Connecting joint for buckling-restrained brace and concrete frame beam

A technology of buckling restraint and connecting nodes, which is applied in the direction of building components, earthquake resistance, construction, etc., can solve the problems of strength reduction, poor stability of anchor bars, drawing damage, etc., achieve strength and stiffness improvement, improve engineering efficiency, and reduce stress concentration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with drawings and embodiments.

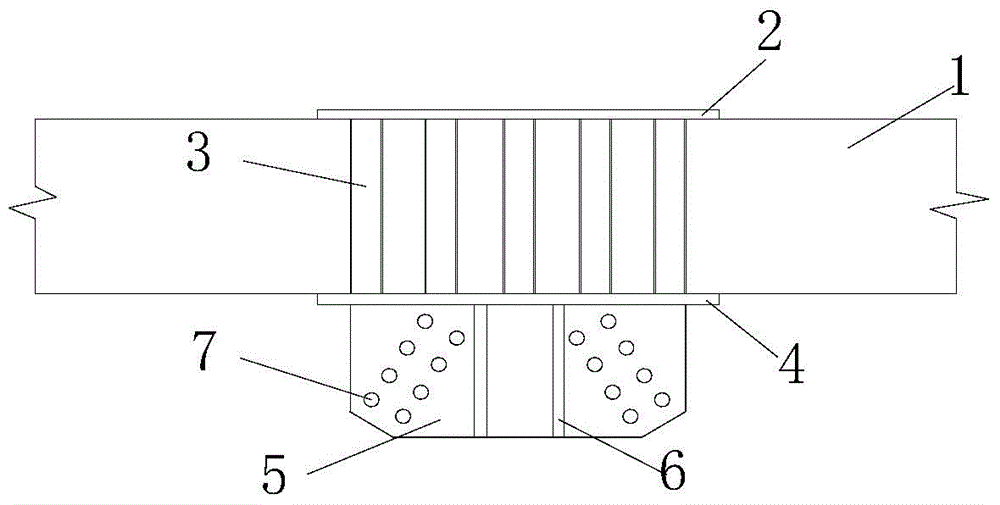

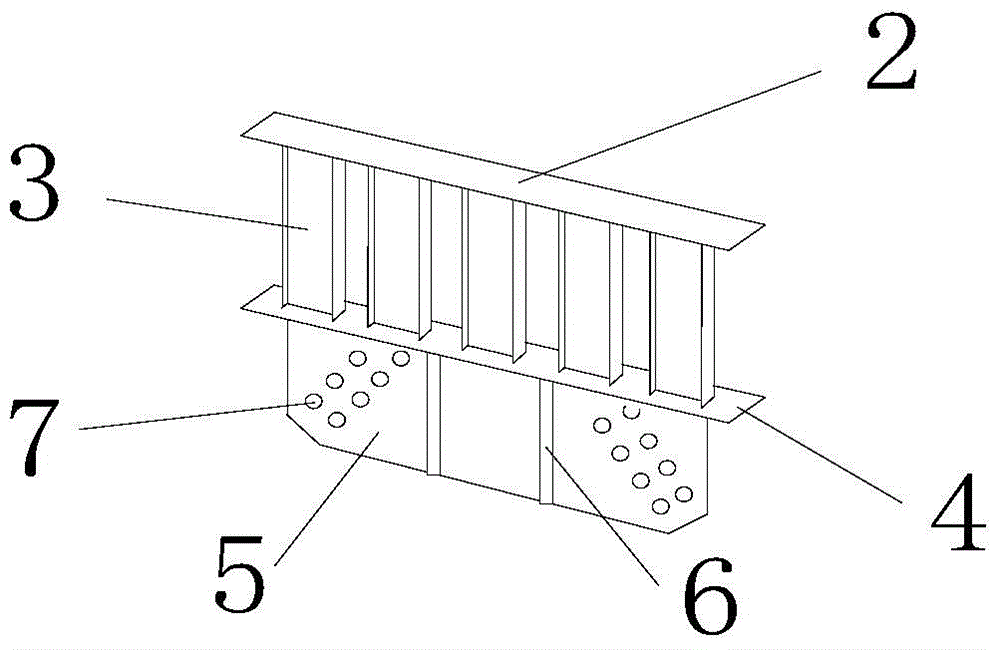

[0022] to combine figure 1 with figure 2 , the buckling-constrained support of this embodiment is connected to the concrete frame beam, which is composed of an anchor piece anchored in the concrete frame beam 1 and a gusset plate 5 placed at the lower part of the concrete frame beam 1, wherein the anchor piece consists of a group (this embodiment is Five) H-shaped steel 3, upper anchor plate 2, and lower anchor plate 4. The inner edges of the upper anchor plate 2 and the lower anchor plate 4 are outside the concrete frame beam 1, and the length ratio of the upper anchor plate 2 and the lower anchor plate 4 is The transverse width of the gusset plate 5 is 200 mm more. The whole node component is made in the factory: five H-shaped steels are symmetrically arranged between the upper anchor plate 2 and the lower anchor plate 4, and the upper and lower ends of the H-shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com