Reinforced concrete frame gridding slab prefabricated energy-saving house

A technology of reinforced concrete and prefabricated assembly, which is applied in the direction of construction and building construction, which can solve the problems of difficult movement, repeated use, inability to dismantle, difficult transportation and installation, etc., and achieve the effect of lightweight full assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

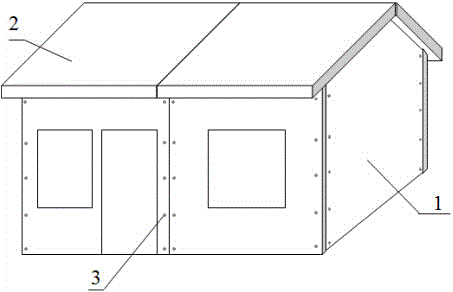

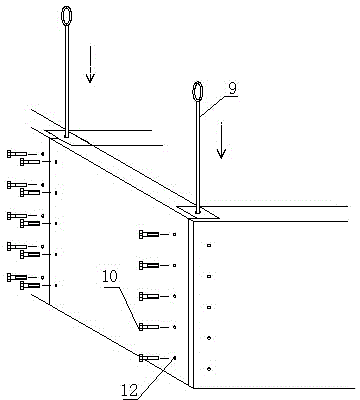

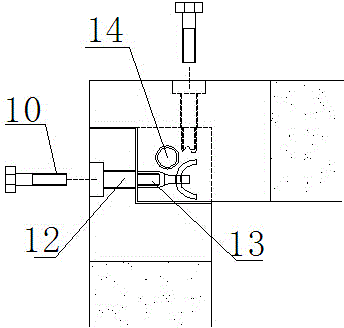

[0056] Embodiment 1: (single-storey house embodiment with sloping roof) see Figure 1-6 , figure 1 An axonometric drawing of a prefabricated house. The house is composed of a sash concrete lightweight wall panel (1), a sash concrete roof panel (2) and connecting fittings (3). figure 2 It is the dismantling diagram of the components of Example 1, (4) is the sash assembled lightweight wall panel, (5) is the sash roof panel, and the sash concrete wall panel and the floor slab roof panel are surrounded by different types of bites ( 6) The reinforced concrete slab frame (7) and the foam concrete (8) in the slab frame frame are composed. After the two slabs are interlocked and occluded, they are tied by the long pin bars (9) and fixed by the fixing bolts (10). The shear pin block (11) is used to improve the shear resistance of the seam. image 3 , Figure 4 It is a fixing method after two (or 3) wallboards are occluded. After the occlusal, the vertical reserved holes of the o...

Embodiment 2

[0057] Embodiment 2 (manufacturing method 1 of sash wall panel and floor slab roof panel), see Figure 7 - 9, Figure 7 It is the assembly diagram of the combined mold for the prefabrication of sash concrete wall panels and floor slab roof panels. The combined mold is mainly composed of a surrounding frame (19) (20) and a bite module (21) (22) fixed on the surrounding frame. Figure 8 is a schematic diagram of the combined abrasive tool bite module (22), the bite module is fixed (or welded) on the surrounding frame with fixing bolts, and the foam concrete block (23) is placed in the plate frame surrounded by the combined mold, and fixed at the design position Hole-reserved plastic pipe (24) (25), fix the pre-embedded fixture with internal thread on the mold, and the plastic pipe (24) with the reserved pin hole passes through the long steel bar (26) passing through the bite module and the plastic pipe )fixed. Figure 8 It is a schematic diagram of the reinforcement of the s...

Embodiment 3

[0058] Embodiment 3 (the manufacturing method of sash wall panels and floor slab roof panels) see Figure 10-11 , Figure 10 It is a schematic diagram of a reinforced concrete frame frame. The foam concrete block (23) in Example 2 is replaced by a formwork. First, a frame (31) with a bite (30), a longitudinal rib (32), and a transverse rib ( 33) The reinforced concrete sash frame (7) formed, forms the gap (34) between the concrete sash after the formwork is removed. Figure 11 It is a schematic diagram of pouring foam concrete into the gap of the frame. After the concrete slab (7) is cured to a certain strength, a low surrounding formwork (34) is made on the outer edge of the outer frame, and the foam concrete (35) is poured into the slab. Foamed concrete can be used as a reinforced insulation layer (36) covering the entire slab surface by a certain thickness higher than the slab frame, Figure 10 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com