Electrostatic powder spraying trolley for multi-branch-path electrostatic external arrangement

An electrostatic powder and trolley technology, which is applied to electrostatic spray devices, spray discharge devices, spray devices, etc., can solve the problem that it cannot be installed in a separate powder electrostatic sprayer, cannot be protected by a protective cover and dustproof, and cables are difficult to arrange, etc. problem, to achieve the effect of complete shape, simple structure and convenient overall replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

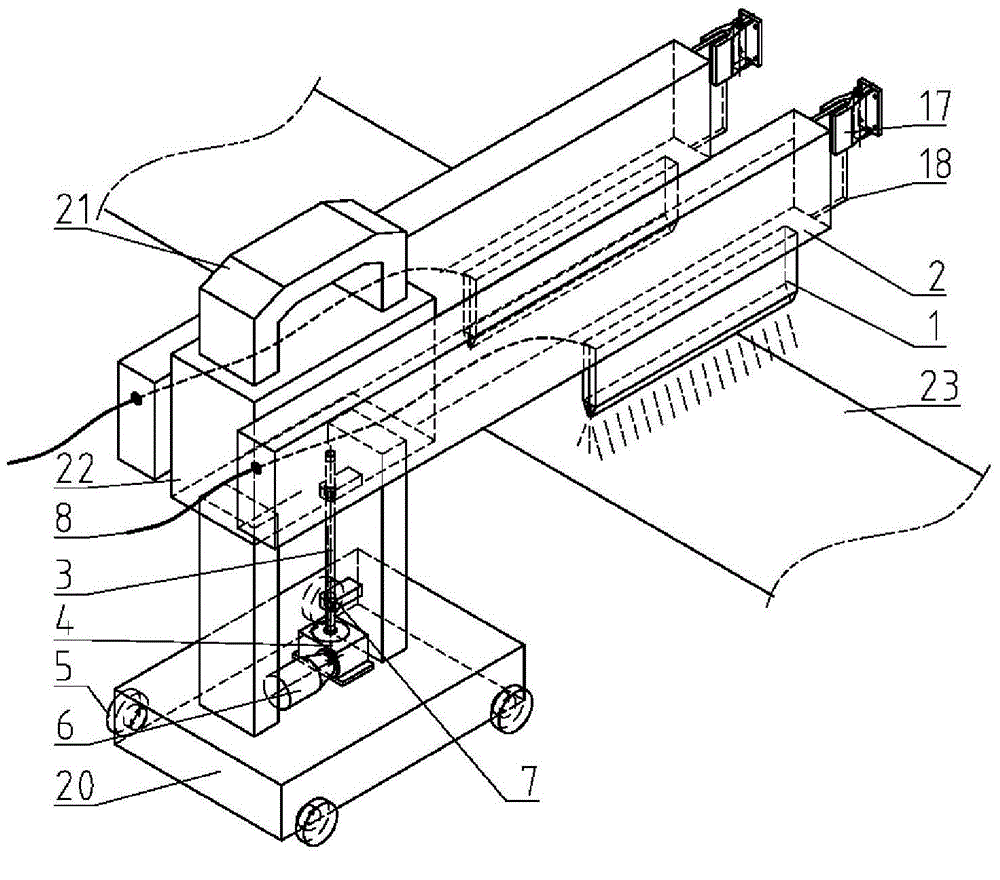

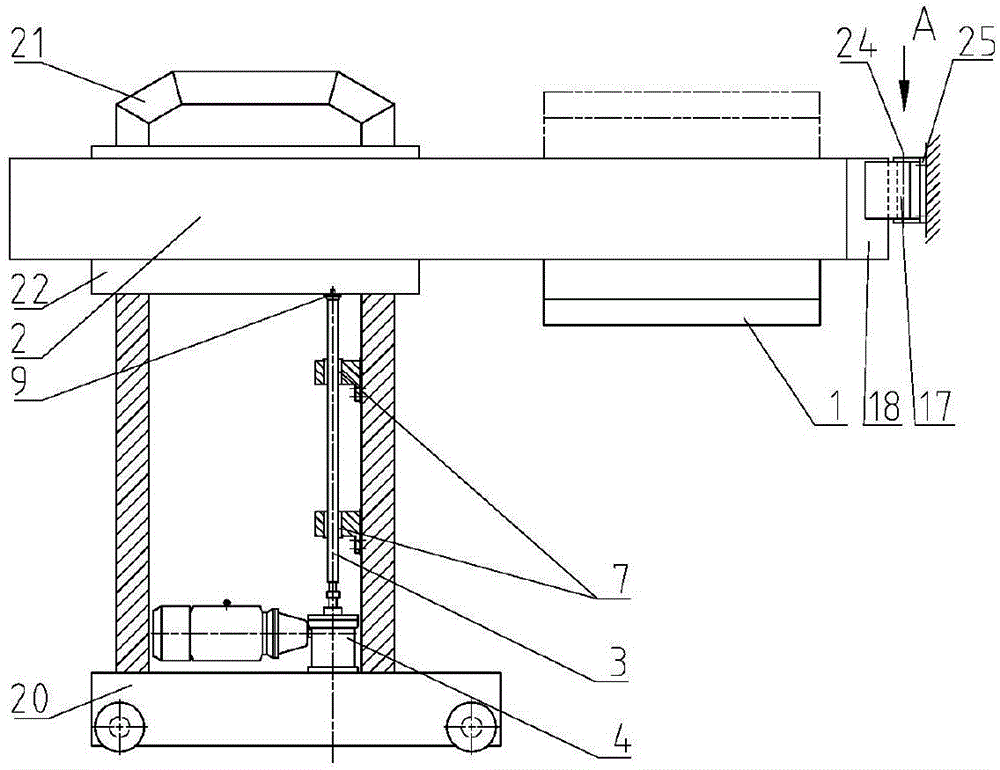

[0032] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

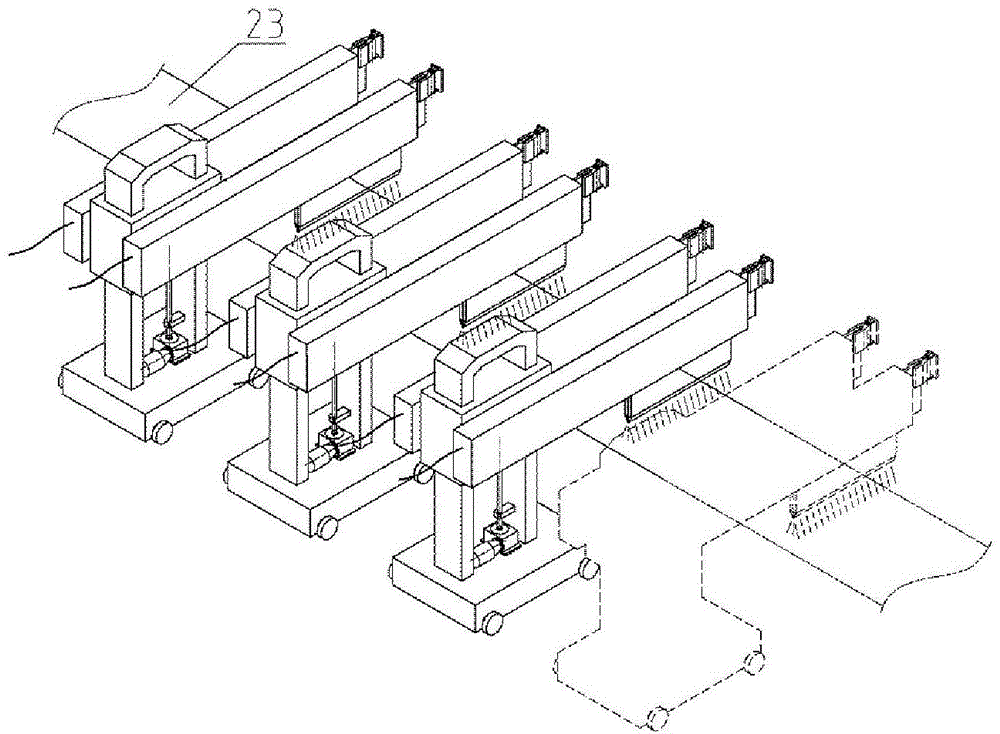

[0033] The electrostatic powder spraying trolley of the present invention is used to install the terminal sprayer in the electrostatic powder spraying device on a mobile machine that can swing up and down or left and right respectively. It is a kind of equipment that realizes electrostatic powder spraying in downward, horizontal, upward and multi-dimensional directions in different states.

[0034] see figure 1 , the electrostatic powder spraying trolley includes a base 20 with wheels 5 and a frame 21 fixedly installed on the base 20 . The shape of the vehicle frame 21 is an inverted "U" shape, and a sliding bracket 22 that can move up and down along the vehicle frame is set on the two columns, and a cantilever beam 2 is install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com