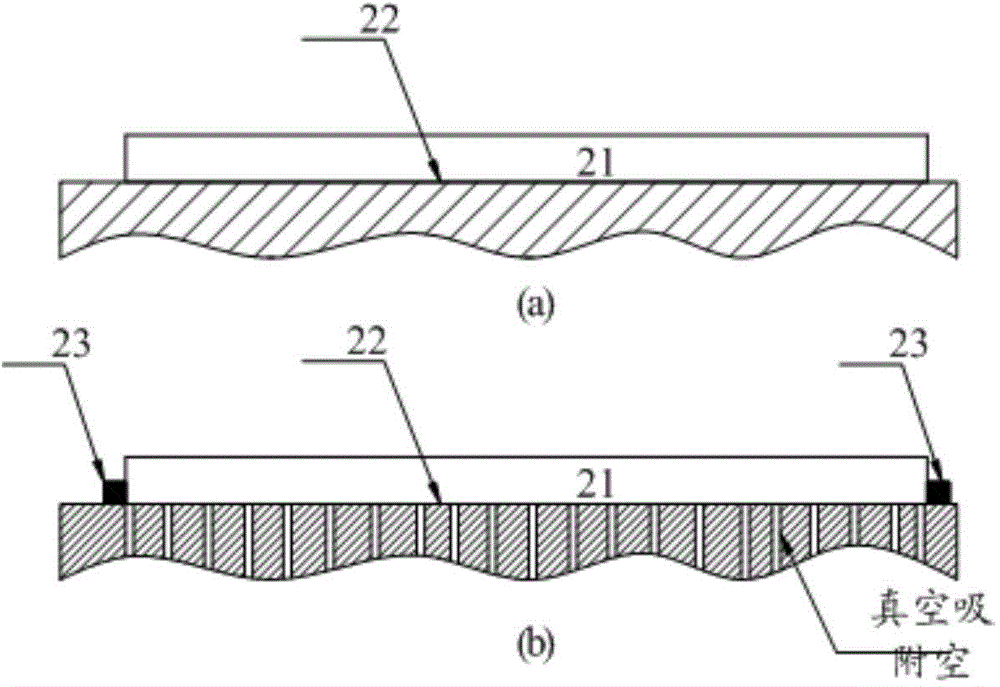

[0060] The first substrate is placed on the platform and fixed by vacuum adso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com