Anti-surge system of centrifugal type refrigerating unit

A refrigeration unit and anti-surge technology, which is applied in the direction of refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of compressor resource waste, reduce system high and low pressure differences, and increase power consumption, so as to avoid resource and energy waste Waste, reduce system pressure difference, high energy utilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

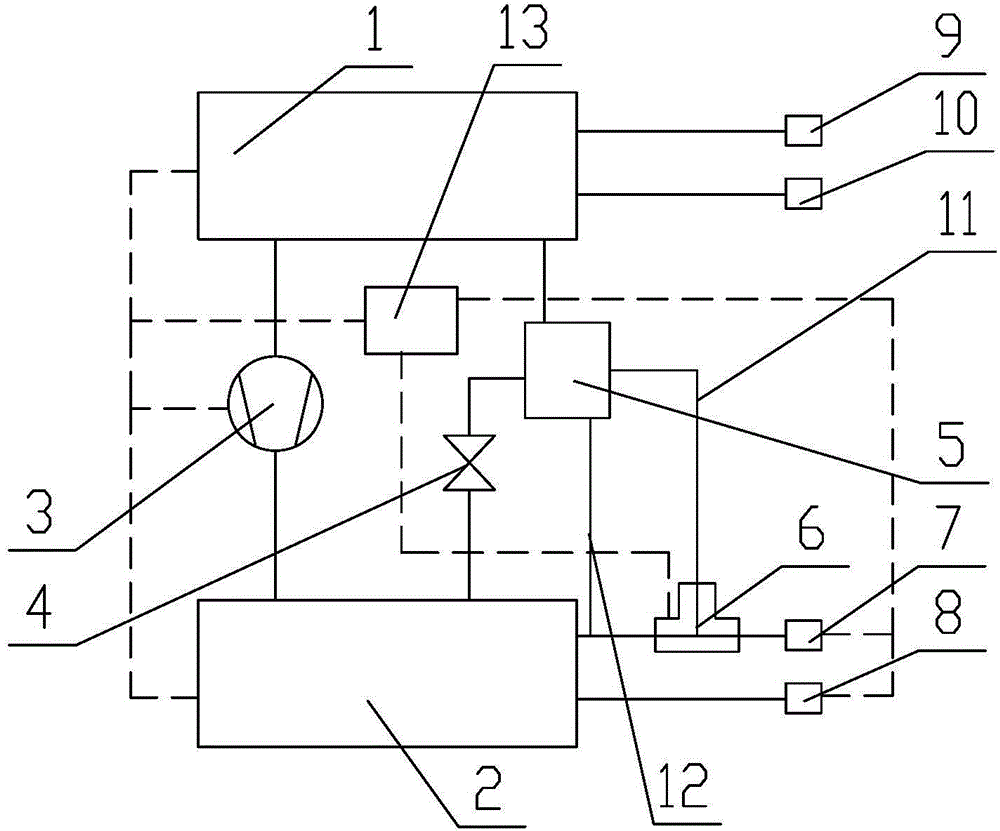

[0026] Such as figure 1 Shown is the specific connection structure of the anti-surge system of the centrifugal refrigeration unit proposed in the specific embodiment of the present invention. The connection mode between the various components in the refrigerating unit in the present invention is roughly the same as that of the refrigerating unit in the prior art, including a condenser 1 and an evaporator 2, and the condenser 1 and the evaporator 2 are respectively connected There is a compressor 3 and a throttling device 4 . The condenser 1 is connected with a cooling water outlet 9 and a cooling water inlet 10. The cooling water inlet 10 is used for the external cooling water to enter the condenser 1 and exchange heat with the refrigerant in the condenser 1. The cooling water outlet 9 It is used ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com