Multi-point excitation type airplane load model testing device and application method thereof

A multi-point excitation and test device technology, applied in measurement devices, teaching models, educational appliances, etc., can solve the problems of inability to accurately and deeply analyze dynamic response and long-term settlement laws, lack, and inability to set up test instruments, etc. The transmission form is real, the force condition is reasonable, and the test method is direct.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

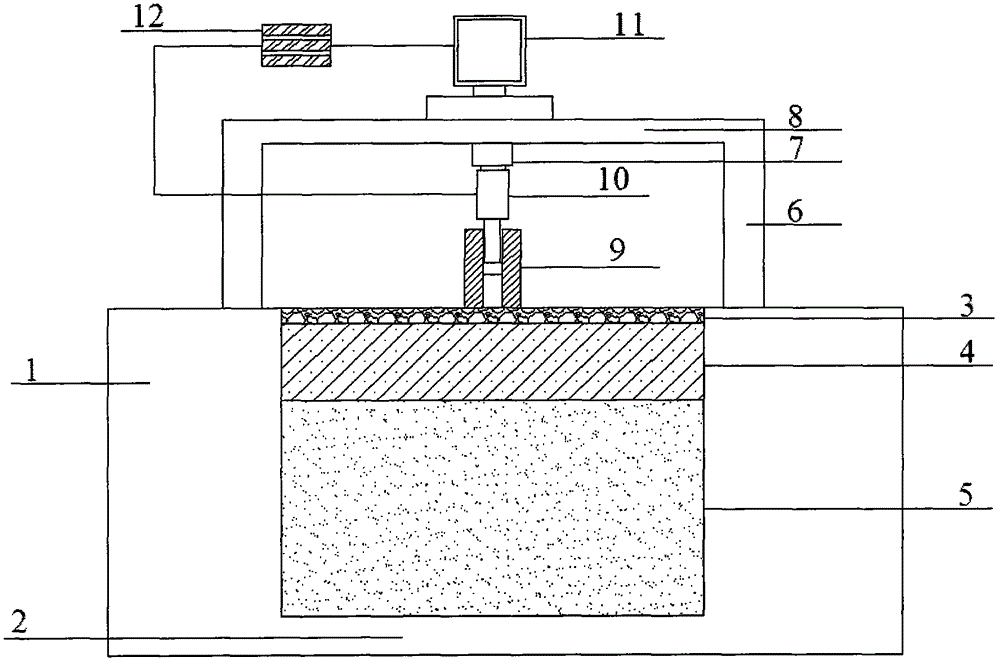

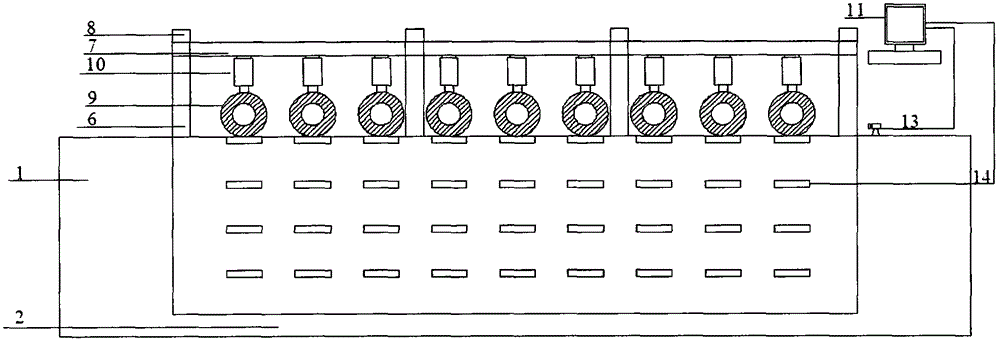

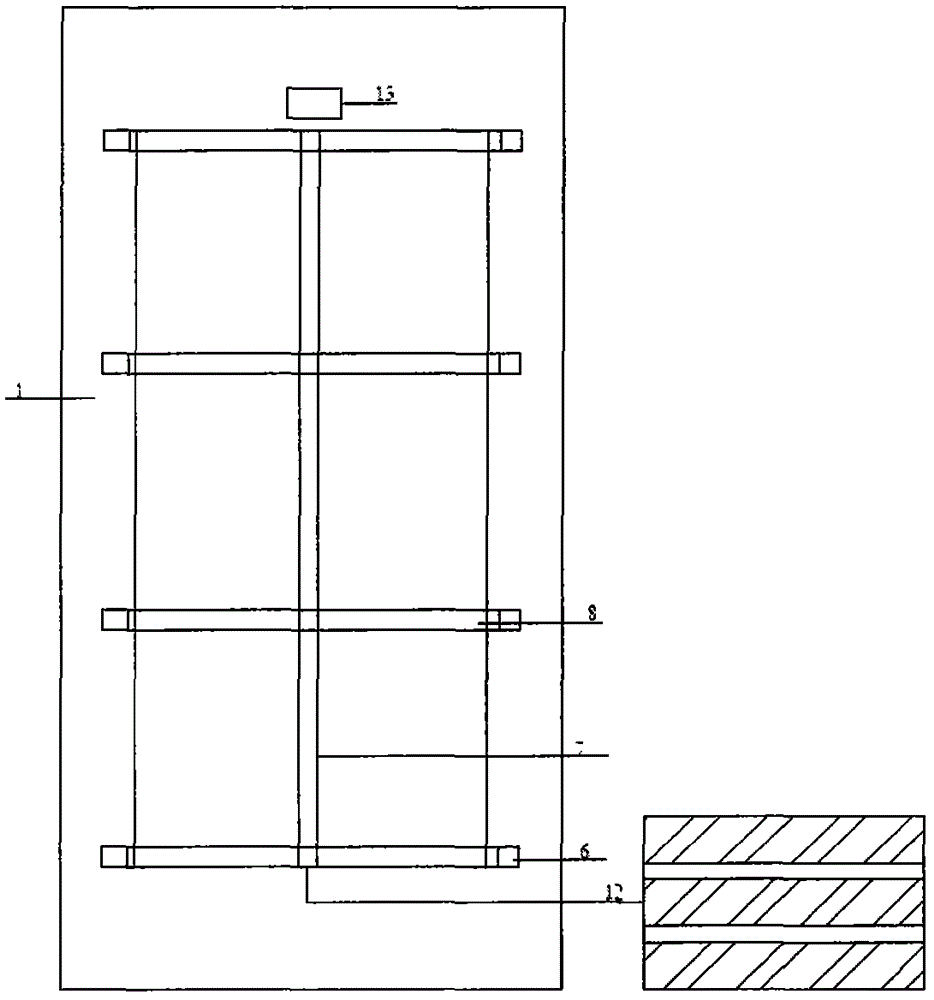

[0016] Such as figure 1 , figure 2 As shown, the airstrip model groove formed by the concrete wall 1 and the concrete floor 2 constitutes the lower foundation structure of the experimental device, and the pavement layer 3, roadbed 4 and foundation soil 5 are laid in the airstrip model groove in proportion to the real airstrip , the wall 1 restricts the lateral displacement of the pavement layer 3, subgrade 4 and foundation soil 5, the concrete floor 2 provides bottom support, and the frame vertical beam 6, frame longitudinal beam 7 and frame beam 8 are connected to form the upper support system of the test device , the electro-hydraulic servo actuator 10 is installed under the frame longitudinal beam 7, the computer control system 11 controls and provides load parameters, and the electro-hydraulic servo oil source 12 provides power to control the electro-hydraulic servo actuator 10 to generate corresponding loads, through direct The connected real aircraft tire 9 is transfer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com