FRP (fiber reinforce plastic) tube-concrete-multiple steel tube hollow combined single-box or multi-box multi-compartment beam

A technology of concrete and fiber reinforced concrete, applied in the direction of joists, girders, trusses, etc., can solve the problems of material consumption, easy to be corroded by the external environment, increase the self-weight of components, etc., to reduce local damage, good lateral stability, lightening The effect of the structure's own weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below with reference to the accompanying drawings and specific implementations.

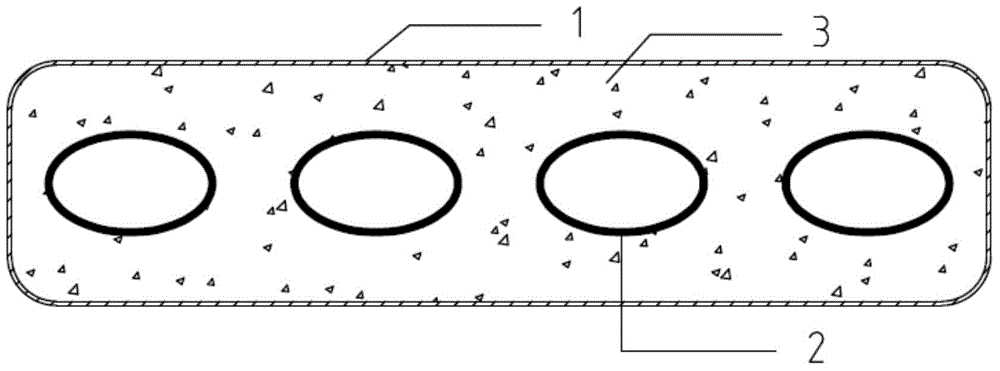

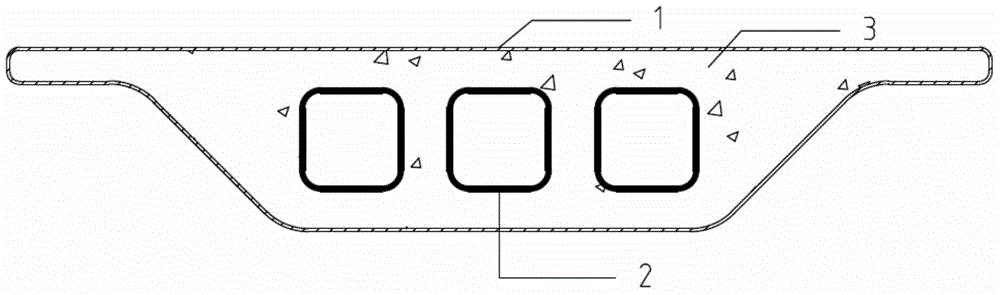

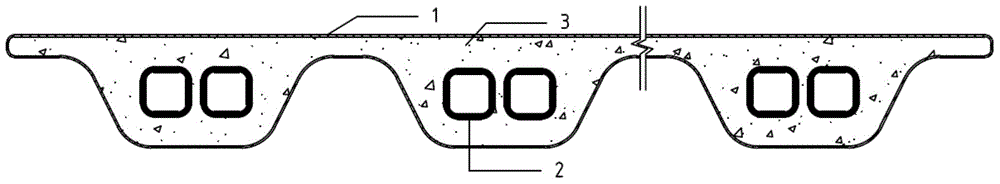

[0034] First, select the outer layer FRP pipe 1 and the built-in steel pipe 2. The built-in steel pipe 2 is sleeved into the outer FRP pipe 1, and the same end of the inner steel pipe 2 and the outer FRP pipe 1 are sealed, and the concrete 3 It is poured between the built-in steel pipe 2 and the outer FRP pipe 1 for maintenance.

[0035] The outer layer of FRP pipe 1 can be used in typical cross-sectional forms such as Figure 7 with Figure 8 As shown, but not limited to the above-mentioned cross-sectional form, the outer FRP tube 1 can be selected arbitrarily outside these cross-sectional forms.

[0036] The built-in steel pipe 2 can be used in typical cross-sectional forms such as Figure 9-13 As shown, but not limited to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com