Self-adaption tension control device and method of electrode wires of linear cutting machine

A wire cutting machine tool and tension control technology, which is applied in the direction of electrode manufacturing, manufacturing tools, electric processing equipment, etc., can solve the problems of inaccurate detection and control of electrode wire tension in the processing section, and affect the processing quality, so as to improve the processing quality and intelligent high level effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in further detail below in conjunction with the accompanying drawings.

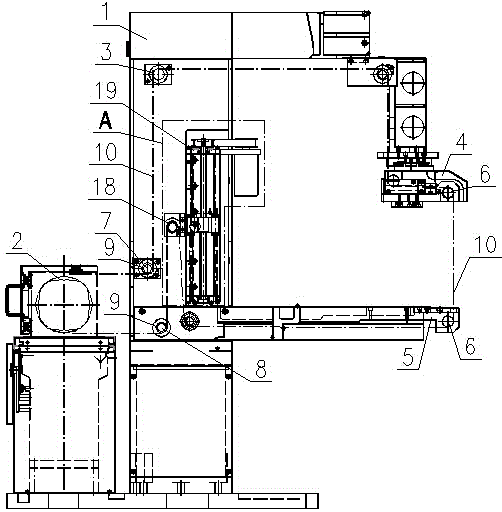

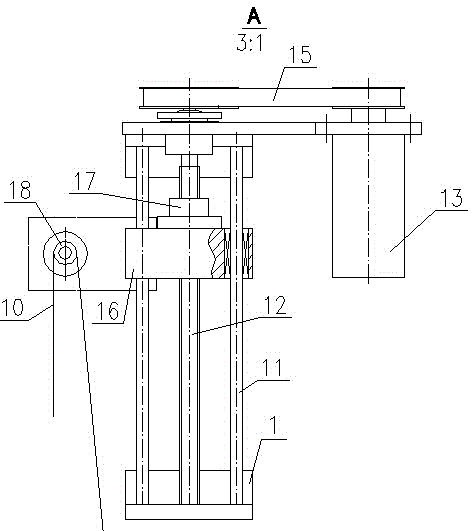

[0012] like figure 1 , figure 2 As shown, the self-adaptive tension control device of the electrode wire of the wire cutting machine tool includes a frame 1, a wire storage tube 2 arranged on the frame 1, four transition reversing wheels 3, an upper head 4 and a lower head 5 , the upper machine head 4 and the lower machine head 5 are all provided with main guide wheels 6, and the frame 1 between the upper machine head 4 and the wire storage drum 2 and the lower machine head 5 and the wire storage drum 2 are respectively provided with Axial tension sensor 7 or 8, each axial tension sensor 7 or 8 is equipped with a tension detection wheel 9 through a bearing, which is wound around the wire storage drum 2, all transition reversing wheels 3, tension detection wheel 9 and the main guide wheel The electrode wire 10 on 6 forms a wire-traveling loop, and the elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com