Real-person shoe type copying device and shoe tree manufacturing method based on single-eye multi-angle-of-view robot vision

A technology of copying device and machine vision, which is applied in the fields of instruments, image data processing, special data processing applications, etc., can solve the problems of high manufacturing cost, high computational complexity and difficult registration of shoe lasts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

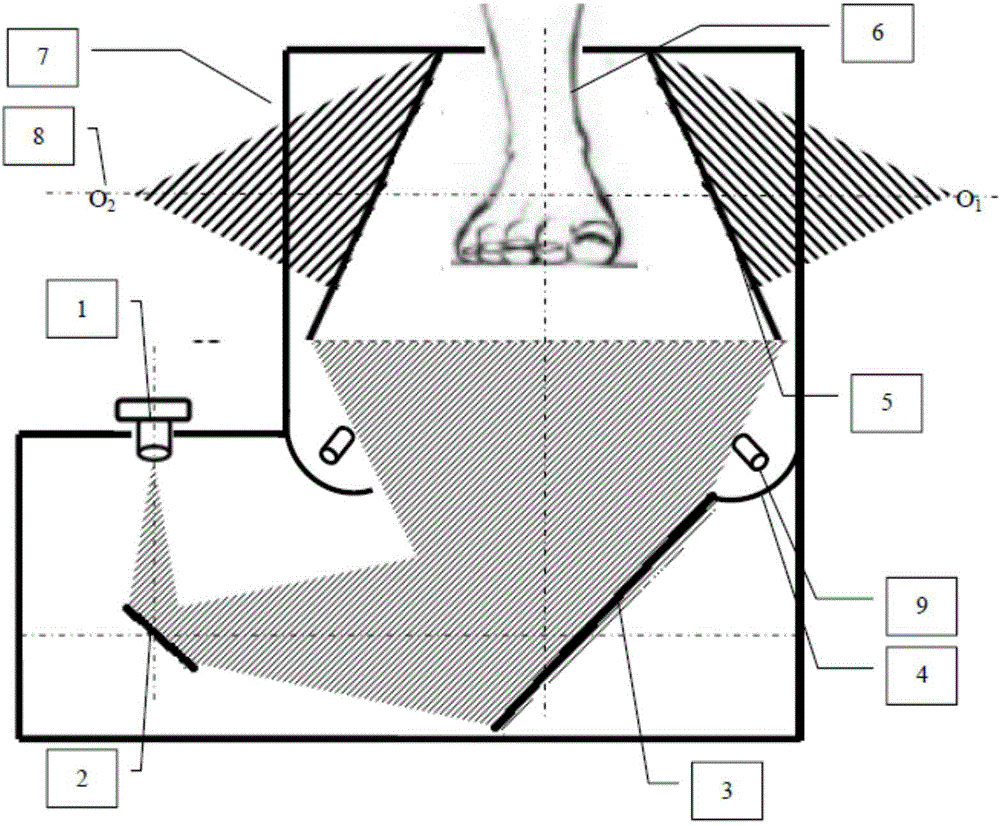

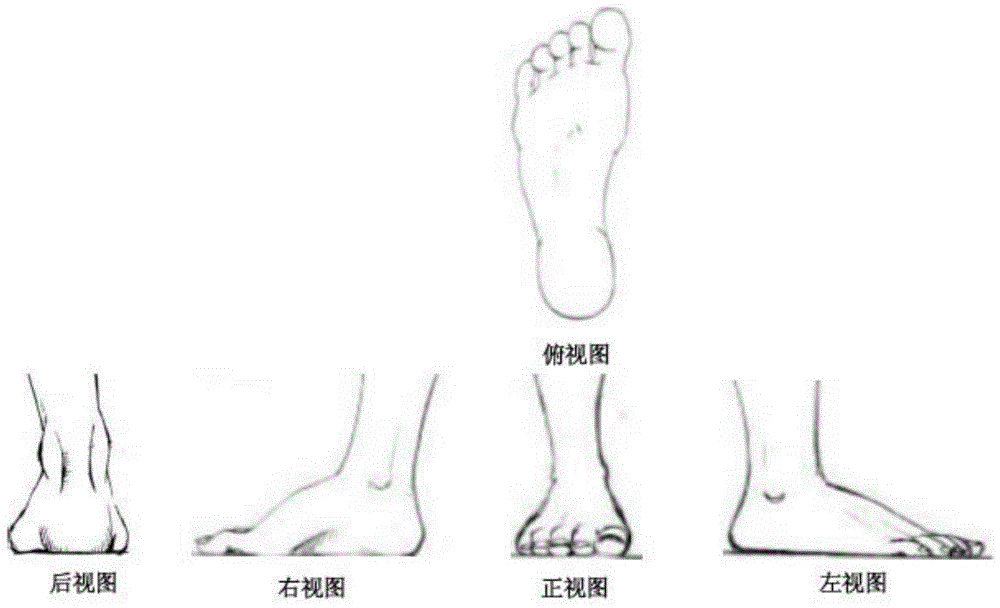

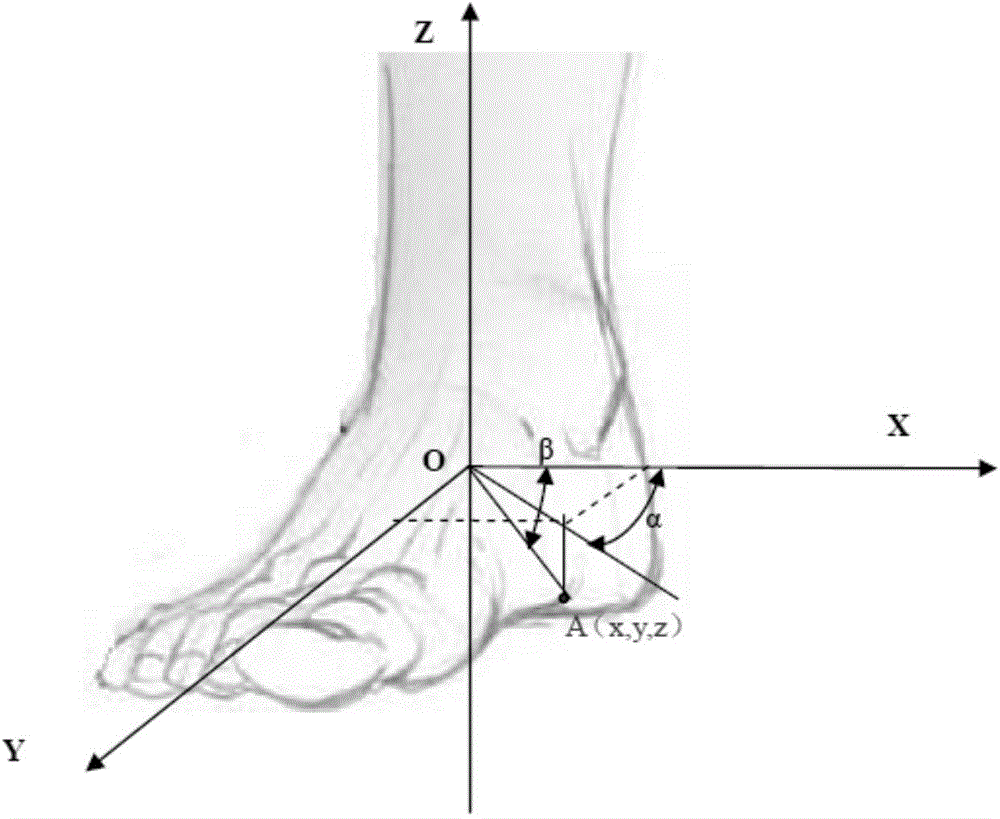

[0095] Reference Figure 1~11 , A monocular multi-view machine vision real-life shoe reproduction device and shoe last manufacturing method, through a monocular multi-view stereo vision box for shooting real human foot images in 5 different perspectives and realizing the three-dimensional reconstruction of real human foot Build and automatically generate a computer for 3D printing and output STL files.

[0096] The monocular multi-view stereo vision box is composed of a high-definition camera 1, a first reflecting mirror surface 2, a second reflecting mirror surface 3, a rectangular white LED mixed light source 9 and a flat mirror rectangular bucket-shaped cavity. To obtain images of real human feet in 5 different viewing angles; the rectangular bucket cavity of the plane mirror is composed of 4 isosceles trapezoidal mirrors, the mirror cavity is large and small, and the mirror faces the inside of the cavity; the optical axis of the high-definition camera and the first A reflecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com