Sealing connecting structure of casing of gas well

A connection structure and casing technology, which is applied in the direction of casing, drill pipe, drilling equipment, etc., can solve the problems of easy damage in hoisting and stabbing, small guide surface inclination, low processing efficiency, etc., to achieve easy stabbing, reduce Effect of stress concentration and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

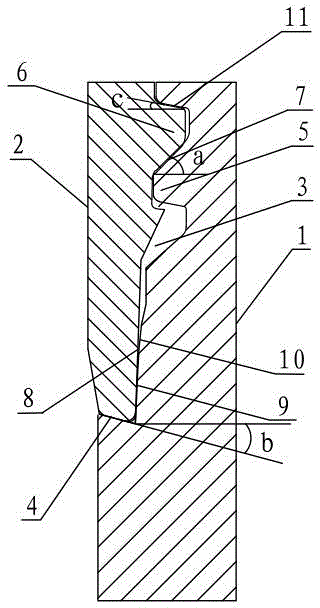

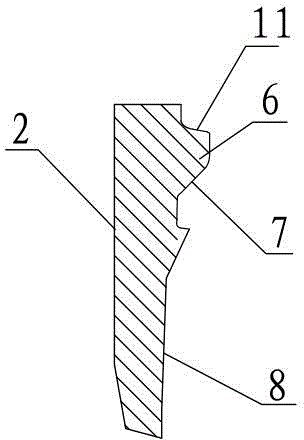

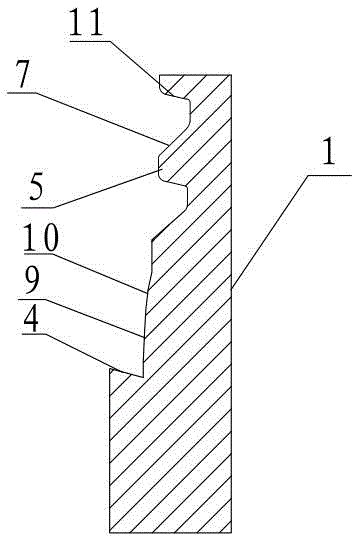

[0022] Such as figure 1 , figure 2 and image 3 Shown: a gas well casing sealing connection structure, including a male pipe head 1 and a female pipe head 2, the male pipe head 1 is inserted into the female pipe head 2, and the contact between the male pipe head 1 and the female pipe head On the surface are the threaded connection part, the oil storage relief groove 3, the sealing surface and the torque shoulder 4 in sequence. The thread 6, the external thread 5 and the internal thread 6 are partial trapezoidal threads, the inclination angle a of the guide surface 7 contacted between the external thread 5 and the internal thread 6 is 25 ° ~ 45 °, the internal thread The tooth height of 6 is 1.45~1.65mm, and the tooth height of external thread 5 is 1.65~1.85mm; the sealing surface is composed of the first tapered surface 8 on the inner wall of the female pipe head 2 and the spherical surface 10 and the outer wall of the male pipe head 1 respectively. The second conical surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com