Timing chain transmission system and engine

A chain transmission and engine technology, applied in the direction of engine components, machines/engines, mechanical equipment, etc., to achieve the effect of reducing assembly costs, reducing friction loss, and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

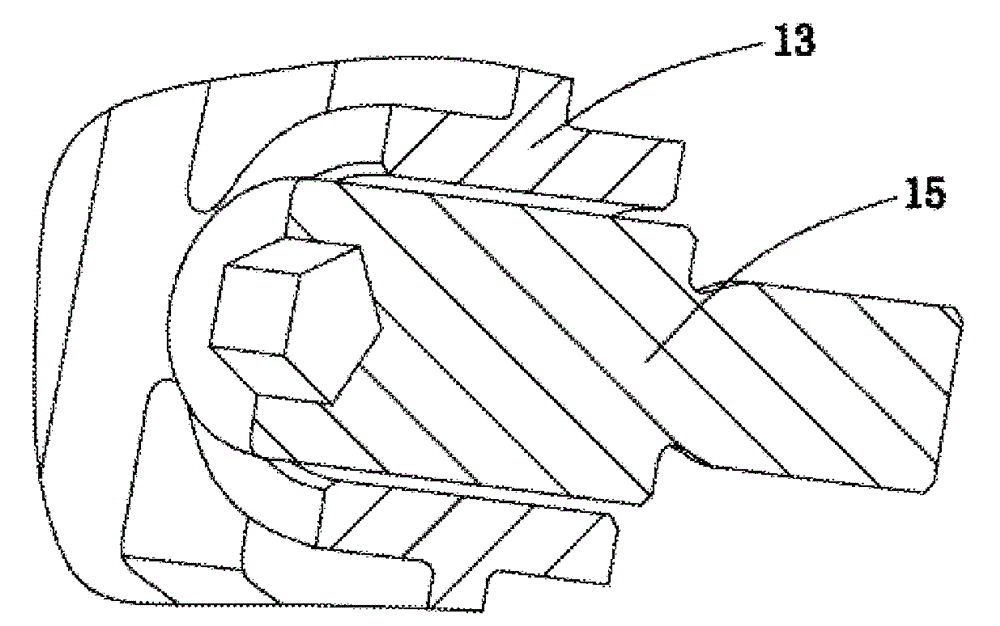

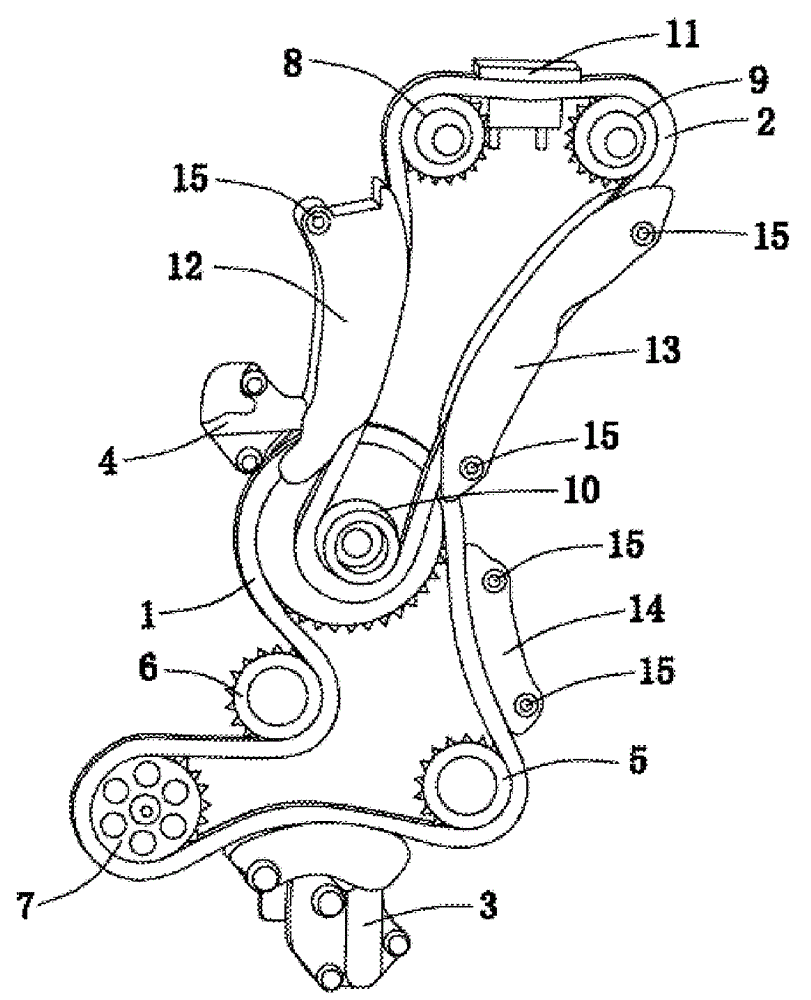

[0027] figure 1 A schematic diagram of a timing chain drive system according to an embodiment of the present invention is shown. exist figure 1 Among them, reference numeral 1 denotes a primary transmission chain, 2 denotes a secondary transmission chain, 3 denotes a primary chain tensioner, 4 denotes a secondary chain tensioner, 5 denotes a crankshaft sprocket, 6 denotes a balance shaft sprocket, 7 represents the oil pump sprocket, 8 represents the intake camshaft sprocket, 9 represents the exhaust camshaft sprocket, 10 represents the idler gear, 11 represents the guide rail between the camshafts, 12 represents the secondary chain tensioner arm, 13 represents the two Grade chain guide rail, 14 represents the first grade chain guide rail, and 15 represents the guide rail bolt.

[0028] As can be seen from the figure, the timing chain transm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com