Backside-illuminated CMOS sensor and manufacturing method thereof

A technology of a CMOS sensor and a manufacturing method, which is applied to radiation control devices and other directions, can solve problems such as lack of records, and achieve the effects of reducing etching area, improving imaging quality, and increasing effective circuit area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

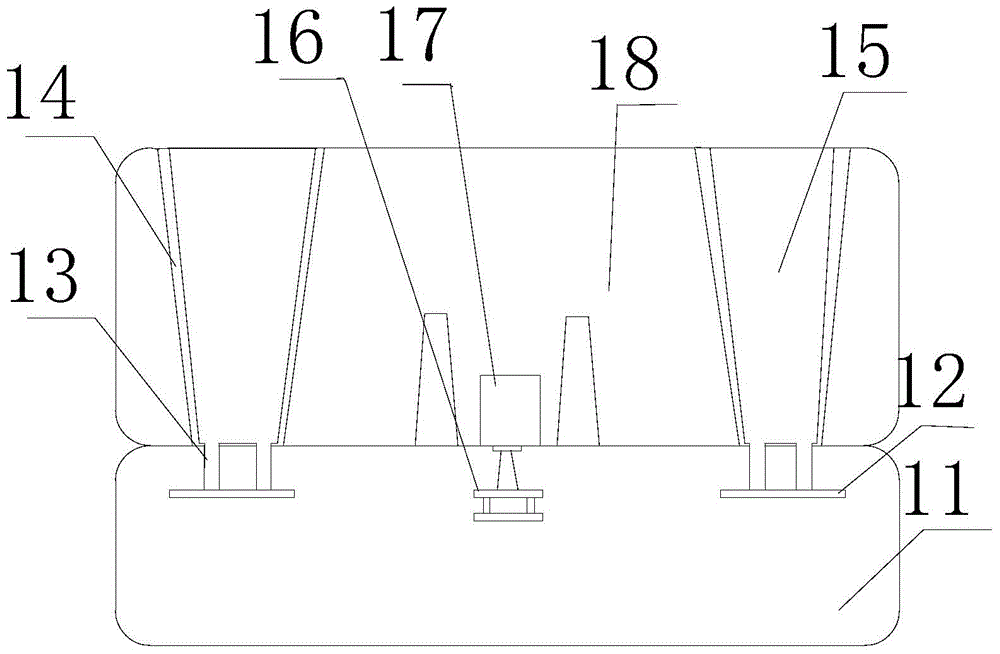

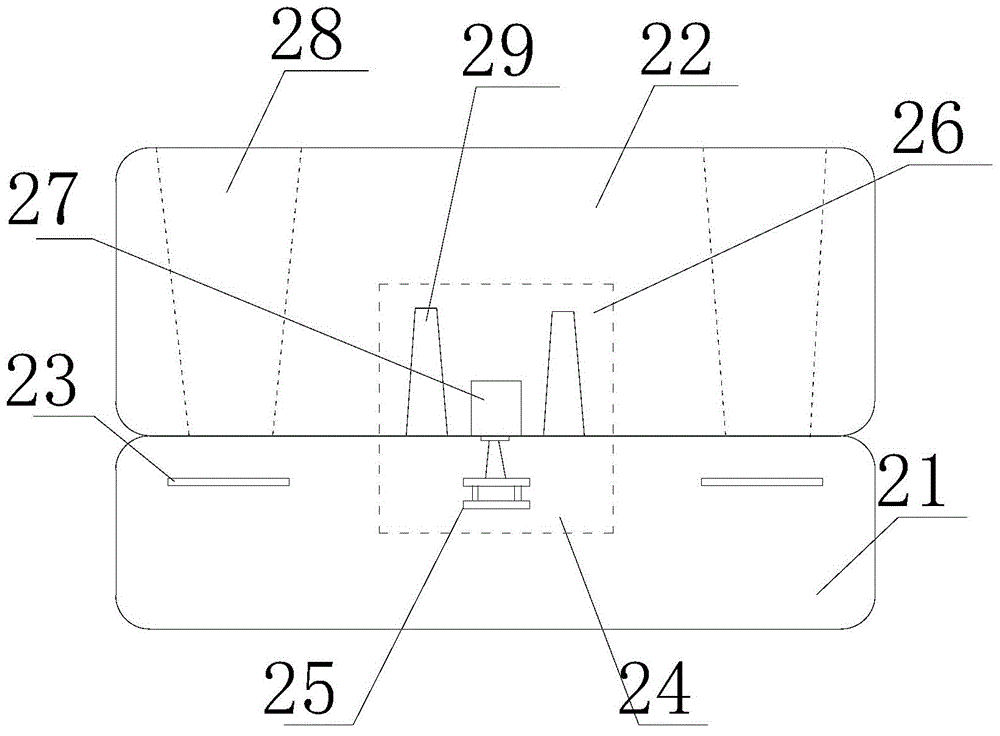

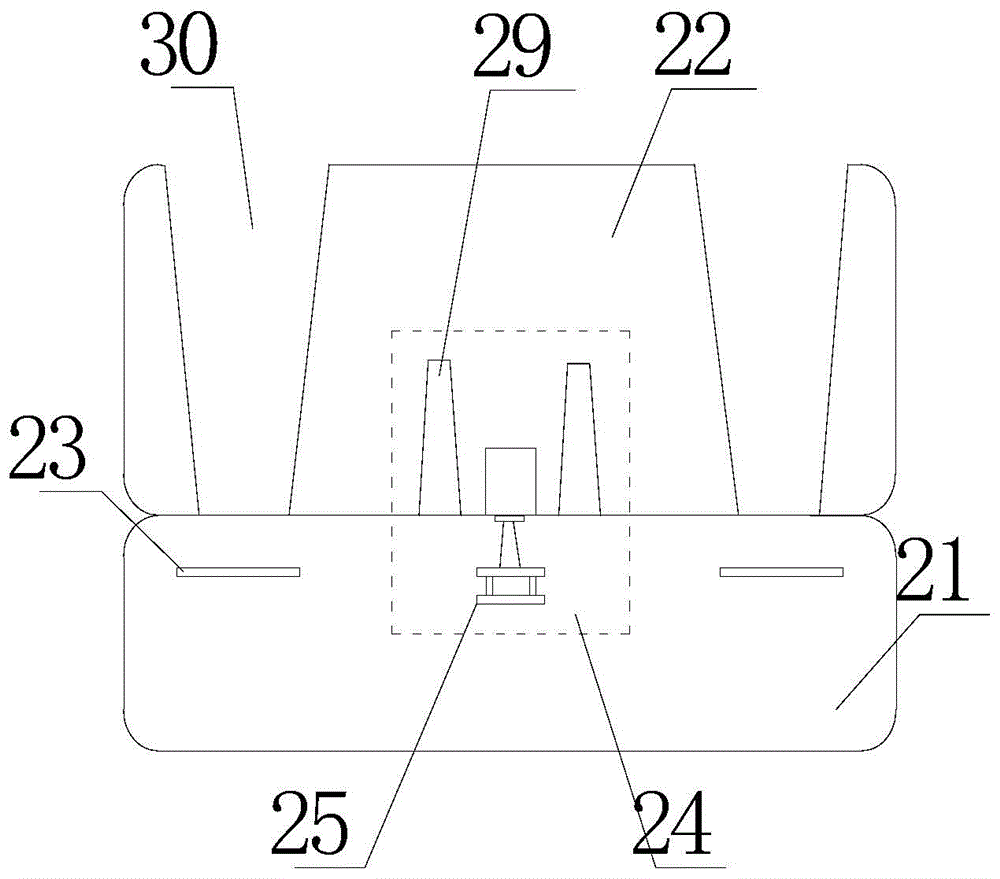

[0031] In the actual preparation process, if the area is 4127um×4127um=1.7E8um 2 The newly increased effective area of the COMS sensor can reach 55um×110um×26×4=6.3E6um 2 , thereby increasing the area of the adjustable device structure region by 6.3E6 / 1.7E8×100%≈3.7%, which greatly increases the effective area of the adjustable device structure of the CMOS sensor.

[0032] Preferably, an isolation structure such as a shallow trench isolation structure (STI), etc. is also provided around the above-mentioned newly added device structure 17 .

[0033] Further, a plurality of connecting wire structures are arranged in the dielectric layer 11 corresponding to the above-mentioned device layer 18, that is, a metal layer 12 is arranged at a position corresponding to each connecting pad 15, and the metal layer 12 is connected to the connecting wire 13 through the connecting wire 13. The disk 15 is connected; at the position corresponding to the above-mentioned newly added device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com