A multi-purpose valve device

A multi-purpose, valve device technology, applied in valve devices, multi-way valves, valve heating/cooling devices, etc., can solve the problems of inaccurate control of outlet flow, single inlet and outlet, and inability to save water. It achieves the effect of simple structure, convenient operation and preventing the outlet from freezing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

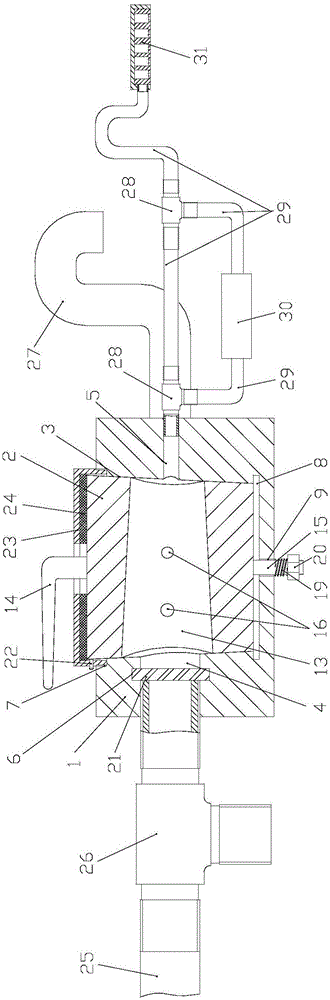

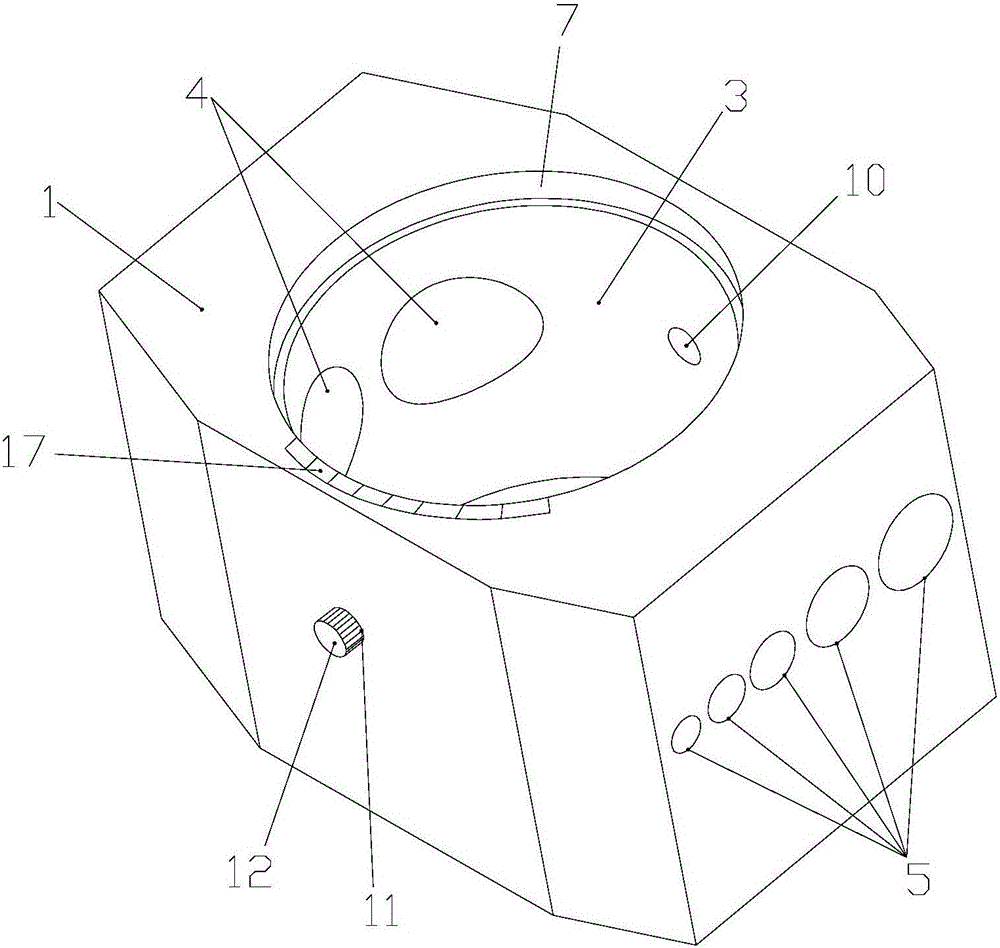

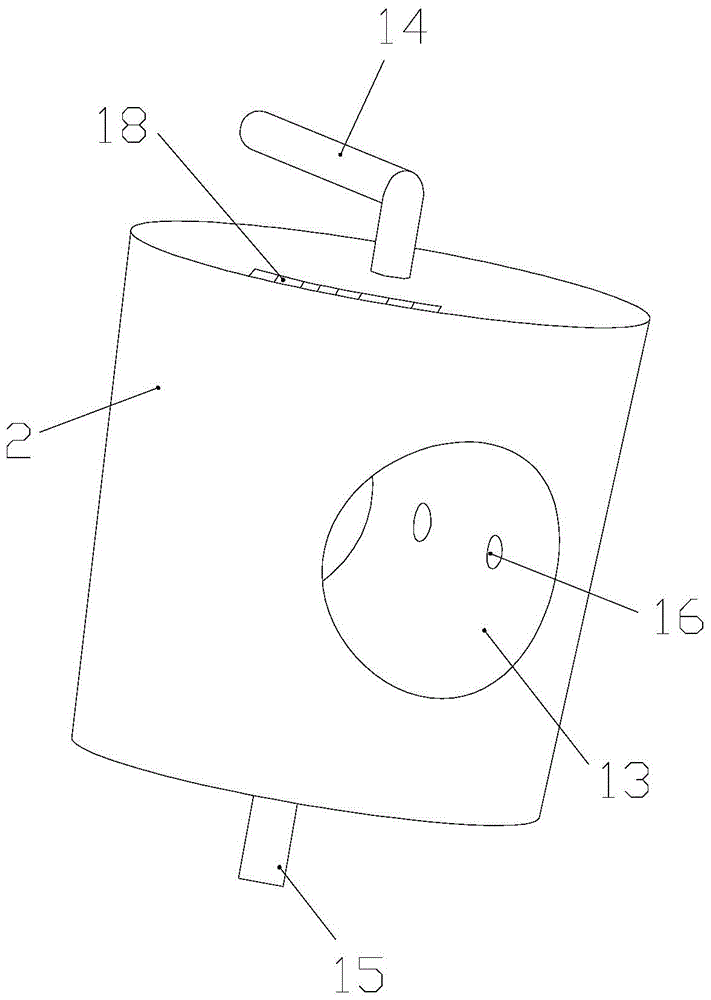

[0025] Attached below Figure 1-6 Embodiments of the present invention are described.

[0026] A multi-purpose valve device has a valve body 1 and a valve core 2. The valve body 1 is provided with a valve body check 3 and its inner surface is conical. The outer surface of the valve core 2 is conical and is in line with the valve The inner conical surface of the body seam 3 is tightly fitted, and the top of the valve body seam 3 is shaped on a prism 7 and the inner cylindrical surface of the ridge 7 is formed with a screw thread that is screwed with the valve core cover 23, and the valve core The cover 23 is formed with a top wire hole and the top wire 22 is screwed with the top wire hole to tighten the outer conical surface of the spool 2. A gasket 24 is arranged between the spool cover 23 and the spool 2, and the spool 2 The top is provided with a spool handle 14 bent at 90°, one end of the spool handle 14 passes through the spool cover 23 and the gasket 24 and is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com