Polymerization process condition optimization method taking polyolefin microscopic quality as target

A polymerization process and micro-quality technology, applied in the direction of instruments, adaptive control, control/regulation systems, etc., can solve the problems of low efficiency and long time consumption, and achieve the effects of energy saving, emission reduction, time shortening, and online control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The method of the present invention will be described in detail below with reference to the drawings and embodiments. The meaning of each parameter appearing below is detailed in the symbol description table.

[0033] In an embodiment of the present invention, the steps are as follows:

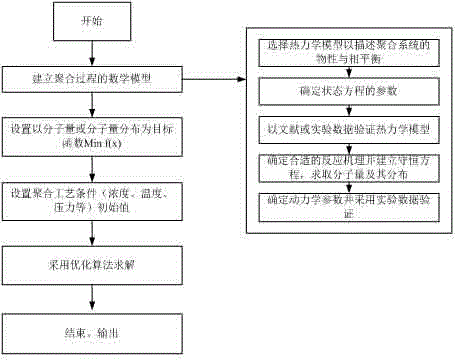

[0034] 1) Establish a mathematical model of the olefin polymerization process, the steps are as follows figure 1 As shown in the right block diagram.

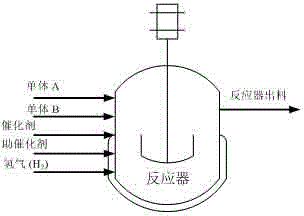

[0035] ① First determine the form and operation method of the reactor. Industrial olefin polymerization devices include vertical tank reactors, loop reactors, horizontal stirred bed reactors and fluidized bed reactors, etc. The operating states include slurry phase, bulk phase, gas phase, and supercritical fluid. . However, different types of reactors can be regarded as continuous stirred tank reactors (CSTR) such as figure 2 As shown, or a combination of CSTR.

[0036] ②Select the thermodynamic state equation of the polymerization system an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com