Compound key overflow weir type siphon well and method implemented by same

A technology of siphon wells and overflow weirs, which is applied in the direction of waterway systems, drainage structures, water supply devices, etc., can solve the problems of insufficient mainstream diffusion distance, poor flow state in the upstream of siphon wells, and bringing into downstream box culverts, etc., to achieve enhanced single width The effect of flow capacity, reduction of slump drop, and suppression of mixing bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

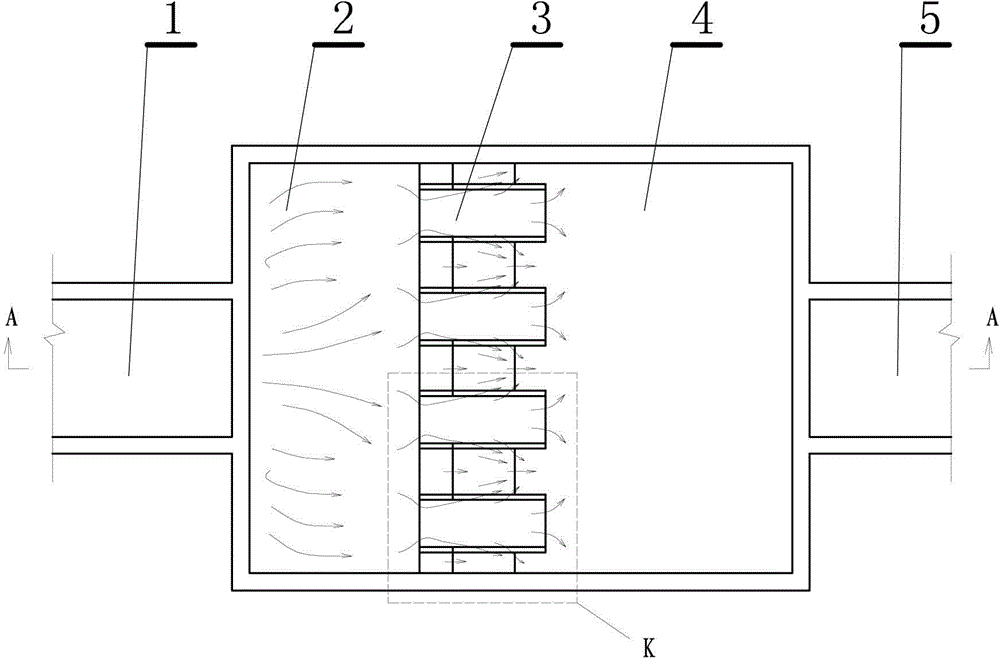

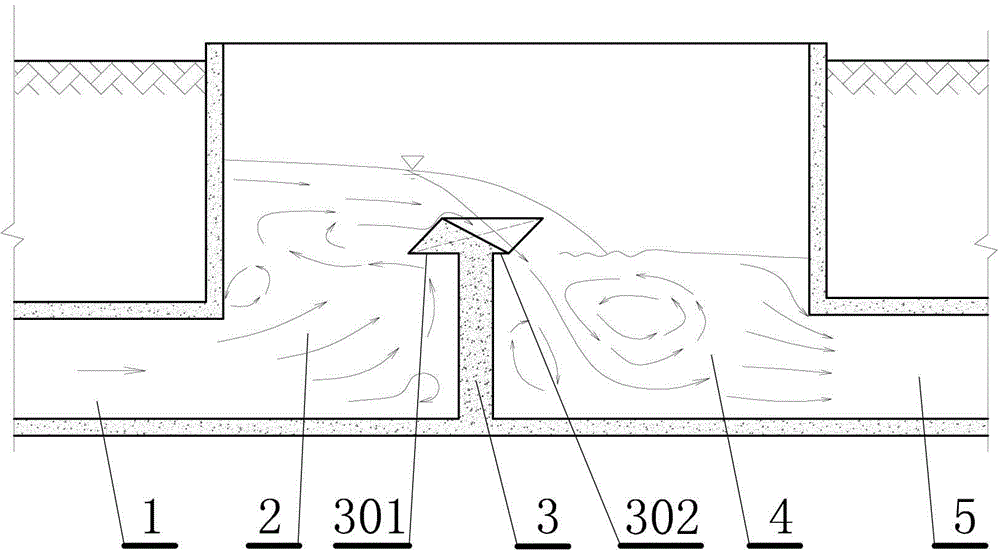

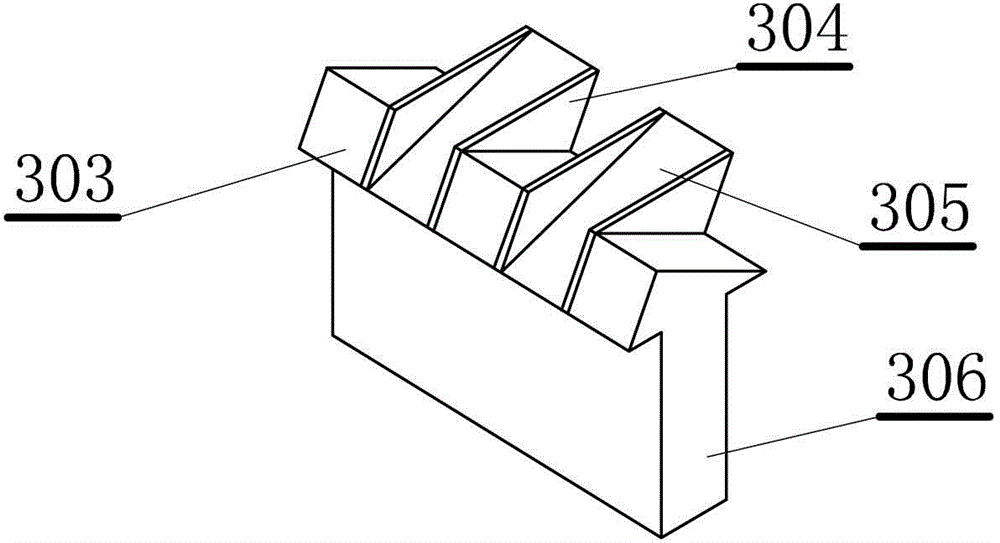

[0033] The present embodiment is a composite piano overflow weir type siphon well, such as figure 1 , 2 , 3, 4, and 5. This embodiment includes: at least one single well combination, the single well combination includes a vertical shaft 2 with an inlet culvert 1, the vertical shaft is connected to an overflow connection well 4, and the overflow connection well is connected to The water delivery culvert pipe 5 is connected, and a composite keyboard overflow weir 3 is provided between the shaft and the overflow connection well, see figure 1 , 2 . Described composite key overflow weir, such as figure 2 As shown, it includes: a weir body 306, the top of the weir body is staggered with positive triangular piers 303 and reverse triangular piers 305 with a horizontal bottom surface, and the bottom surfaces of the forward triangular piers and reverse triangular piers are along the direction of water flow. The length exceeds the thickness of the top of the weir body, forming a we...

Embodiment 2

[0043] This embodiment is an improvement of the first embodiment, and it is a refinement of the first embodiment about the forward and reverse triangular piers and the partition. The water-facing surface of the forward triangular pier described in this embodiment is parallel to the backwater surface of the reverse triangular pier, and the shape of the partition plate is a parallelogram conforming to the section of the forward triangular pier and the reverse triangular pier along the water flow direction. Such as Figure 5 shown.

[0044] The shape of the parallelogram partition is determined by the shape of two triangular piers, or conversely, the two bases and two hypotenuses of the partition determine the ground, the water-facing surface and the back-water surface of the two triangular piers Angle.

Embodiment 3

[0046] This embodiment is an improvement of the above embodiment, and is a refinement of the above embodiment on the forward and reverse triangular piers. The bottom angle facing the water of the forward triangular pier described in this embodiment is greater than that of the reverse triangular pier.

[0047] The specific effect produced by such a situation is: the water-facing surface of the forward triangular pier is relatively steep, while the water-facing surface of the reverse triangular pier is relatively gentle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com