Foamed bitumen generating spraying device

A technology of foamed asphalt and spraying device, which is applied in the direction of roads, road repairs, roads, etc., can solve the problems of poor asphalt mixing effect, achieve the effect of improving foaming effect, low price, and preventing outlet blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

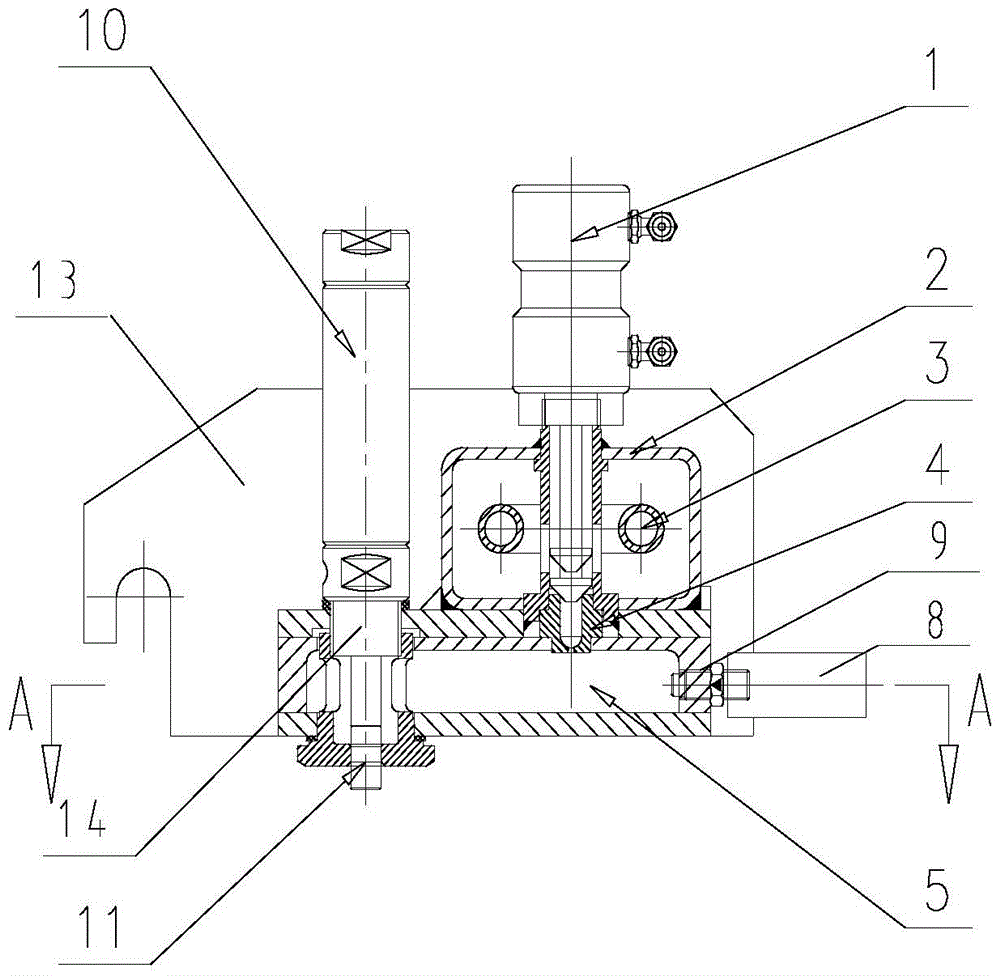

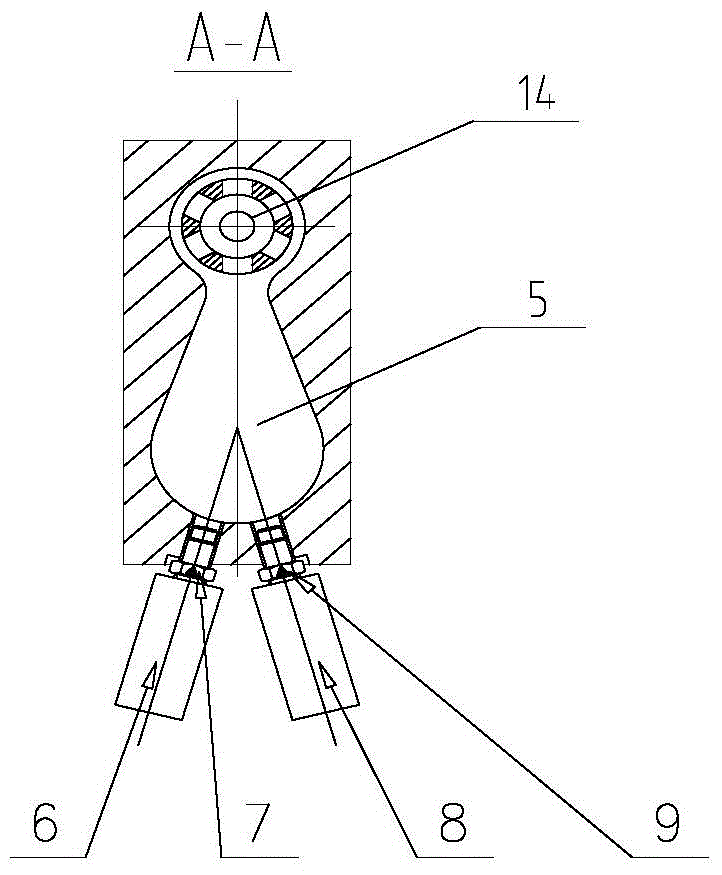

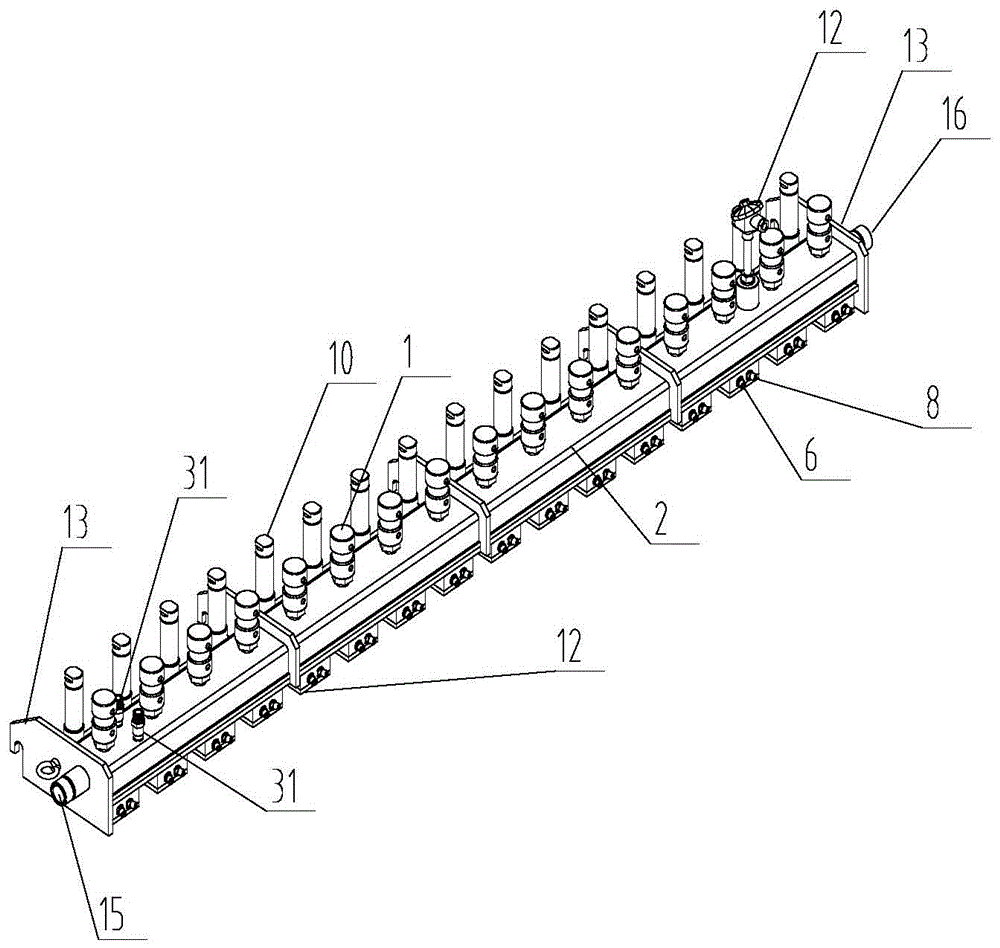

[0024] see Figure 1 to Figure 4 , the foamed asphalt generation spraying device of the present invention comprises a hot asphalt spraying chamber 2, 16 foaming units, 16 control units, a heating unit, a temperature sensor 12 arranged in the hot asphalt spraying chamber 2, a foaming water delivery pipeline and The foaming gas delivery pipeline; the hot asphalt spraying chamber 2 is a strip-shaped cavity with a length of at least 2.5m, and its two ends are respectively provided with a first interface 15 and a second interface 16; the first interface 15 and the second interface 16 are respectively It communicates with the asphalt conveying system; the foaming unit includes asphalt foaming chamber 5, hot asphalt spraying control cylinder 1, asphalt nozzle, foamed asphalt spraying control cylinder 10, foamed asphalt outlet 11; foaming water delivery pipeline includes water tank, water pump, 8 The multi-way valve at the outlet, 16 foaming water one-way valves connected to the outle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com