Mining vacuum feeder switch device with isolating fractures

A feed switch, vacuum technology, applied in vertical pull isolation switchgear, switchgear components, electric switches, etc., can solve the problems of increased safety risk, large size, and no obvious isolation fracture in explosion-proof switches, and achieves a high level of improvement. safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

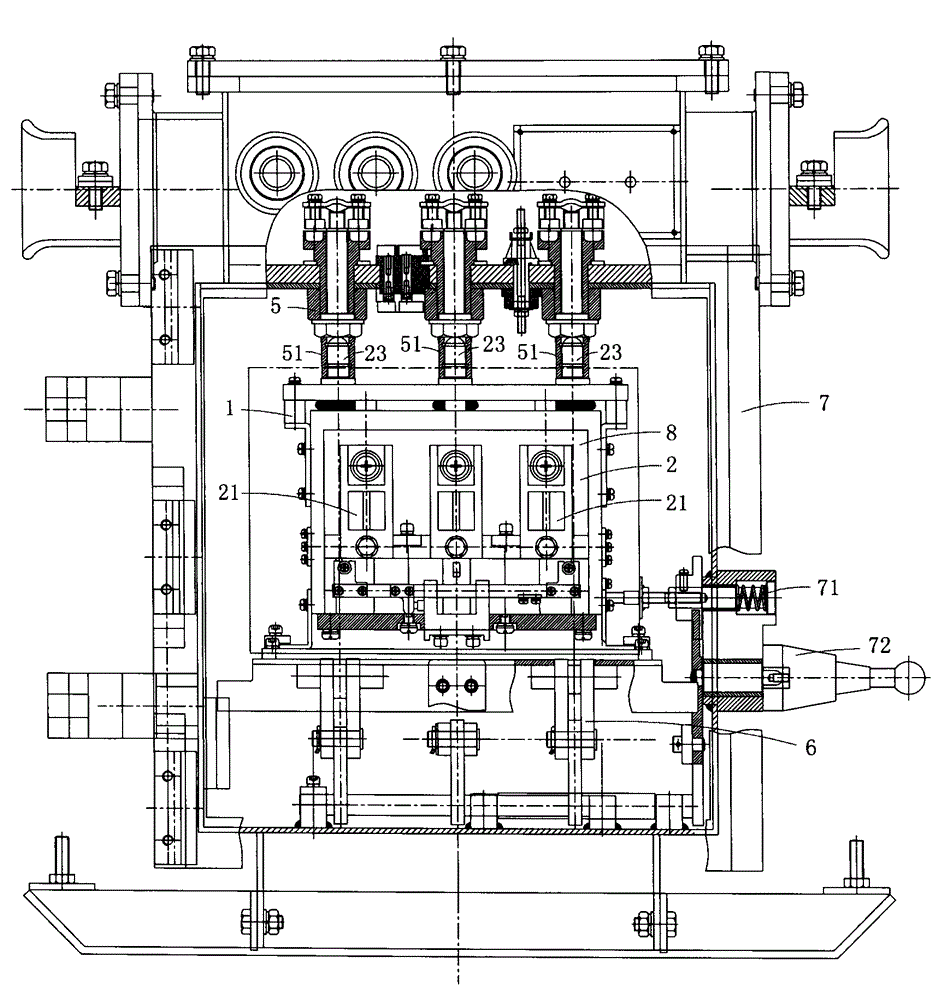

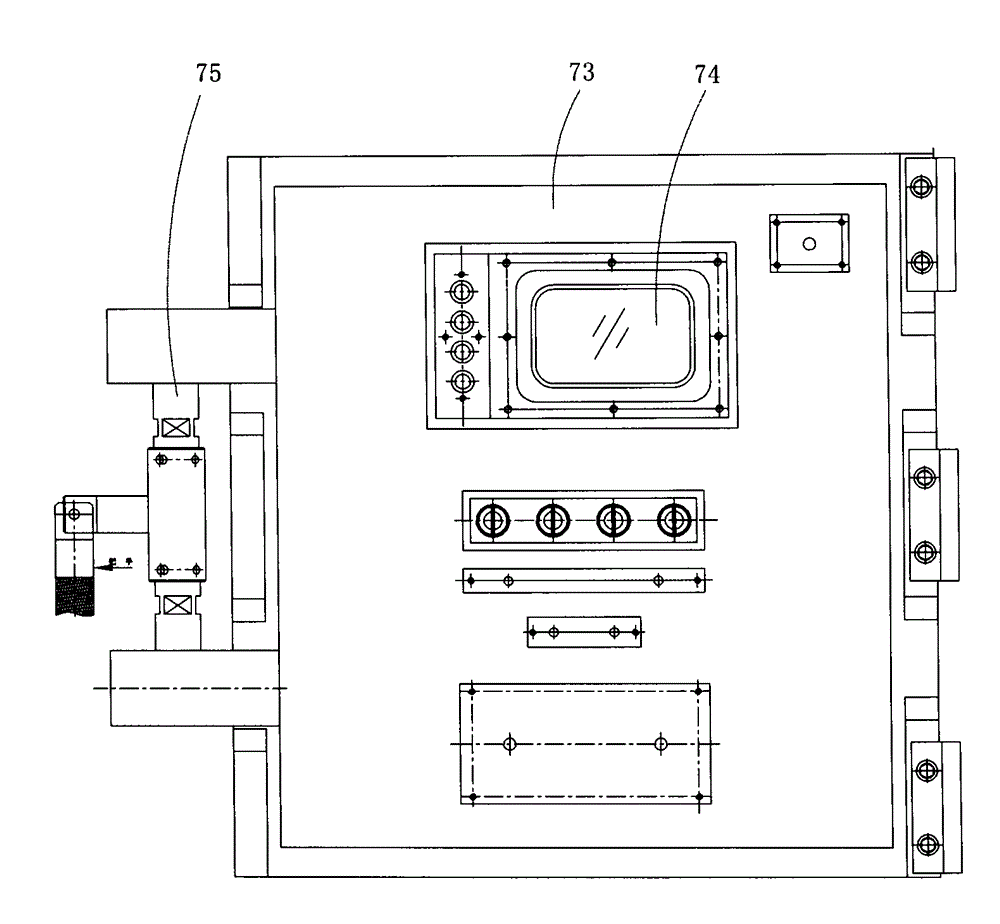

[0017] figure 1 with figure 2 A first embodiment of the invention is shown, in which figure 1 It is a schematic diagram of the internal structure of the first structure of the present invention; figure 2 yes figure 1 A schematic diagram of the structure of the vacuum feed switchgear shown when viewed from the side.

[0018] This embodiment is a mine vacuum feed switchgear with an isolation fracture, see figure 1 with figure 2 As shown, it includes an explosion-proof housing 7, and an intelligent vacuum contactor 8 arranged in the explosion-proof housing and a conductive mechanism 5 electrically connected with the vacuum contactor; Displacement mechanism 6; the intelligent vacuum contactor is provided with a plug-in power supply side electric column 23, and the conductive mechanism is provided with a plug-in power supply side electric sleeve 51; the intelligent vacuum contactor is driven by the displacement mechanism to drive the The electric column on the power supply...

Embodiment 2

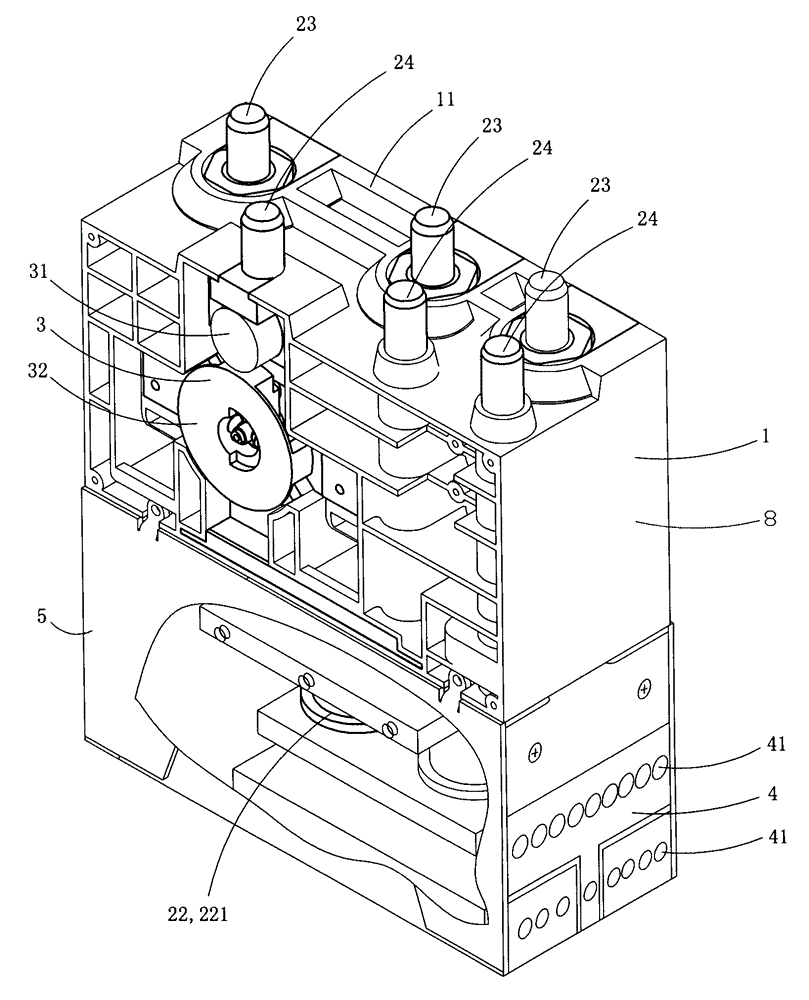

[0025] Figure 3 to Figure 6 Another embodiment of the invention is shown in which image 3 It is a schematic diagram of a three-dimensional structure of the intelligent vacuum contactor in the second structure of the present invention; Figure 4 yes image 3 A schematic diagram of the structure of the shown smart vacuum contactor viewed from the other side; Figure 5 yes image 3 A schematic diagram of the structure of the intelligent vacuum contactor shown when it is electrically connected to the conductive mechanism; Figure 6 yes image 3 A schematic diagram of the structure when the smart vacuum contactor and the conductive mechanism form an isolation fracture.

[0026] This embodiment is basically the same as Embodiment 1, the difference is: see Figure 3 to Figure 6 As shown, the intelligent vacuum contactor 8 used in this embodiment is different from that in Embodiment 1. The intelligent vacuum contactor includes a frame 1, a vacuum contactor 2 arranged on the fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com