Multi-spring steel plate damper

A shock absorber, multi-spring technology, applied in the direction of spring/shock absorber, shock absorber, shock absorber, etc., can solve the problems of hydraulic shock absorber cost, high cost, unstable center of gravity of spring shock absorber, etc. Achieve the effect of eliminating high-frequency transmission, obvious vibration reduction and noise reduction, and stable center of gravity of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

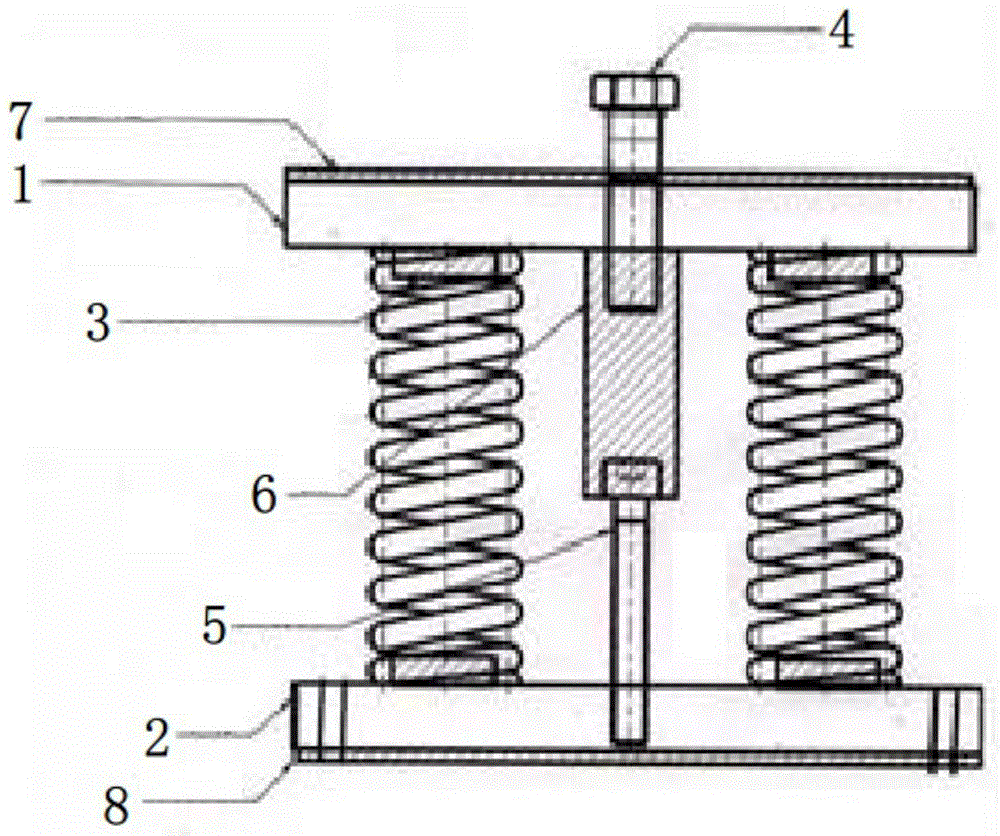

[0017] Example: figure 1 It is a schematic structural view of the multi-spring steel plate shock absorber of the present invention. It can be clearly seen from the figure that a kind of multi-spring steel plate shock absorber of the present invention comprises an upper steel plate 1, a lower steel plate 2, several springs 3 and upper fixing bolts 4, The lower fixing bolt 5, wherein a number of springs 3 evenly arranged are fixed between the upper steel plate 1 and the lower steel plate 2, and the upper fixing bolt 4 and the opening corresponding to the upper fixing bolt 4 are arranged in the center of the upper steel plate 1. A hollow limit tube 6 is fixed below the center of the steel plate 1 , and a lower fixing bolt 5 and an opening corresponding to the lower fixing bolt 5 are arranged in the center of the lower steel plate 2 .

[0018] The present invention adopts a plurality of springs 3 evenly arranged between the upper steel plate 1 and the lower steel plate 2, so that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com