Air pressure large force suction cup

A suction cup and air pressure technology, applied in the field of parts clamping, can solve the problems of unfavorable use of workpieces, easy magnetization of workpieces, high labor intensity, etc., and achieve the effects of reducing labor intensity, uniform pressing force, and convenient clamping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

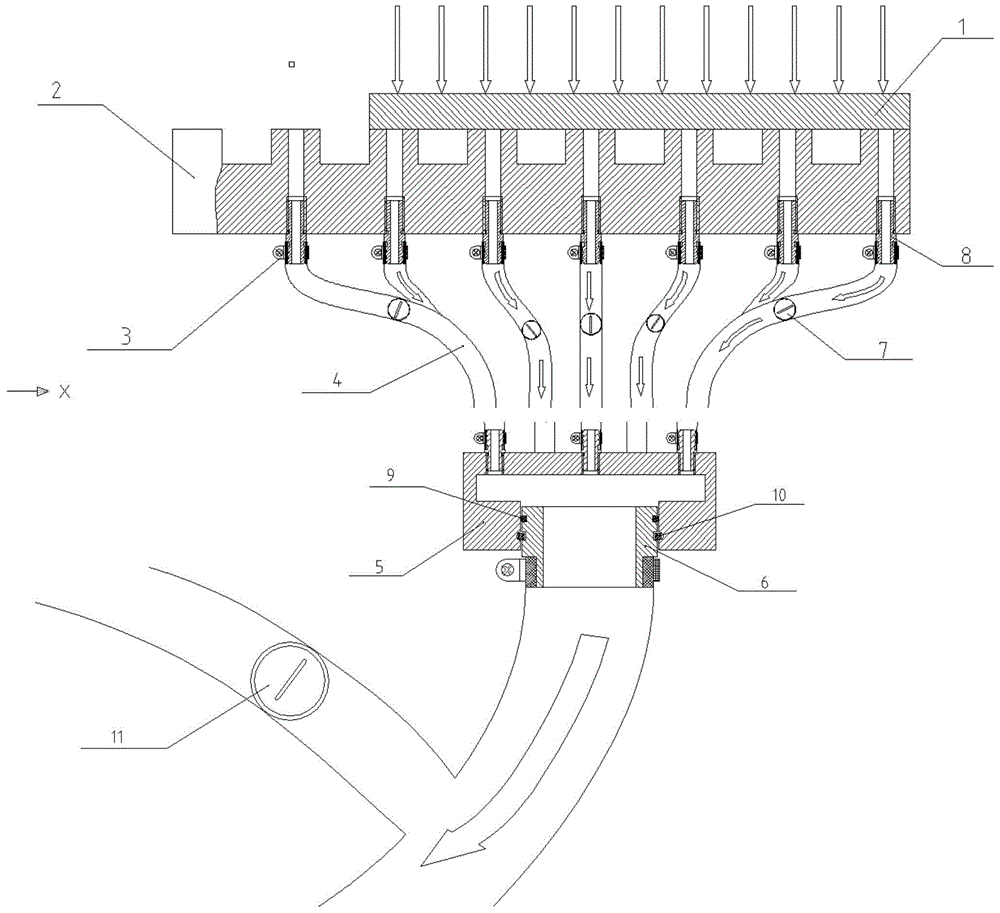

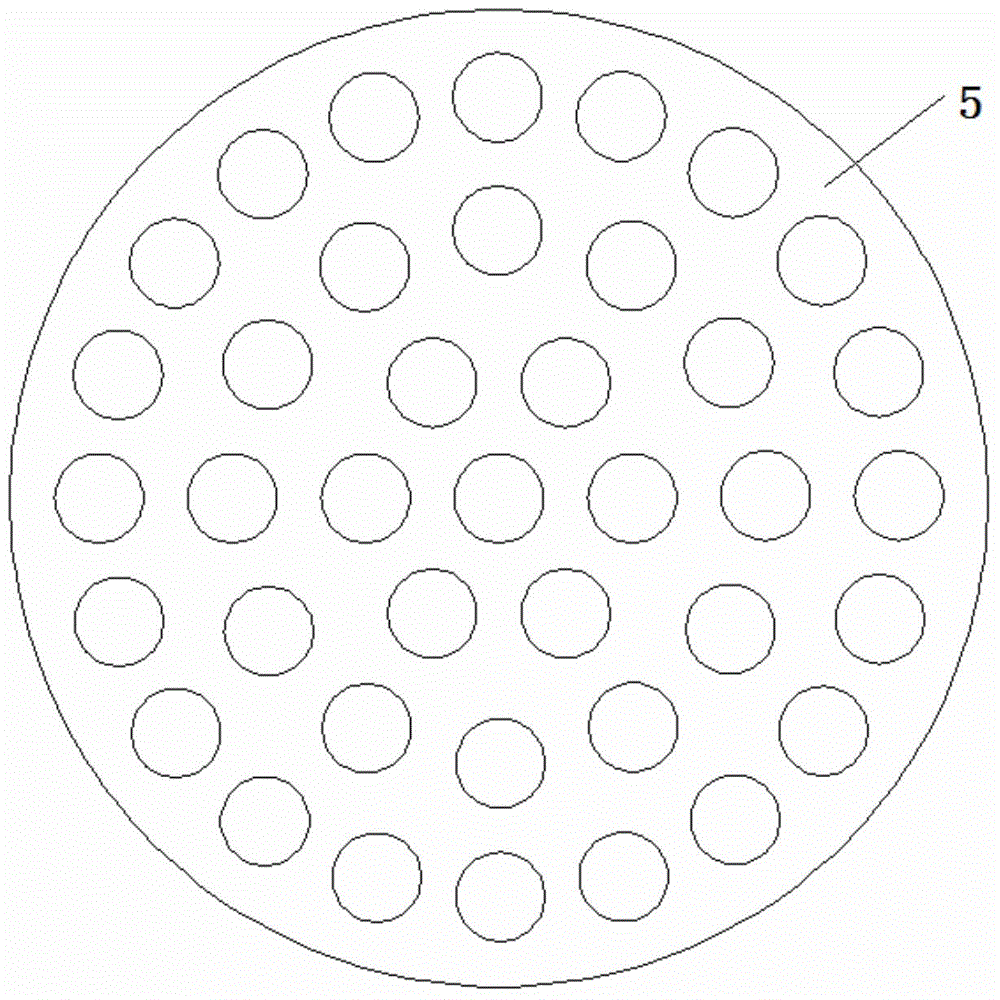

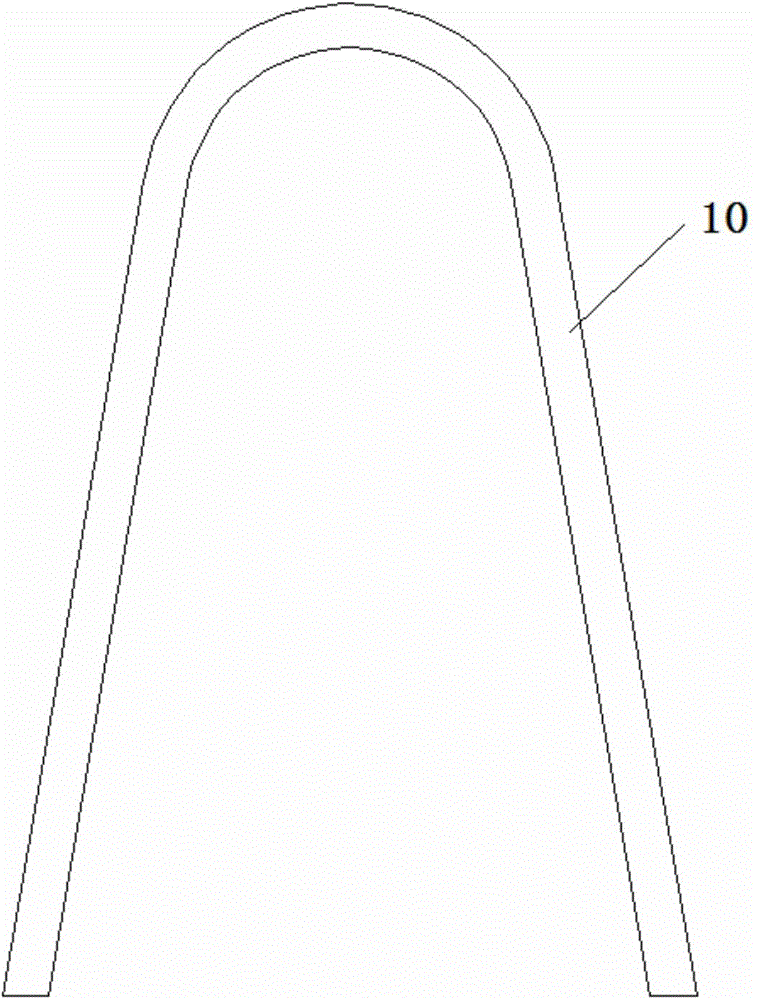

[0017] Such as figure 1 As shown, a pneumatic suction cup of the present invention includes a clamping platform 2, on which a plurality of identical square platforms are milled, each platform is punched with a through hole, and the bottom of the through hole is threaded , a plurality of high-pressure air pipes 4 are connected to the through-holes through the air pipe joints 8 inserted into the bottom of the through-holes. The high-pressure air pipes 4 are equipped with air valves 7 and also include round cake joints 5. The round cake joints 5 are round cake-shaped cavity structures, on which The surface is evenly distributed with multiple identical screw holes, and the other ends of multiple high-pressure air pipes 4 are connected to the round cake joint 5 through the air pipe joint 8 inserted into the screw hole, and the lower openin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com