Frictional power generator employing dual-polymer composite film, preparation method thereof and vibration sensor

A technology of friction generator and double polymer, which is applied in the field of vibration sensor and friction generator, can solve the problems of friction generator output performance restriction development and application, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0074] The preparation method of the above-mentioned dual-polymer composite membrane will be described in detail below. The method includes:

[0075] (1) Prepare a liquid solution for the polymer coating.

[0076] The material used for the polymer cover layer is polydimethylsiloxane or polyvinylidene fluoride. Specifically, polyvinylidene fluoride is dissolved in dimethylacetamide (DMA) to form a liquid solution. Polydimethylsiloxane itself is liquid and can be directly applied to step (2). When polydimethylsiloxane is used for the polymer covering layer, polydimethylsiloxane and curing agent (vulcanizing agent, usually at a ratio of 10:1) are required. The curing agent used is a commercially available conventional curing agent, such as Dow Corning 184.

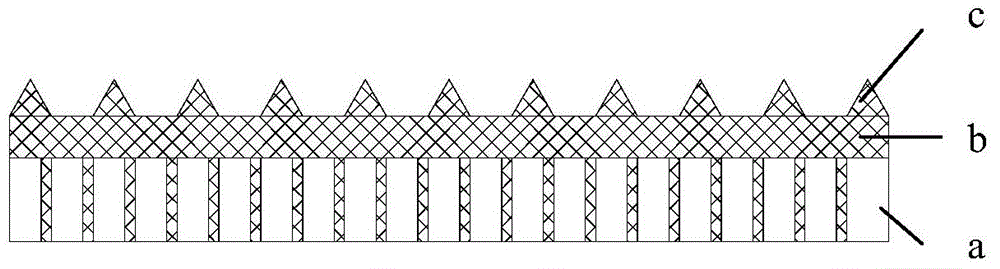

[0077] (2) Uniformly coat the polymer covering layer with a liquid solution on the surface of the polymer porous membrane layer. The material used for the polymer porous membrane layer is polypropylene porous membrane, p...

Embodiment 1

[0107] The size of the triboelectric generator is 3cm×1.2cm, and the total thickness is about 300μm. The triboelectric generator 1 includes a first electrode layer 11 , a first polymer insulation layer 12 , and a second electrode layer 13 which are stacked. The material used for the first polymer insulating layer 12 is a double polymer composite film. The preparation method of the friction generator will be described in detail below.

[0108] 1. Preparation of Dual Polymer Composite Membranes

[0109] Add curing agent (Dow Corning 184) to polydimethylsiloxane (Dow Corning) (mass ratio: 1:10) to obtain a liquid solution for the polymer covering layer. The polymer covering layer is uniformly coated on the surface of the polymer porous membrane layer (polypropylene porous membrane, Xinxiang Zhongke GRE-16P) with a liquid solution. The thickness of the polymer porous membrane layer is 15 μm. The side of the polymer porous membrane layer coated with the liquid solution for the ...

Embodiment 2

[0115] The size of the triboelectric generator is 3cm×1.2cm, and the total thickness is about 300μm. The triboelectric generator 1 includes a first electrode layer 11 , a first polymer insulation layer 12 , and a second electrode layer 13 which are stacked. The material used for the first polymer insulating layer 12 is a double polymer composite film. The preparation method of the friction generator will be described in detail below.

[0116] 1. Preparation of Dual Polymer Composite Membranes

[0117]Add curing agent (Dow Corning 184) to polydimethylsiloxane (Dow Corning) (mass ratio: 1:10) to obtain a liquid solution for the polymer covering layer. The polymer covering layer is uniformly coated on the surface of the polymer porous membrane layer (polypropylene porous membrane, Xinxiang Zhongke GRE-16P) with a liquid solution. The thickness of the polymer porous membrane layer is 15 μm. The side of the polymer porous membrane coated with the liquid solution for the polymer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com