Method for preparing fermented product filtrate by fermenting rice with lactobacillus casei, and application of fermented product filtrate

A technology of Lactobacillus casei and fermented products, applied in the field of Lactobacillus casei fermenting rice to prepare fermented product filtrate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] The preparation of embodiment 1 Lactobacillus casei rice fermentation product filtrate

[0066] The medium contains 20% rice and 80% drinking water, and the two are mixed and kept at 70° C. for 20 minutes. After cooling, inoculate Lactobacillus casei at 27-40°C for static culture for 24 hours. At this time, the pH value of the fermentation system is less than 4, and the filtrate is obtained by filtering with a 40-mesh sieve, adding arginine to the filtrate to adjust the pH value to 5.0-6.0, and sterilizing at 80°C-105°C for 20 minutes to obtain the fermentation product filtrate.

Embodiment 2

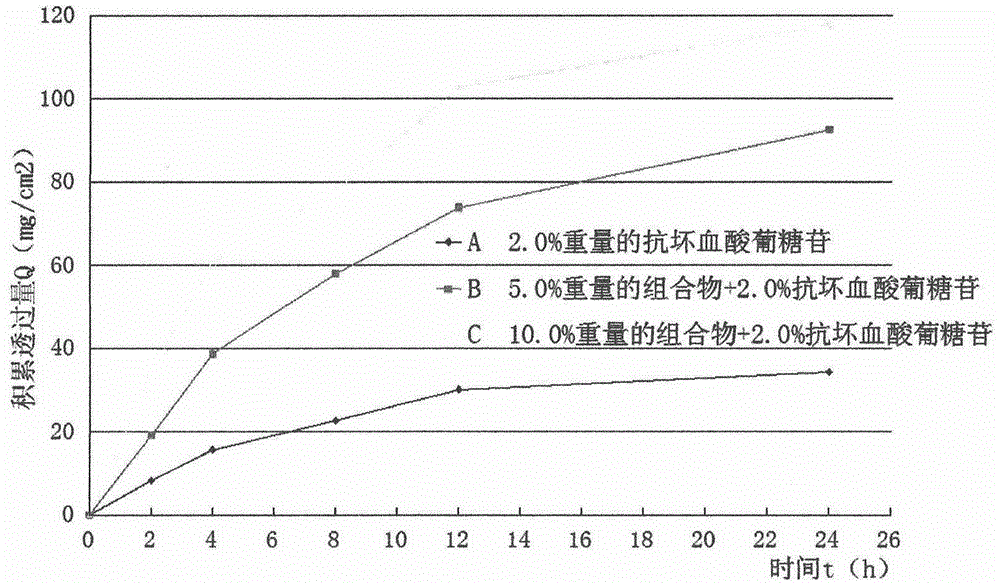

[0067] Embodiment 2 Penetration-promoting effect test

[0068] 1 material

[0069] 1.1 Epidermal stem cells were isolated and cultured in vitro to obtain a three-dimensional skin reconstruction model.

[0070] 1.2 Instruments High performance liquid chromatography LC-VP (Shimadzu, Japan); constant temperature gas bath.

[0071] 1.3 Drug reagent Ascorbyl glucoside; the fermentation product obtained in Example 1; all reagents used are analytically pure.

[0072] 2 methods

[0073] 2.1 Use high performance liquid chromatography to analyze and determine the content of ascorbic acid.

[0074] 2.2 Release solutions A to C use physiological saline as a solvent.

[0075] Group A is a control group without penetration enhancer, which is 2.0% by weight of ascorbyl glucoside physiological saline solution;

[0076] Group B adopts the fermented product filtrate prepared in Example 1, which is a composition physiological saline solution of 5.0% by weight, and wherein the concentration ...

Embodiment 3

[0084] Embodiment 3 acute toxicity test

[0085] The rice fermentation product filtrate of Lactobacillus casei in Example 1 was orally administered to each of five male and female mice in an amount of 10 g / kg, and when observed, it was confirmed that there were no deaths and abnormalities.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com